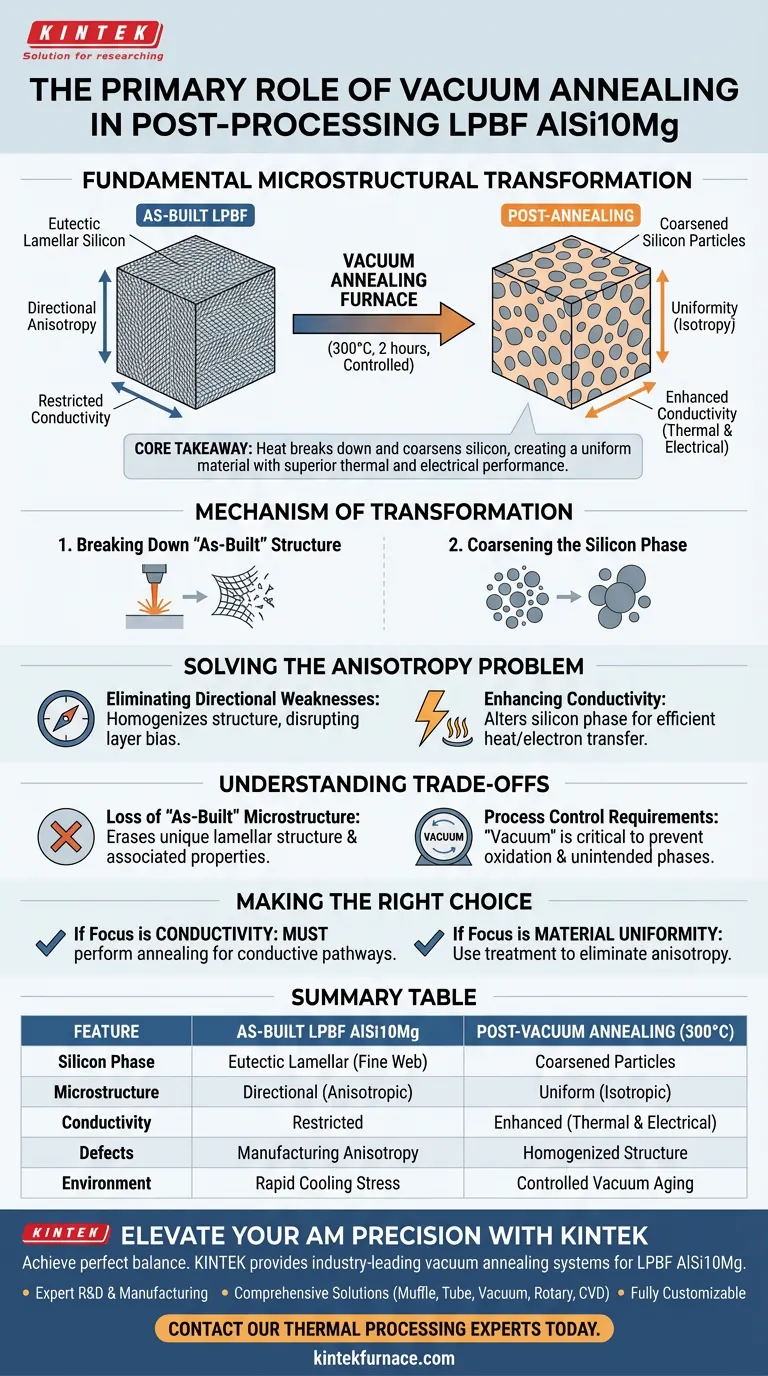

The primary role of a vacuum annealing furnace in post-processing AlSi10Mg is to fundamentally transform the alloy's microstructure, specifically targeting the silicon phase. By subjecting the material to a controlled high-temperature environment (typically 300°C for 2 hours), the furnace drives the redistribution of silicon into coarser particles, which eliminates directional manufacturing defects and enhances conductivity.

Core Takeaway The "as-built" LPBF structure suffers from internal directionality (anisotropy) and restricted conductivity. Vacuum annealing corrects this by utilizing heat to break down and coarsen the silicon microstructure, resulting in a uniform material with superior thermal and electrical performance.

The Mechanism of Microstructural Transformation

Breaking Down the "As-Built" Structure

Directly after the Laser Powder Bed Fusion (LPBF) process, AlSi10Mg exhibits a specific "eutectic lamellar" silicon microstructure.

This initial structure is a byproduct of the rapid cooling rates inherent to laser printing.

The vacuum annealing furnace provides the thermal energy required to destabilize this structure, causing the silicon phase to break away from its lamellar form.

Coarsening the Silicon Phase

Once the initial structure is destabilized, the silicon does not simply disappear; it reorganizes.

Under heat treatment conditions of roughly 300°C for 2 hours, the silicon redistributes and aggregates.

This results in the formation of coarser, distinct silicon particles, replacing the fine, interconnected webs found in the printed part.

Solving the Anisotropy Problem

Eliminating Directional Weaknesses

One of the deep challenges with LPBF is "manufacturing anisotropy," where the material's properties vary depending on the direction in which they are measured.

This is caused by the layer-by-layer nature of the printing process and the resulting grain orientation.

The coarsening of silicon particles during annealing disrupts this directional bias, effectively homogenizing the material structure.

Enhancing Conductivity

The transformation to coarser silicon particles does more than just balance the material mechanically.

It significantly improves both thermal and electrical conductivity.

By altering the connectivity and shape of the silicon phase, the material allows for more efficient transfer of heat and electrons compared to the as-built state.

Understanding the Trade-offs

Loss of the "As-Built" Microstructure

It is important to recognize that this process is destructive to the initial printed lattice structure.

While you gain isotropy and conductivity, you are effectively erasing the unique eutectic lamellar structure created by the laser.

This means the material properties (such as hardness or yield strength) associated with that fine, rapid-cooled structure will be altered permanently.

Process Control Requirements

While the outcome is beneficial, the process demands precise environmental control.

As seen in other sensitive alloys (like Titanium or Sm-Co-Fe), deviations in temperature or atmosphere can lead to unintended phase changes or oxidation.

Therefore, the "vacuum" aspect is critical to ensure the transformation happens purely via thermal aging without introducing atmospheric contaminants.

Making the Right Choice for Your Project

To determine if this specific vacuum annealing schedule is right for your AlSi10Mg parts, consider your performance requirements:

- If your primary focus is Thermal or Electrical Conductivity: You must perform this annealing step to coarsen the silicon phase and open up conductive pathways.

- If your primary focus is Material Uniformity: Use this treatment to eliminate the manufacturing anisotropy inherent to the printing process.

Summary: Vacuum annealing transforms AlSi10Mg from a directionally-biased, printed component into a uniform, highly conductive material by physically restructuring its silicon phase.

Summary Table:

| Feature | As-Built LPBF AlSi10Mg | Post-Vacuum Annealing (300°C) |

|---|---|---|

| Silicon Phase | Eutectic Lamellar (Fine Web) | Coarsened Particles |

| Microstructure | Directional (Anisotropic) | Uniform (Isotropic) |

| Conductivity | Restricted | Enhanced (Thermal & Electrical) |

| Defects | Manufacturing Anisotropy | Homogenized Structure |

| Environment | Rapid Cooling Stress | Controlled Vacuum Aging |

Elevate Your Additive Manufacturing Precision with KINTEK

Achieving the perfect balance of conductivity and structural uniformity in LPBF AlSi10Mg requires uncompromising thermal control. KINTEK provides industry-leading vacuum annealing systems designed to eliminate anisotropy and optimize your material properties.

Why Choose KINTEK?

- Expert R&D & Manufacturing: Our systems are engineered for the rigorous demands of post-processing sensitive alloys.

- Comprehensive Solutions: From Muffle and Tube furnaces to specialized Vacuum, Rotary, and CVD systems.

- Fully Customizable: We tailor high-temp lab furnaces to your unique metallurgical specifications.

Don't let manufacturing defects compromise your components. Contact our thermal processing experts today to discover how our high-performance furnace systems can refine your production workflow.

Visual Guide

References

- Martin Sarap, Toomas Vaimann. Electrical and Thermal Anisotropy in Additively Manufactured AlSi10Mg and Fe-Si Samples. DOI: 10.3390/machines13010001

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What role does a vacuum sintering furnace play in the formation of the 'core-rim' structure in Ti(C,N)-FeCr cermets?

- Why is a double-chamber device preferred over a standard electric furnace for sintering? Achieve Oxidation-Free Results

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density