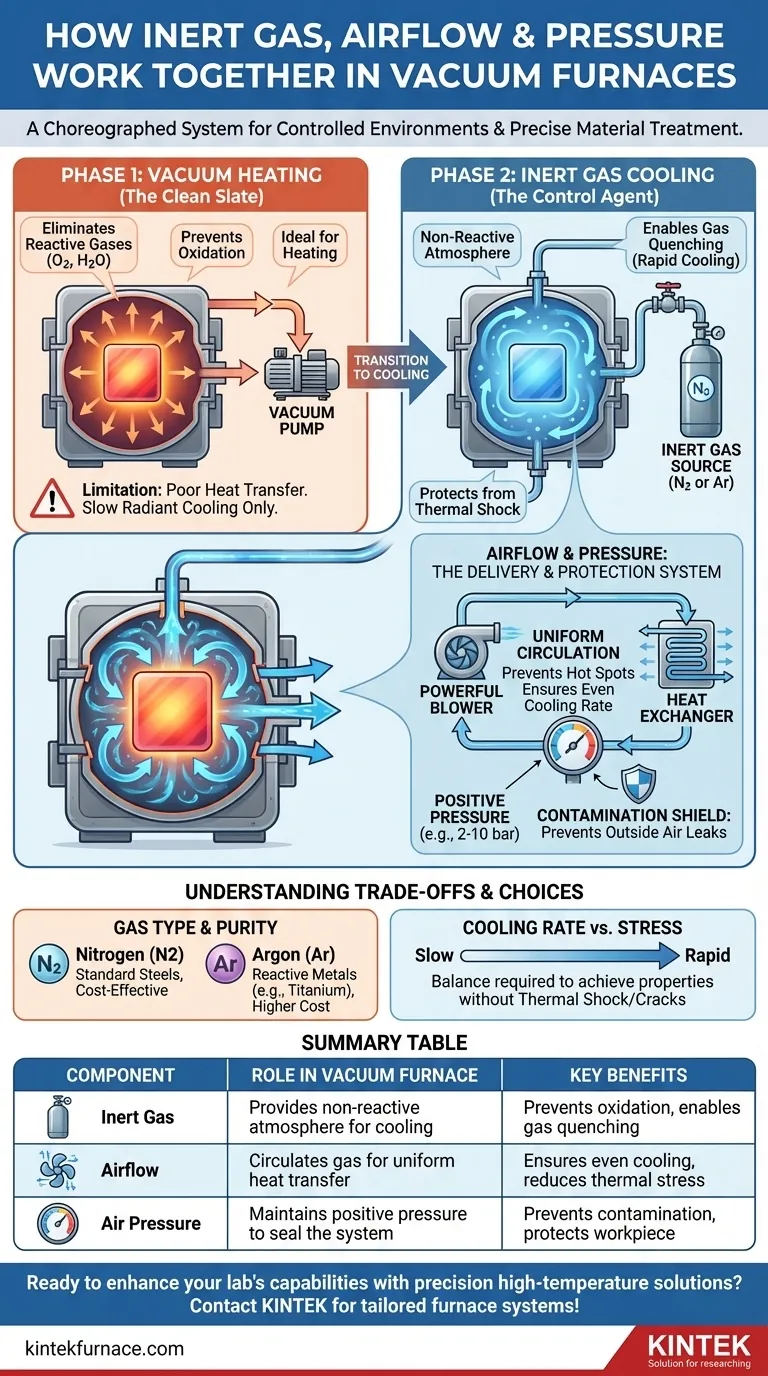

At its core, the relationship between inert gas, airflow, and internal pressure in a vacuum furnace is a carefully choreographed system designed to control the material's environment. After an initial vacuum removes reactive gases like oxygen, a non-reactive inert gas is introduced under specific pressure and flow conditions, primarily to manage rapid and uniform cooling without re-introducing contaminants.

The fundamental purpose is to transition from a pure vacuum—ideal for heating—to a controlled, non-reactive gas atmosphere that allows for rapid, uniform cooling. This dual-environment approach protects the workpiece from both oxidation during heating and thermal shock during cooling.

The Foundation: Why a Vacuum Is Only Half the Solution

A common misconception is that the vacuum itself performs all the work. In reality, it serves a specific, initial purpose: creating a clean slate.

Eliminating Reactive Gases

The primary function of pulling a vacuum is to remove the atmosphere, specifically oxygen and water vapor. At the extreme temperatures of a furnace, these elements would cause immediate and aggressive oxidation (rusting or scaling) and contamination of the workpiece.

By removing the air, the furnace creates an environment where materials can be heated without undergoing unwanted chemical reactions.

The Limitation of a Vacuum for Cooling

While a vacuum is perfect for preventing contamination during heating, it is a poor medium for transferring heat. Objects in a vacuum can only cool via radiation, which is a very slow process.

For many industrial applications, slow cooling is unacceptable as it limits throughput and fails to achieve specific metallurgical properties that depend on a rapid quench.

The Role of Inert Gas: The Control Agent

Once the heating cycle is complete, the inert gas system takes over. It's not just a filler; it's an active tool for thermal management.

Providing a Non-Reactive Atmosphere

Inert gases, most commonly nitrogen or argon, are used because their atomic structure makes them extremely non-reactive. They will not chemically bond with or alter the workpiece, even at high temperatures.

They effectively replace the hazardous reactive atmosphere with a safe, neutral one.

Enabling Rapid, Controlled Cooling

This process, often called gas quenching, is the primary function of inert gas technology. The system works in a closed loop.

A powerful blower circulates the inert gas out of the hot zone and through a heat exchanger, which cools the gas. This cooled gas is then forcefully reintroduced into the heating chamber.

The high-velocity flow of cool, inert gas rapidly absorbs heat from the workpiece, providing a controlled quench that is much faster than radiant cooling in a vacuum.

Airflow and Pressure: The Delivery and Protection System

Simply introducing inert gas isn't enough. How it is delivered (airflow) and maintained (pressure) is critical to the success of the process.

Airflow for Uniform Cooling

The term "airflow" here refers to the circulation of the inert gas, not outside air. The furnace is engineered with specific nozzles and pathways to ensure this gas flow is turbulent and uniform.

This uniformity prevents "hot spots" and ensures the entire workpiece cools at the same rate. Inconsistent cooling can introduce internal stresses, warping, or cracks in the final part.

Positive Pressure to Prevent Contamination

When the inert gas is backfilled into the furnace for quenching, it is typically done to a positive pressure (e.g., 2 to 10 bar or higher).

This positive internal pressure is a critical safeguard. It ensures that if any microscopic leaks exist in the furnace seals, the inert gas will flow out rather than allowing contaminated outside air to leak in.

Understanding the Trade-offs

Implementing an inert gas quenching system involves balancing performance, cost, and material compatibility.

Gas Type and Purity

Argon is more inert than nitrogen but is also significantly more expensive. For highly reactive metals like titanium, argon is often necessary to prevent any reaction. For most steels, the less expensive nitrogen is perfectly sufficient.

Cooling Rate vs. Thermal Stress

While rapid quenching is a major benefit, an excessively fast cooling rate can induce thermal shock, leading to cracks or dimensional instability in the part. The gas pressure and blower speed must be precisely controlled to match the material's tolerance.

System Complexity and Cost

A furnace with a high-pressure gas quench system is more complex and expensive than a simple vacuum-only furnace. It requires a robust vessel, a powerful blower, a large heat exchanger, and sophisticated controls, all of which increase capital and maintenance costs.

Making the Right Choice for Your Goal

The ideal furnace configuration depends entirely on your material and desired outcome. Use these principles to guide your thinking.

- If your primary focus is treating standard steels with minimal reactivity: A system using nitrogen at moderate pressures offers a cost-effective balance of performance and protection.

- If your primary focus is treating highly reactive metals like titanium or certain superalloys: A furnace capable of using high-purity argon is non-negotiable to prevent component-ruining reactions.

- If your primary focus is achieving specific metallurgical properties or high throughput: A system with high-pressure (6 bar or higher) quenching capabilities is essential for the rapid cooling required to lock in desired microstructures.

Mastering the interplay of vacuum, gas, and pressure transforms the furnace from a simple oven into a precision instrument for engineering materials.

Summary Table:

| Component | Role in Vacuum Furnace | Key Benefits |

|---|---|---|

| Inert Gas | Provides non-reactive atmosphere for cooling | Prevents oxidation, enables gas quenching |

| Airflow | Circulates gas for uniform heat transfer | Ensures even cooling, reduces thermal stress |

| Air Pressure | Maintains positive pressure to seal the system | Prevents contamination, protects workpiece |

Ready to enhance your lab's capabilities with precision high-temperature solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for optimal performance and efficiency. Contact us today to discuss how our tailored solutions can benefit your specific applications!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today