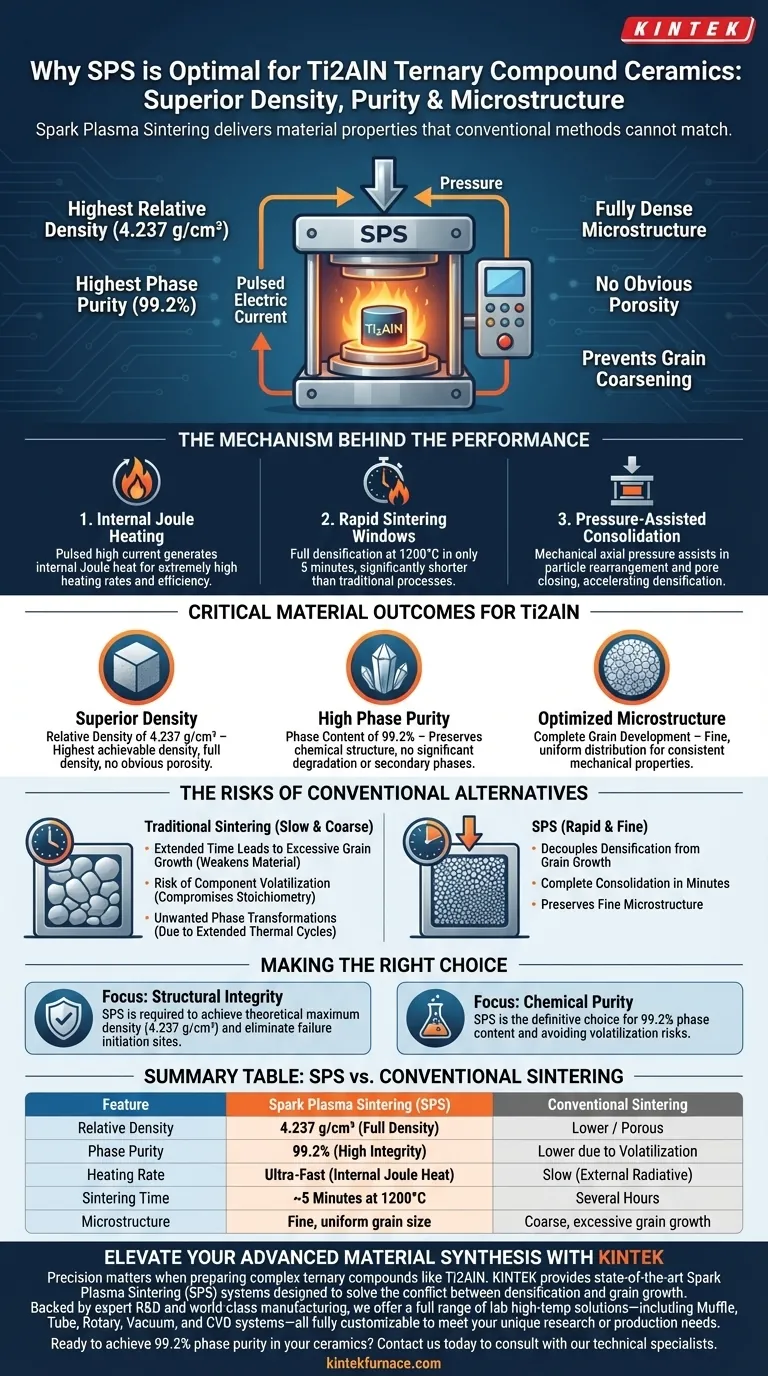

Spark Plasma Sintering (SPS) is considered the optimal choice for preparing Ti2AlN ternary compound ceramics because it delivers superior material properties that conventional methods cannot match. Specifically, SPS achieves the highest relative density (4.237 g/cm³) and phase purity (99.2%) by utilizing rapid heating and concurrent pressure. This process produces a fully dense microstructure with no obvious porosity while preventing the grain coarsening typical of traditional sintering.

SPS fundamentally solves the conflict between densification and grain growth. By generating internal Joule heat via pulsed electric current, it allows for complete consolidation in minutes rather than hours, preserving the material's fine microstructure.

The Mechanism Behind the Performance

SPS operates on principles distinct from conventional external heating, which is key to its success with complex compounds like Ti2AlN.

Internal Joule Heating

Unlike radiative heating, SPS passes a pulsed high current directly through the mold and the sample powder. This generates internal Joule heat, resulting in extremely high heating rates and high thermal efficiency.

Rapid Sintering Windows

This efficiency allows Ti2AlN to reach full densification very quickly. The process requires holding the material at 1200°C for only 5 minutes, a duration significantly shorter than traditional processes.

Pressure-Assisted Consolidation

SPS applies mechanical axial pressure simultaneously with the electric current. This mechanical force assists in rearranging particles and closing pores, further accelerating the densification process.

Critical Material Outcomes for Ti2AlN

The physical properties of the final ceramic are directly improved by the unique processing environment of the SPS equipment.

Superior Density

The combination of pressure and rapid heat yields a relative density of 4.237 g/cm³. This is the highest density achievable among common preparation methods, resulting in a product with no obvious porosity.

High Phase Purity

SPS ensures the integrity of the compound, achieving a phase content of 99.2%. This indicates that the chemical structure of the Ti2AlN is preserved without significant degradation or secondary phase formation.

Optimized Microstructure

The rapid processing time inhibits excessive grain growth. The result is a dense microstructure with complete grain development and a uniform distribution, ensuring consistent mechanical properties throughout the ceramic.

The Risks of Conventional Alternatives

To understand why SPS is "optimal," one must understand the trade-offs and pitfalls associated with the alternative, traditional sintering methods.

The "Time vs. Quality" Trap

Traditional sintering relies on long-term, high-temperature exposure to achieve density. However, for materials like Ti2AlN, this extended time often leads to excessive grain growth, which weakens the material.

Component Volatilization

Long-term heating increases the risk of component volatilization. Elements within the compound may evaporate or degrade before the ceramic is fully dense, compromising the stoichiometry.

Unwanted Phase Transformations

The extended thermal cycles of conventional methods can trigger undesirable phase transformations. SPS bypasses this by completing the densification process before these slow-moving transformations can occur.

Making the Right Choice for Your Goal

When selecting a preparation method for Ti2AlN, your choice should be dictated by your specific material requirements.

- If your primary focus is Structural Integrity: SPS is required to achieve the theoretical maximum density (4.237 g/cm³) and eliminate porosity that could act as failure initiation sites.

- If your primary focus is Chemical Purity: SPS is the definitive choice to maintain 99.2% phase content and avoid the volatilization risks associated with long-duration heating.

SPS remains the industry standard for Ti2AlN because it effectively decouples densification from grain growth, allowing for a harder, denser, and purer ceramic.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Conventional Sintering |

|---|---|---|

| Relative Density | 4.237 g/cm³ (Full Density) | Lower / Porous |

| Phase Purity | 99.2% (High Integrity) | Lower due to Volatilization |

| Heating Rate | Ultra-Fast (Internal Joule Heat) | Slow (External Radiative) |

| Sintering Time | ~5 Minutes at 1200°C | Several Hours |

| Microstructure | Fine, uniform grain size | Coarse, excessive grain growth |

Elevate Your Advanced Material Synthesis with KINTEK

Precision matters when preparing complex ternary compounds like Ti2AlN. KINTEK provides state-of-the-art Spark Plasma Sintering (SPS) systems designed to solve the conflict between densification and grain growth.

Backed by expert R&D and world-class manufacturing, we offer a full range of lab high-temp solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique research or production needs.

Ready to achieve 99.2% phase purity in your ceramics? Contact us today to consult with our technical specialists and find the perfect high-temperature solution for your lab.

Visual Guide

Related Products

- Spark Plasma Sintering SPS Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the essential requirements for a high-temperature vacuum furnace? Optimize Your Metal Solidification Research

- Why is a vacuum drying oven critical for moisture-sensitive batteries? Ensuring Stability in Potassium-Ion Systems

- What is the role of the temperature control system in a vacuum furnace? Achieve Precise Material Transformations

- How does a modern pressure sintering furnace operate? Unlock High-Density Materials with Precision

- What is the role of temperature control systems in a vacuum furnace? Ensure Precision in Heat Treatment Processes

- What is the leak rate for a vacuum furnace? Ensuring Process Integrity and Purity

- Why is it necessary to maintain a high vacuum for PrVSb3 single crystal preparation? Ensure Purity and Stoichiometry

- What role does a vacuum oven play in the activation process of Ce-MOF? Unlock Maximum Porosity and Surface Area