Specifically, vacuum sintering furnaces are ideal for processing materials that are highly reactive with oxygen or those that require exceptional purity and density for their final application. This includes key categories like refractory metals (tungsten, molybdenum), reactive metals (titanium, aluminum), advanced ceramics, and hard alloys (cemented carbides). The vacuum environment is the critical factor that enables the successful processing of these demanding materials.

The decision to use a vacuum sintering furnace is driven by a material's inherent properties. If a material is prone to oxidation at high temperatures or if the final part requires exceptional purity and density, the controlled, oxygen-free environment of a vacuum furnace becomes essential.

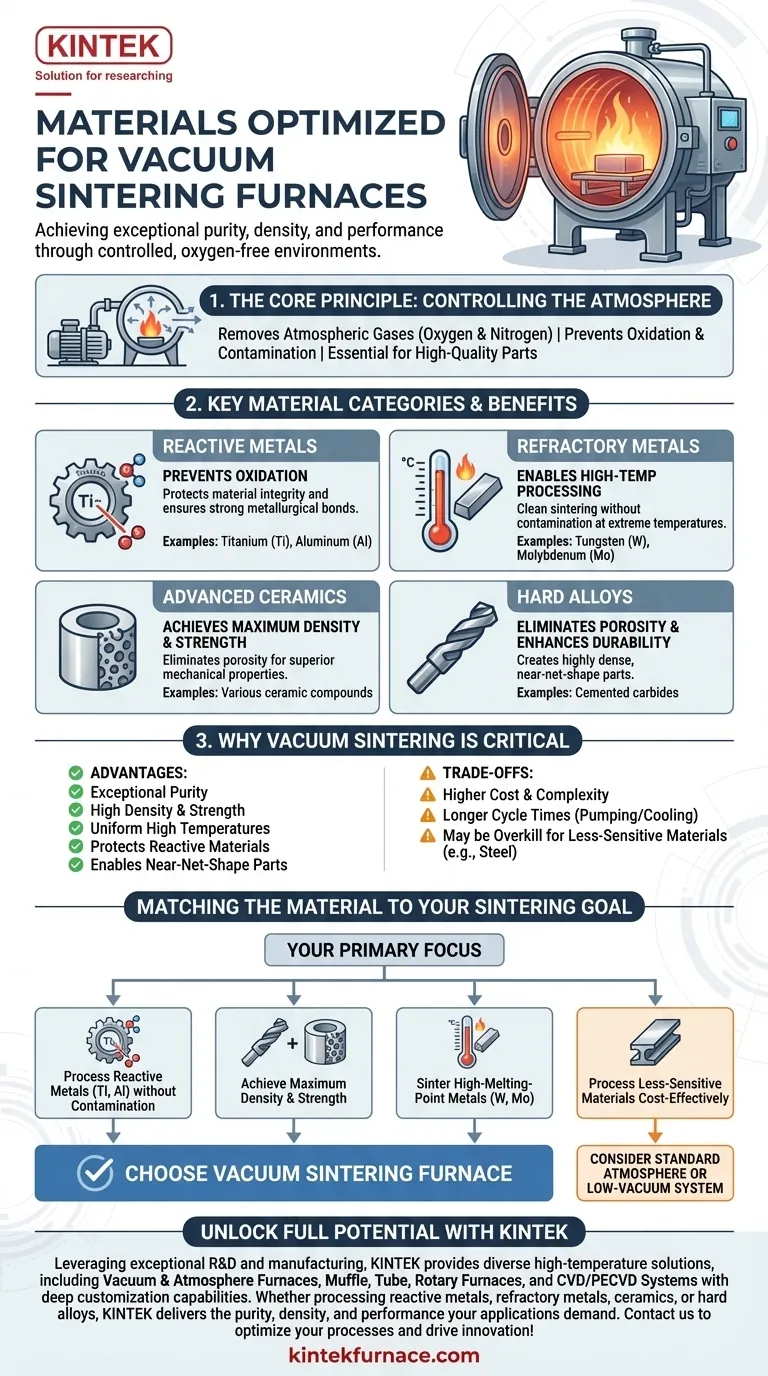

The Core Principle: Controlling the Atmosphere

The primary function of a vacuum furnace is not just to generate heat, but to remove the atmospheric gases—primarily oxygen and nitrogen—that can harm or contaminate materials during the high-temperature sintering process. This control is the reason certain materials are a perfect match for this technology.

Preventing Oxidation in Reactive Materials

Many advanced metals are highly reactive, especially at the elevated temperatures required for sintering.

In a traditional furnace, oxygen would readily form brittle oxide layers on the surface of these materials, preventing proper metallurgical bonding and severely degrading mechanical properties. A vacuum furnace removes the oxygen, creating a clean environment that protects the material's integrity.

Materials like titanium (Ti) and aluminum (Al) are classic examples. Their strong affinity for oxygen makes a vacuum environment non-negotiable for achieving high-quality sintered parts.

Achieving Maximum Purity and Density

Atmospheric gases can become trapped within the structure of a component during sintering, creating voids and porosity.

This porosity acts as a stress concentration point, significantly reducing the strength, durability, and overall performance of the final part. By removing the atmosphere, vacuum sintering allows for the creation of highly dense, near-net-shape parts with minimal internal defects.

This is why the process is critical for high-performance applications using hard alloys and advanced ceramics, where maximum density is directly correlated with material strength.

Enabling High-Temperature Processing

Vacuum is an excellent thermal insulator. This property, combined with advanced heating elements, allows vacuum furnaces to achieve extremely high and uniform temperatures safely and efficiently.

This capability is essential for processing refractory metals like tungsten (W) and molybdenum (Mo), which have exceptionally high melting points. A vacuum ensures they can be sintered cleanly without contamination or oxidation at these extreme temperatures.

Understanding the Trade-offs

While powerful, a vacuum furnace is not always the necessary or most economical choice. Understanding its limitations is key to making an informed decision.

Cost and Complexity

Vacuum furnaces are sophisticated pieces of equipment. They are generally more expensive to purchase, operate, and maintain than conventional atmosphere furnaces due to the need for vacuum pumps, complex control systems, and robust chamber designs.

Cycle Time Considerations

The process of pumping down the chamber to the required vacuum level adds time to the beginning of every cycle. Likewise, cooling can sometimes be slower. For high-volume production of less-sensitive materials, these longer cycle times can impact overall throughput.

When Vacuum is Overkill

For materials that are not sensitive to oxidation, the benefits of a vacuum may not justify the cost. Many common metals, such as steel, can often be processed effectively and more economically in a low-vacuum system or a furnace with a controlled inert gas atmosphere (e.g., nitrogen or argon).

Matching the Material to Your Sintering Goal

Your choice of technology should be guided by the end goal for your component.

- If your primary focus is processing reactive metals like titanium without contamination: The oxygen-free environment of a high vacuum furnace is essential to preserve the material's properties.

- If your primary focus is achieving maximum density and strength in hard alloys or ceramics: Vacuum sintering is the superior choice for eliminating porosity and ensuring part integrity.

- If your primary focus is sintering high-melting-point refractory metals like tungsten: The uniform high-temperature capability and purity of a vacuum furnace are critical for success.

- If your primary focus is processing less-sensitive materials cost-effectively: A standard atmosphere furnace or a simpler low-vacuum system may be a more practical solution.

Ultimately, selecting vacuum sintering is a strategic decision to protect material integrity and achieve performance characteristics that are unattainable in a conventional atmosphere.

Summary Table:

| Material Type | Key Benefits in Vacuum Sintering | Common Examples |

|---|---|---|

| Reactive Metals | Prevents oxidation, ensures material integrity | Titanium, Aluminum |

| Refractory Metals | Enables high-temperature processing without contamination | Tungsten, Molybdenum |

| Advanced Ceramics | Achieves maximum density and strength | Various ceramic compounds |

| Hard Alloys | Eliminates porosity, enhances durability | Cemented carbides |

Unlock the Full Potential of Your Materials with KINTEK's Advanced Vacuum Sintering Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're processing reactive metals, refractory metals, ceramics, or hard alloys, we deliver the purity, density, and performance your applications demand.

Contact us today to discuss how our tailored vacuum sintering furnaces can optimize your processes and drive innovation in your lab!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What role do high-power heating plates play in vacuum contact drying furnaces? Unlock Rapid Thermal Diffusion