In short, vacuum chamber furnaces are essential because they create a perfectly controlled, contaminant-free environment. By removing the atmosphere, these furnaces prevent unwanted chemical reactions like oxidation and decarburization that occur at high temperatures. This absolute control results in superior material properties, pristine surface finishes, and unmatched consistency, which are non-negotiable requirements for high-performance industries like aerospace, medical, and advanced manufacturing.

The fundamental value of a vacuum furnace is not just what it does, but what it prevents. It eliminates atmospheric gases—the primary source of contamination and unpredictability in heat treatment—giving you complete authority over the material's final structure and performance.

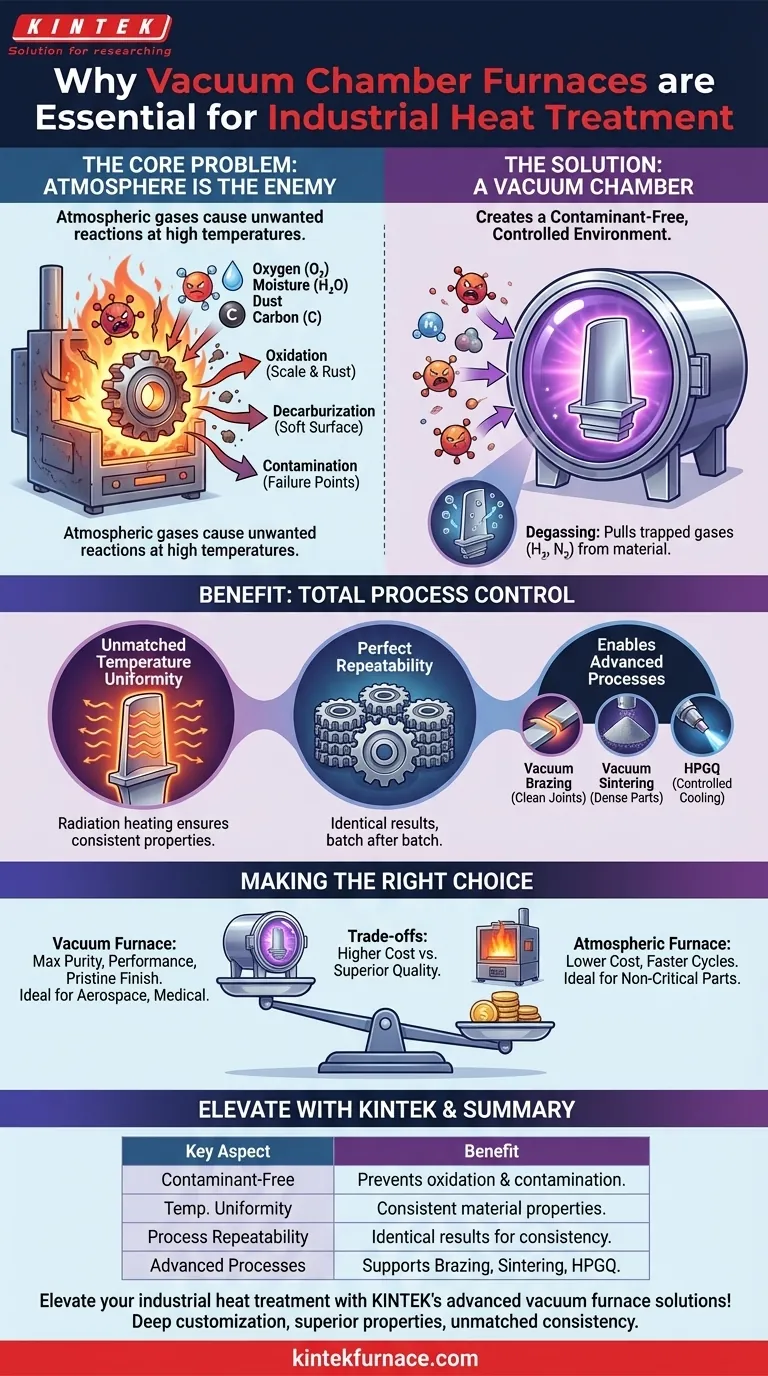

The Core Problem: Why Atmosphere is the Enemy

At the high temperatures required for heat treatment, the seemingly harmless air around us becomes a highly reactive agent. A vacuum furnace's primary job is to remove this variable from the equation.

Preventing Oxidation and Decarburization

When metals, especially steel, are heated, they react with oxygen in the atmosphere. This creates a layer of oxide scale on the surface, which ruins the finish and dimensional accuracy.

Simultaneously, the carbon within the steel can react with oxygen and escape the material's surface, a process called decarburization. This softens the surface layer, severely compromising the part's strength, wear resistance, and fatigue life. A vacuum eliminates the oxygen that drives both of these destructive reactions.

Eliminating Surface Contamination

Beyond oxygen, the atmosphere contains moisture, dust, and other trace gases. For sensitive applications like medical implants or aerospace turbine blades, even microscopic contamination can be a point of failure.

A vacuum chamber provides an ultra-clean environment, ensuring that the only thing touching the part is heat and, if required, a specific high-purity process gas.

Achieving Purity Through Degassing

A vacuum doesn't just protect the material's surface; it can improve its internal structure. The process actively pulls trapped gases, such as hydrogen and nitrogen, out from within the bulk material.

This degassing effect is critical for preventing issues like hydrogen embrittlement, a phenomenon that can cause catastrophic, brittle failure in high-strength metals.

The Benefit: Total Process Control

By removing the unpredictable atmosphere, you gain unprecedented control over every stage of the heat treatment cycle. This leads to superior quality and repeatability.

Unmatched Temperature Uniformity

In a vacuum, heat is primarily transferred through radiation, which is far more uniform than convection in open air. This ensures the entire part, regardless of its geometry, reaches the target temperature at the same time.

This temperature uniformity prevents internal stresses and guarantees consistent metallurgical properties—like hardness and grain structure—across the entire component.

Perfect Repeatability and Consistency

Atmospheric conditions like humidity and barometric pressure can vary daily, subtly altering the results of a heat treatment cycle. A vacuum furnace creates the exact same controlled environment every single time.

This invariance and repeatability are essential for industrial production, where the first part and the ten-thousandth part must be identical.

Enabling Advanced Processes

Many modern metallurgical processes are only possible in a vacuum. These include:

- Vacuum Brazing: Joining complex assemblies without flux, resulting in an incredibly strong, clean joint.

- Vacuum Sintering: Fusing powdered metals to create dense, near-net-shape parts with unique properties.

- High-Pressure Gas Quenching (HPGQ): Rapidly cooling parts with high-purity inert gas (like nitrogen or argon) to achieve specific hardness without the distortion risk associated with liquid quenching.

Understanding the Trade-offs

While powerful, a vacuum furnace is not the universal solution for all heat treatment needs. Objectivity requires acknowledging its limitations.

Higher Initial Cost and Complexity

Vacuum systems, with their associated pumps, seals, and control instrumentation, are significantly more expensive to purchase and maintain than standard atmospheric furnaces.

Potentially Longer Cycle Times

The process of pumping down the chamber to the required vacuum level takes time. For simple, low-value processes, the time added by the vacuum cycle may not be economically justifiable compared to a continuous atmospheric furnace.

Over-specification for Some Applications

If a part is going to be heavily machined after heat treatment, a small amount of surface oxidation or decarburization may be perfectly acceptable. In these cases, a less expensive atmospheric furnace is often the more pragmatic and cost-effective tool.

Making the Right Choice for Your Application

Selecting the right furnace technology depends entirely on your material, your budget, and the performance requirements of the final part.

- If your primary focus is maximum material purity and performance (aerospace, medical, high-performance tooling): A vacuum furnace is the only choice to guarantee contamination-free results and optimal mechanical properties.

- If your primary focus is a bright, clean surface finish with no post-processing: Vacuum heat treatment is essential to prevent oxidation and deliver a part that is ready to use immediately.

- If your primary focus is general-purpose heat treatment on a tight budget (non-critical components): A conventional atmospheric furnace may be more cost-effective, provided some surface scaling and post-process cleaning are acceptable.

Ultimately, choosing a vacuum furnace is an investment in certainty, precision, and the highest possible material quality.

Summary Table:

| Key Aspect | Benefit |

|---|---|

| Contaminant-Free Environment | Prevents oxidation, decarburization, and surface contamination for pristine finishes. |

| Temperature Uniformity | Ensures consistent heat distribution, reducing internal stresses and improving material properties. |

| Process Repeatability | Delivers identical results batch after batch, crucial for industrial consistency. |

| Advanced Process Enablement | Supports vacuum brazing, sintering, and high-pressure gas quenching for specialized applications. |

Elevate your industrial heat treatment with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, delivering contaminant-free environments, superior material properties, and unmatched consistency. Don't compromise on quality—contact us today to discuss how our solutions can optimize your processes and drive innovation in your industry!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing