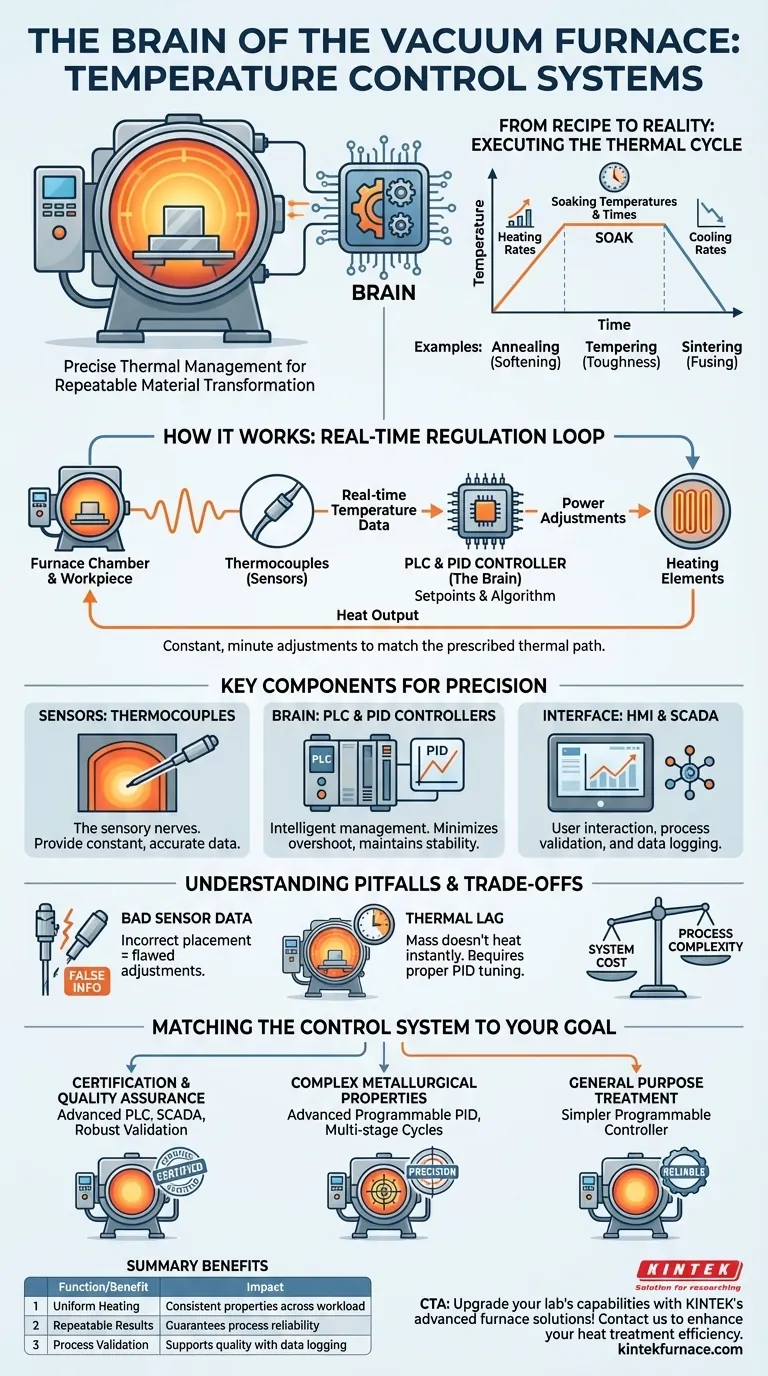

At its core, the role of a temperature control system in a vacuum furnace is to precisely monitor, regulate, and execute a specific thermal profile. This ensures that a workpiece is heated, held (or "soaked"), and cooled at exact temperatures for predetermined durations, guaranteeing consistent, repeatable results for processes like annealing, tempering, and sintering.

The temperature control system is the brain of the vacuum furnace. Without its ability to precisely manage the thermal cycle, it is impossible to reliably transform raw materials into components with the specific, desired metallurgical properties required for high-performance applications.

The Core Function: Achieving Repeatable Material Transformation

The primary purpose of a vacuum furnace is to alter the physical properties of a material through a controlled thermal process. The temperature control system is the mechanism that makes this transformation predictable and repeatable.

From Recipe to Reality

Heat treating is like following a recipe. The control system, often managed by a Programmable Logic Controller (PLC), executes this recipe, which consists of heating rates, soaking temperatures, hold times, and cooling rates. This precision is what enables critical processes like annealing (softening metal), tempering (increasing toughness), or sintering (fusing powder into a solid mass).

The Principle of Real-Time Regulation

The system does not simply turn the heat on and off. It continuously monitors the furnace's internal temperature and compares it to the desired setpoint in the program. It then makes constant, minute adjustments to the heating elements to ensure the workpiece follows the prescribed thermal path Wachstumsexactly.

Ensuring Uniformity Across the Workload

For a process to be successful, the entire workpiece, or "charge," must experience the same temperatures. Furnace designs allow for the strategic placement of thermocouples throughout the heating chamber, ensuring there are no hot or cold spots that could lead to inconsistent material properties.

Key Components of a Modern Control System

A modern temperature control system is an integrated network of sensors, logic controllers, and interfaces that work in concert to deliver precise results.

The Sensors: Thermocouples

Thermocouples are the sensory nerves of the system. These robust temperature sensors are placed inside the furnace, often in direct contact with or very near the workpiece, to provide a constant stream of accurate, real-time temperature data to the controller.

The Brain: PLCs and PID Controllers

A Programmable Logic Controller (PLC) acts as the central processor, managing the overall furnace functions and executing the programmed heat treatment cycle. It uses a PID (Proportional-Integral-Derivative) control algorithm to intelligently manage the heating elements, minimizing temperature overshoot and maintaining stability.

The Interface: HMI and SCADA

The operator interacts with the system through a Human-Machine Interface (HMI), typically an LCD touch-screen. This allows for programming cycles, monitoring progress, and managing alarms. For advanced traceability, these systems often integrate with SCADA (Supervisory Control and Data Acquisition), enabling process validation, data logging for quality reports, and multi-level operator security.

Understanding the Pitfalls and Trade-offs

While powerful, the effectiveness of a temperature control system is dependent on its configuration and the physical realities of heat transfer.

The System Is Only as Good as Its Data

The most advanced controller cannot compensate for poor sensor data. Incorrect thermocouple placement or a malfunctioning sensor will provide false information, leading the controller to make the wrong adjustments and potentially ruin the entire batch.

The Challenge of Thermal Lag

A furnace and its workload have thermal mass, meaning they do not heat or cool instantly. A poorly tuned PID algorithm can lead to overshooting the target temperature or oscillating around it, compromising the integrity of the treatment process. Proper tuning is critical.

Process Complexity Dictates System Cost

The level of precision required dictates the system's complexity and cost. A simple furnace for non-critical tempering may use a basic programmable controller. In contrast, a furnace for aerospace or medical components requires a sophisticated, fully-automated PLC and SCADA system to meet stringent certification standards.

Matching the Control System to Your Goal

The right control system is the one that meets the specific tolerance, traceability, and complexity requirements of your heat treatment process.

- If your primary focus is process certification and quality assurance: You need a system with a PLC, SCADA integration, and robust features for process validation, data logging, and security.

- If your primary focus is achieving complex metallurgical properties: You need a system with advanced, programmable PID control algorithms that can execute multi-stage thermal cycles with high precision.

- If your primary focus is general-purpose heat treatment: A system with a simpler, yet reliable, programmable controller may be sufficient, but it will offer less precision and traceability.

Ultimately, the temperature control system transforms the vacuum furnace from a simple heated box into a precise metallurgical tool.

Summary Table:

| Component | Function |

|---|---|

| Thermocouples | Monitor real-time temperature for accurate control |

| PLC & PID Controllers | Execute and regulate thermal cycles with precision |

| HMI & SCADA | Provide user interface and data logging for traceability |

| Benefit | Impact |

| Uniform Heating | Ensures consistent material properties across the workload |

| Repeatable Results | Guarantees reliability in processes like annealing and sintering |

| Process Validation | Supports quality assurance with data logging and security |

Upgrade your lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization ensures precise temperature control tailored to your unique experimental needs, delivering consistent, repeatable results for processes like annealing and sintering. Contact us today to discuss how our expertise can enhance your heat treatment efficiency and reliability!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today