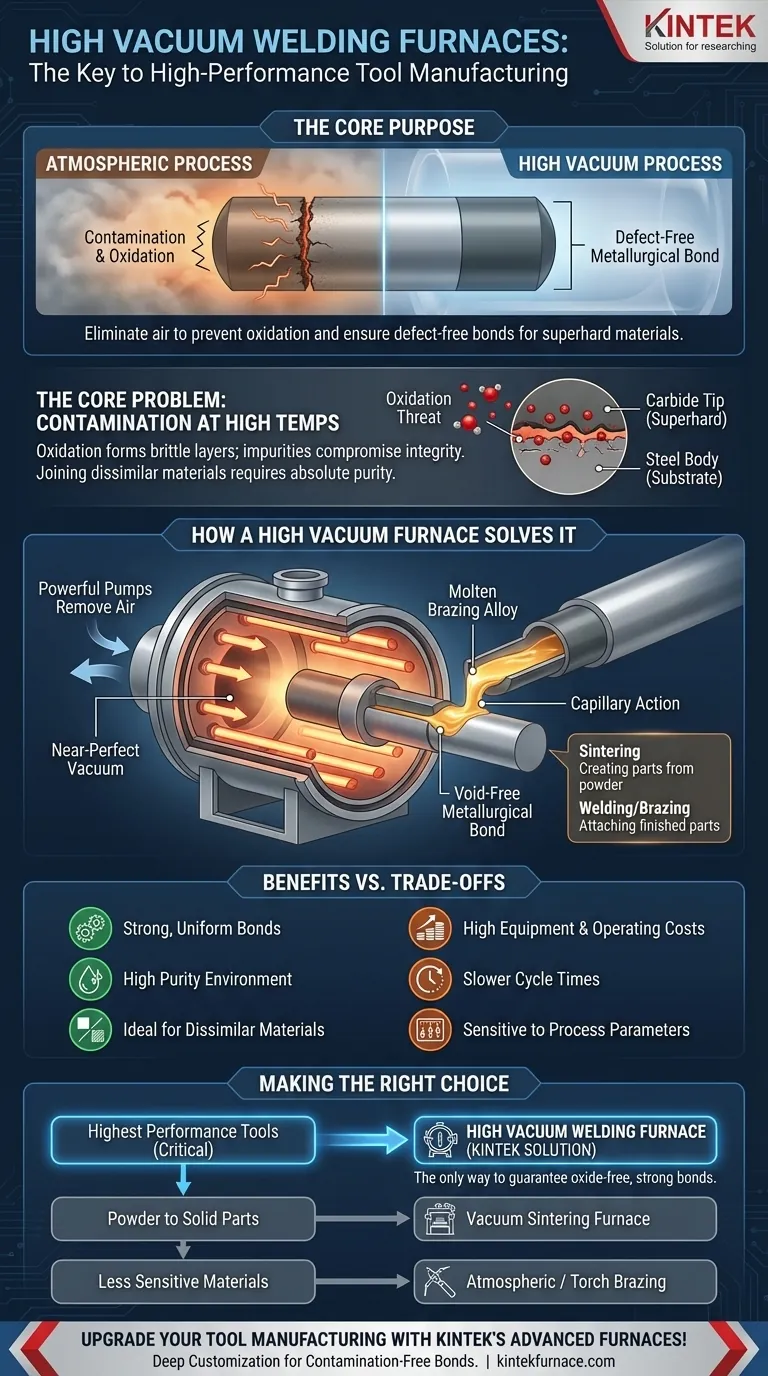

At its core, a high vacuum welding furnace provides an ultra-clean, controlled environment for joining superhard materials, like cemented carbide, to a substrate, such as a steel tool body. By removing virtually all atmospheric gases, the furnace prevents contamination and oxidation at high temperatures, ensuring the creation of a powerful, defect-free metallurgical bond that is essential for high-performance cutting tools.

The fundamental purpose of a high vacuum furnace is not the heat itself, but the elimination of air. It protects the metal surfaces from oxygen and other contaminants during the intense heat of the welding process, as even microscopic levels of contamination can lead to a weak bond and premature tool failure.

The Core Problem: Contamination at High Temperatures

To understand the necessity of a vacuum, you must first understand the enemy: the air around us. At the high temperatures required for welding and brazing, common atmospheric gases become highly reactive and destructive to the process.

The Threat of Oxidation

When metals are heated, they react rapidly with oxygen in the air. This process, oxidation, forms a thin, brittle layer of metal oxide on the surface.

Attempting to weld or braze oxidized surfaces is like trying to glue two pieces of dusty wood together. The bond will be to the weak, flaky oxide layer, not the strong parent material underneath, resulting in a joint that is destined to fail.

The Need for Absolute Purity

Beyond oxygen, other atmospheric elements and impurities can compromise the integrity of the weld. A high vacuum environment is the only practical way to achieve the level of cleanliness required.

This is why these furnaces often feature all-metal internal components and advanced molecular pump systems. These designs minimize "outgassing"—the release of trapped contaminants from the furnace walls themselves—to create a purer environment.

The Challenge of Joining Dissimilar Materials

Tool manufacturing often involves bonding a superhard but brittle cutting tip (like cemented carbide or PCD) to a tougher, more ductile steel body. These materials have different properties, and creating a seamless, durable connection between them is a significant engineering challenge that requires a perfect interface, free of any impurities.

How a High Vacuum Furnace Solves the Problem

A high vacuum furnace directly counteracts the threats of oxidation and contamination by fundamentally changing the environment in which the work is done.

Creating a Near-Perfect Vacuum

The furnace chamber is sealed and powerful pumps remove the air, reducing the internal pressure to a near-perfect vacuum. By removing the air molecules, the process starves the chemical reaction of oxidation before it can even begin.

Ensuring a Strong, Uniform Bond

In this clean, empty space, the brazing alloy used to join the materials melts and flows freely over the pure metal surfaces. This capillary action draws the alloy deep into the joint, creating a void-free, continuous metallurgical bond that is often as strong as the materials being joined.

Distinguishing Welding from Sintering

It is important to distinguish this process from vacuum sintering. Sintering is the process of creating the cemented carbide part itself from metal powders. Welding or brazing is the process of attaching that finished carbide part to a steel tool shank. While both benefit from a vacuum to prevent oxidation, they are distinct manufacturing steps.

Understanding the Trade-offs

While essential for high-quality results, high vacuum technology is not without its challenges and limitations. It represents a significant investment in both equipment and process control.

High Equipment and Operating Costs

High vacuum furnaces are complex, specialized machines. Their initial purchase price, installation, and ongoing maintenance are substantially higher than for conventional atmospheric furnaces.

Slower Process Cycle Times

Achieving a high vacuum is not instantaneous. The "pump-down" time to evacuate the chamber, followed by the controlled heating and cooling cycles, makes the overall process much slower than open-air brazing or welding methods.

Sensitivity to Process Parameters

The success of a vacuum weld is highly dependent on precise control over temperature, vacuum level, and the cleanliness of the parts being joined. Any deviation can compromise the quality of the final bond, requiring skilled operators and rigorous quality control.

Making the Right Choice for Your Goal

Selecting the correct thermal process depends entirely on the material requirements and performance expectations for the final product.

- If your primary focus is creating the highest-performance tools: A high vacuum furnace is non-negotiable for bonding superhard tips, as it is the only way to guarantee a bond free of weakening oxides and impurities.

- If your primary focus is processing metal powders into solid parts: A vacuum sintering furnace is the correct tool, using similar vacuum principles to prevent contamination during the densification process.

- If you are joining less sensitive materials where minor oxidation is acceptable: Simpler, less expensive methods like open-air torch brazing or an atmospheric furnace may be a sufficient and more cost-effective solution.

Ultimately, investing in a high vacuum environment is investing in the predictable quality and absolute reliability of the final tool.

Summary Table:

| Aspect | Details |

|---|---|

| Core Purpose | Provides ultra-clean, controlled environment for joining superhard materials to substrates, preventing contamination and oxidation. |

| Key Benefits | Ensures defect-free metallurgical bonds, essential for high-performance cutting tools; enables strong, uniform bonding of dissimilar materials. |

| Process Steps | Evacuates air to high vacuum, heats materials for welding/brazing, allows brazing alloy to flow freely for capillary action and void-free joints. |

| Trade-offs | High equipment and operating costs, slower cycle times, sensitivity to precise process parameters requiring skilled operation. |

| Ideal Use Cases | Bonding cemented carbide or PCD tips to steel bodies in tool manufacturing where absolute purity and reliability are critical. |

Upgrade your tool manufacturing with KINTEK's advanced high vacuum welding furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for contamination-free, high-performance bonds. Contact us today to discuss how our furnaces can enhance your production quality and efficiency!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness