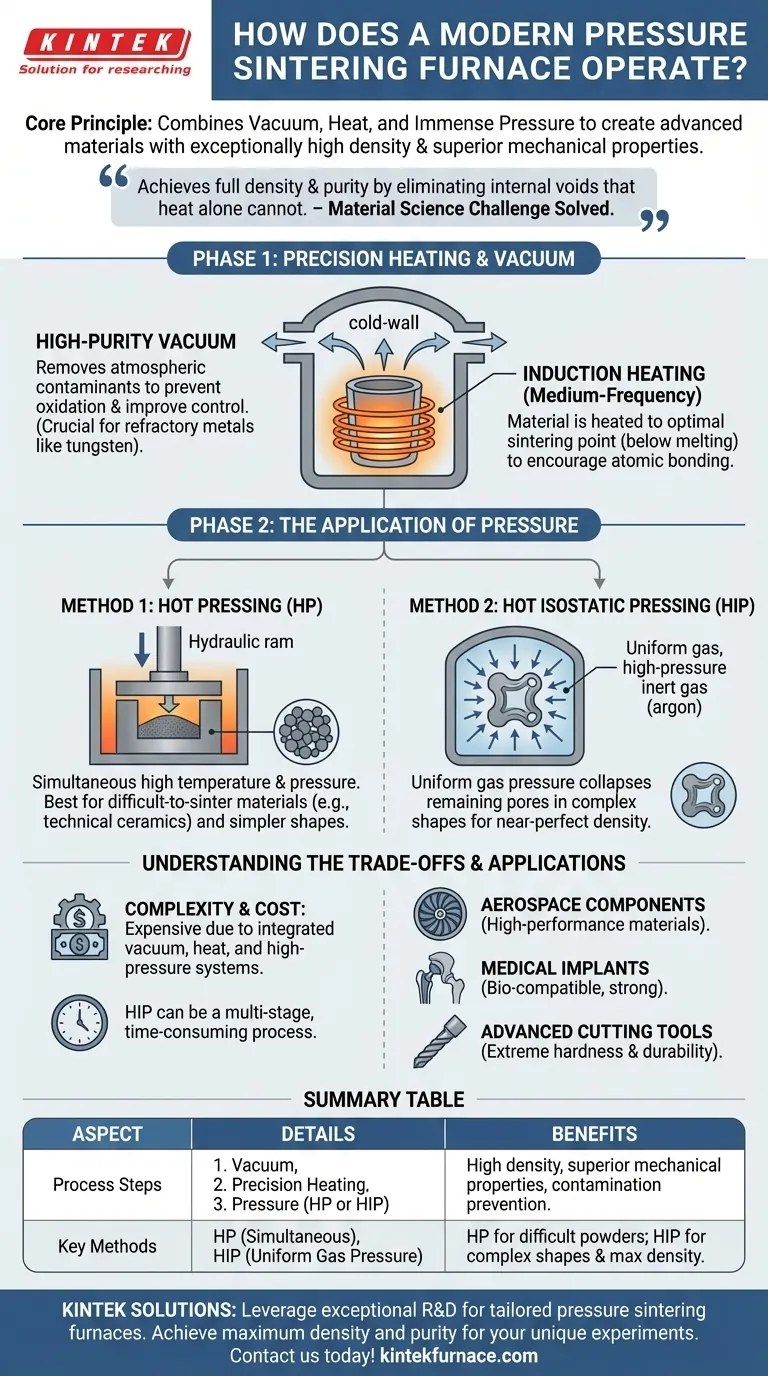

At its core, a modern pressure sintering furnace operates in a controlled sequence: it first heats materials in a high-purity vacuum to prevent contamination and then applies immense pressure to compact and solidify them. This combination of vacuum, heat, and pressure allows for the creation of advanced materials with exceptionally high density and superior mechanical properties that are impossible to achieve through heating alone.

The fundamental challenge in material science is achieving full density and purity. A pressure sintering furnace solves this by systematically removing atmospheric contaminants with a vacuum before using high temperatures and immense pressure to physically force material particles together, eliminating internal voids.

The Core Principle: Why Sintering Needs Pressure

What is Sintering?

Sintering is a process where a powdered material is heated to a temperature just below its melting point. At this temperature, the atoms in the particles diffuse across the boundaries of adjacent particles, fusing them together into a solid piece.

The goal is to create a dense, solid object from a powder. However, traditional sintering (using heat alone) often leaves behind small voids or pores, which can compromise the final material's strength and performance.

The Role of a Vacuum

The first critical step in a modern furnace is creating a high-purity vacuum. Pulling the atmospheric gases out of the chamber serves two vital purposes.

First, it prevents oxidation and contamination. Many advanced materials, especially refractory metals like tungsten, will react with oxygen at high temperatures, degrading their quality. A vacuum ensures the material remains pure.

Second, it improves process control. Removing air allows for a more stable and predictable heating environment, leading to a more consistent and reliable final product.

Deconstructing the Modern Furnace: A Step-by-Step Process

A modern pressure sintering furnace is a sophisticated "cold-wall" vessel. This means the furnace body itself is actively cooled while only the internal heating elements and the workpiece get extremely hot, allowing for precise thermal management.

Phase 1: Precision Heating

Once a vacuum is established, the material is heated. This is typically done using a method like medium-frequency induction heating, where a powerful magnetic field heats a crucible (often made of tungsten or graphite) which then radiates heat to the workpiece.

The temperature is carefully raised to the material's optimal sintering point—hot enough to encourage atomic bonding but not hot enough to melt it.

Phase 2: The Application of Pressure

This is the defining stage of the process. Pressure is used to physically close the internal voids that heat alone cannot eliminate. There are two primary methods for applying this pressure.

Hot Pressing (HP): In this method, high temperature and high pressure are applied simultaneously. A physical ram presses down on the material powder within a die while it is being heated. This is particularly effective for materials like ceramics that are difficult to fuse.

Hot Isostatic Pressing (HIP): This is a more common approach for achieving near-perfect density. The material is first sintered in a vacuum (or at low pressure) to an initial density. Then, the furnace is backfilled with a high-pressure inert gas (like argon). This immense, uniform pressure collapses any remaining internal pores, resulting in a fully dense part.

Understanding the Trade-offs

Complexity and Cost

These furnaces are highly complex systems that integrate vacuum technology, high-temperature engineering, and high-pressure hydraulics or gas systems. This interdisciplinary nature makes them expensive to acquire, operate, and maintain.

Hot Pressing vs. Hot Isostatic Pressing

Hot Pressing is excellent for compacting powders that resist sintering but is often limited to simpler shapes due to the use of a physical die and ram.

Hot Isostatic Pressing (HIP) can be applied to complex shapes because the gas pressure is uniform (isostatic) from all directions. However, it is a multi-stage process and can be more time-consuming.

Material Suitability

While transformative, pressure sintering is not a universal solution. It is most beneficial for high-performance materials where achieving maximum density and purity is critical to function, such as in aerospace components, medical implants, and advanced cutting tools. For less demanding applications, conventional sintering may be sufficient.

Making the Right Choice for Your Goal

When considering this technology, your final objective dictates the best approach.

- If your primary focus is achieving maximum theoretical density in complex parts: The two-stage process of vacuum sintering followed by Hot Isostatic Pressing (HIP) is the definitive method.

- If your primary focus is consolidating difficult-to-sinter powders like technical ceramics: The Hot Pressing (HP) method, which applies pressure during heating, is often the more effective choice.

- If your primary focus is ensuring the highest material purity: The vacuum stage is the most critical element, as it eliminates the risk of oxidation and contamination during the high-temperature cycle.

By mastering the interplay of vacuum, heat, and pressure, these furnaces empower engineers to design and create materials with properties that were previously unattainable.

Summary Table:

| Aspect | Details |

|---|---|

| Process Steps | 1. Vacuum creation for purity 2. Precision heating 3. Pressure application (HP or HIP) |

| Key Methods | Hot Pressing (HP): Simultaneous heat and pressure Hot Isostatic Pressing (HIP): Uniform gas pressure for complex shapes |

| Benefits | High density, superior mechanical properties, contamination prevention |

| Applications | Aerospace components, medical implants, advanced cutting tools |

Ready to enhance your material science projects with advanced high-temperature furnace solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with tailored pressure sintering furnaces, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for achieving maximum density and purity. Contact us today to discuss how our solutions can drive your innovations forward!

Visual Guide

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the primary function of high-purity quartz sealed tubes? Master Sb-Te Alloy Synthesis with Precision Isolation

- What industrial and research applications are tube furnaces used for? Unlock Precise Thermal Processing Solutions

- What materials are used for the tubes in a High Temperature Tube Furnace? Choose the Right Tube for Your Lab

- What is the significance of porcelain furnaces in academic and scientific research? Unlock Innovation with Precise High-Temperature Control

- What is the function of high-vacuum encapsulated quartz tubes for Ce2(Fe, Co)17? Ensure Phase Purity and Stability