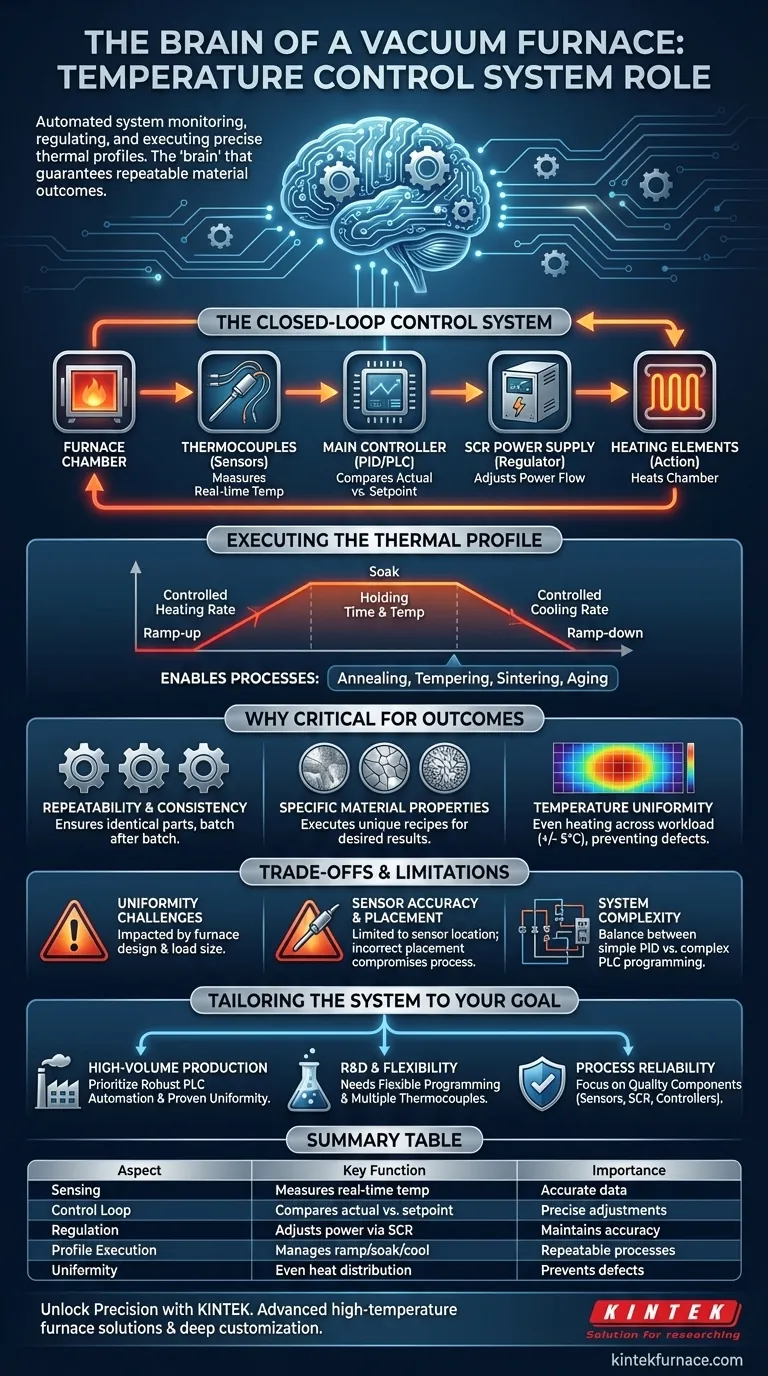

At its core, the temperature control system is the brain of a vacuum furnace. It is the automated system responsible for monitoring, regulating, and executing the precise thermal profile required for a given process. Using sensors and controllers, it dictates the heating rate, holding time (soak), and cooling rate to transform a material's properties according to a strict, predetermined plan.

The true role of the temperature control system extends beyond simply reaching a set temperature. It is about flawlessly executing a complex thermal recipe to guarantee specific, repeatable, and verifiable material outcomes in a controlled vacuum environment.

How the Temperature Control System Achieves Precision

A vacuum furnace's ability to deliver consistent results is entirely dependent on a closed-loop control system. This system continuously measures, compares, and adjusts to maintain the exact conditions required by the process.

Sensing: The Role of Thermocouples

The process begins with measurement. Thermocouples are robust sensors placed inside the furnace chamber to get a direct, real-time reading of the temperature in the hot zone.

These sensors are connected via specialized compensation wire to the main controller, ensuring the signal remains accurate and is not distorted by temperature changes outside the furnace.

The Control Loop: From Signal to Action

The signal from the thermocouple is fed back to the main temperature controller, which can be a PID programmer, a touch screen interface, or a fully automated PLC system.

The controller constantly compares the actual temperature from the thermocouple to the desired temperature setpoint of the programmed recipe. This comparison happens many times per second.

Regulating Power: The Controller and Heating Elements

Based on the difference between the actual and setpoint temperatures, the controller precisely adjusts the power delivered to the furnace's heating elements.

This is typically managed by an SCR (Silicon Controlled Rectifier) Power Supply, which can finely modulate the flow of electricity. If the furnace is too cool, the controller increases power; if it's too hot, it reduces power, achieving control with nominal accuracy of +/- 1°C.

Executing the Thermal Profile

This control loop does more than just hold a single temperature. It manages the entire thermal profile, which includes:

- Ramp-up: Heating the material at a controlled rate.

- Soak: Holding the material at a specific temperature for a set duration.

- Ramp-down: Cooling the material at a controlled rate.

This precise execution is what enables metallurgical processes like annealing, tempering, sintering, and aging treatment.

Why This Control is Critical for Material Outcomes

The vacuum creates a pure environment, but the temperature control system performs the actual transformation. Without this precision, the process would be unreliable and produce inconsistent results.

Ensuring Repeatability and Consistency

The goal of industrial heat treating is to produce identical parts, whether in the same batch or a year apart. By adhering to a validated thermal profile with high accuracy, the control system ensures that every part achieves the same desired metallurgical structure and physical properties.

Enabling Specific Metallurgical Processes

Different materials and desired outcomes require vastly different thermal recipes. For example, annealing requires a slow cool-down to soften metal, while tempering involves heating to a lower temperature to increase toughness. The control system makes executing these unique, complex profiles possible.

Achieving Temperature Uniformity

Beyond accuracy at a single point, the system is critical for achieving temperature uniformity (e.g., +/- 5°C) across the entire workload. Proper control, combined with good furnace design, ensures that a large part or a full basket of small parts are heated evenly, preventing defects and inconsistencies.

Understanding the Trade-offs and Limitations

While powerful, a temperature control system is not infallible. Understanding its limitations is key to successful operation.

Temperature Uniformity Challenges

Achieving perfect temperature uniformity, especially in a large furnace, is a significant engineering challenge. The placement of heating elements, the design of the furnace (hot wall vs. cold wall), and the size of the load all impact how evenly the heat is distributed.

Sensor Accuracy and Placement

The entire system's accuracy is fundamentally limited by its sensors. A thermocouple's reading is only valid for its exact location. Incorrect placement can lead to the workpiece being at a different temperature than the controller believes, compromising the process.

Control System Complexity

There is a trade-off between simplicity and capability. A basic PID (Proportional-Integral-Derivative) controller is reliable for simple soak cycles. However, complex multi-step processes with different ramps and soaks benefit from a more advanced PLC (Programmable Logic Controller), which requires more sophisticated programming and setup.

Making the Right Choice for Your Goal

The emphasis you place on different aspects of the temperature control system should align with your primary objective.

- If your primary focus is high-volume production: Prioritize a system with robust PLC automation and proven temperature uniformity across the entire hot zone to ensure batch-to-batch consistency.

- If your primary focus is research and development: You need a system with flexible programming and the capability to add multiple thermocouples to precisely map and monitor experimental processes.

- If your primary focus is process reliability: Focus on the quality of core components like the thermocouples, SCR power supply, and brand-name controllers, as their failure directly compromises the integrity of the heat treatment cycle.

Ultimately, mastering the temperature control system is mastering the art of transforming materials with absolute precision.

Summary Table:

| Aspect | Key Function | Importance |

|---|---|---|

| Sensing | Uses thermocouples to measure real-time temperature | Provides accurate data for control |

| Control Loop | Compares actual vs. setpoint temperatures | Enables precise adjustments |

| Regulation | Adjusts power to heating elements via SCR | Maintains temperature accuracy |

| Profile Execution | Manages ramp-up, soak, and ramp-down phases | Ensures repeatable thermal processes |

| Uniformity | Achieves even heat distribution across workload | Prevents defects and inconsistencies |

Unlock Precision in Your Laboratory with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're focused on high-volume production, research and development, or process reliability, our expertise ensures flawless thermal control for consistent material outcomes.

Contact us today to discuss how our tailored furnace systems can enhance your lab's efficiency and accuracy!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What technological features enhance the efficiency of vacuum furnaces? Boost Performance with Advanced Control & Energy Savings

- Why is a water cooling system necessary in a vacuum furnace? Ensure Safety and Performance in High-Temp Processes

- Why use a high-temp annealing furnace for Fe–32Ni alloy heat treatment? Achieve Microstructural Consistency

- Why is a vacuum annealing furnace superior to air annealing for ZnSe/SiO2/Si? Protect Your Semiconductor Integrity

- What are the advantages of using multi-stage programmed heating for copper-iron sintering? Enhance Material Integrity

- What are the steps in the discharge plasma sintering process? Master Fast, High-Density Material Consolidation

- What are the key steps in the working principle of a vacuum furnace? Master Precision Heat Treatment for Superior Results

- How do vacuum-based systems like PLD and Magnetron Sputtering contribute to superconducting thin films? Expert Guide