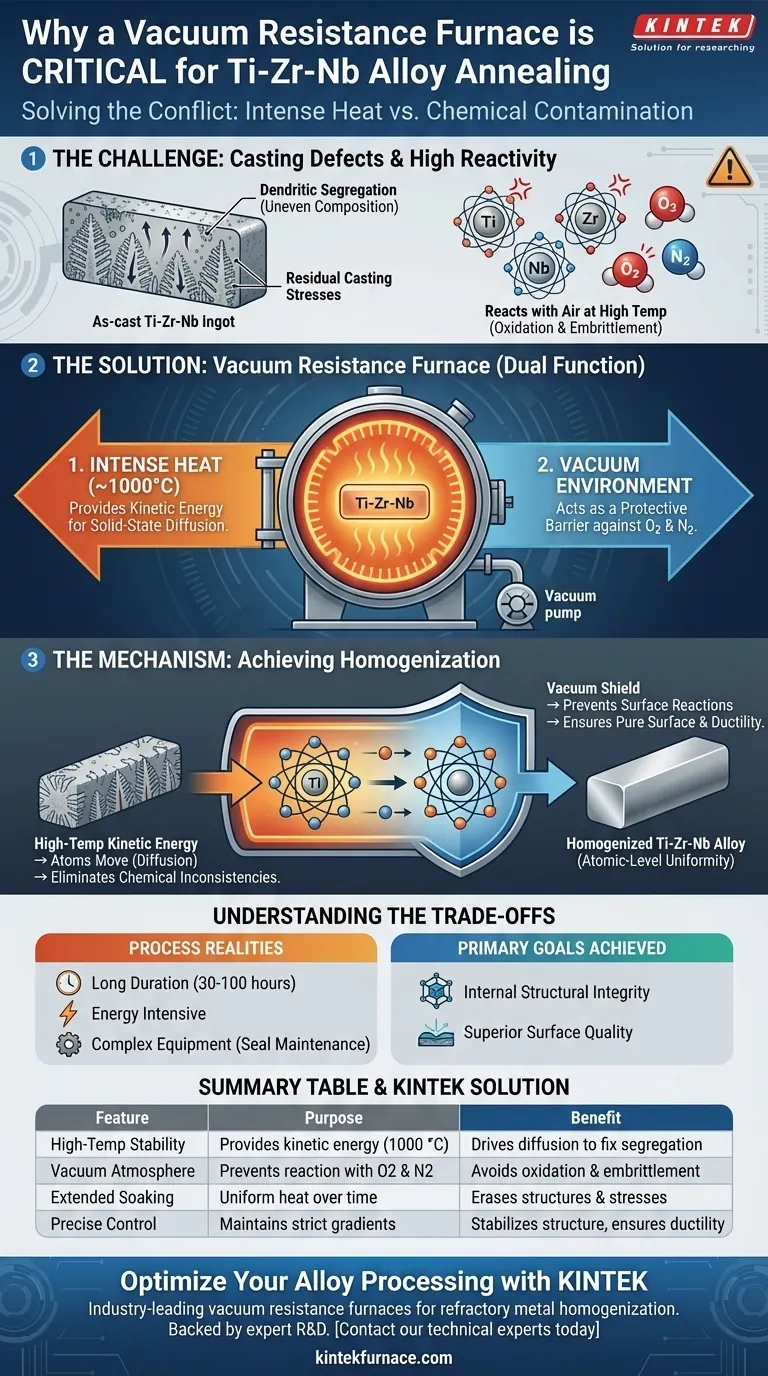

A vacuum resistance furnace is critical for the high-temperature homogenization annealing of Ti-Zr-Nb alloy ingots because it solves two conflicting requirements: applying intense heat while preventing chemical contamination. This equipment provides a stable thermal environment (around 1000 °C) to drive solid-state diffusion and eliminate chemical unevenness, while simultaneously maintaining a vacuum to prevent the highly reactive alloy surface from oxidizing or becoming brittle.

The core function of this furnace is to repair the internal structural defects caused by casting without introducing new surface defects. It uses high-temperature kinetic energy to smooth out chemical segregation, relying on a vacuum to shield the reactive metals from the damaging effects of air.

The Challenge of Casting Ti-Zr-Nb Alloys

The Formation of Dendritic Segregation

During the initial melting and solidification process, alloys do not freeze uniformly. This results in dendritic segregation, where the chemical composition varies significantly between the center of a grain and its boundary.

Residual Casting Stresses

The rapid cooling associated with casting often locks in significant internal mechanical stresses. Without treatment, these residual stresses can lead to deformation or failure during subsequent processing steps.

How the Vacuum Resistance Furnace Solves the Problem

Facilitating Solid-State Diffusion

To eliminate segregation, atoms within the alloy must physically move to achieve a uniform distribution. The furnace provides the precise, constant high temperature (e.g., 1000 °C) needed to give atoms sufficient kinetic energy to diffuse through the solid state.

Eliminating Chemical Inconsistencies

By maintaining this high temperature over a long duration, the furnace ensures the internal chemical composition becomes consistent. This process effectively erases the non-equilibrium structures formed during melting, stabilizing the alloy's phase structure.

Preventing Environmental Reaction

Titanium, zirconium, and niobium are highly reactive refractory metals. If heated to 1000 °C in a standard atmosphere, they would react instantly with oxygen and nitrogen, causing severe oxidation and embrittlement.

Shielding the Surface

The vacuum environment acts as a protective barrier. It allows the alloy to undergo the necessary long-duration heat treatment without reacting with air, ensuring the surface remains pure and the material retains its mechanical integrity.

Understanding the Trade-offs

Process Duration and Energy

Achieving full homogenization is not instant; it often requires extended "soaking" times (potentially 30 to 100 hours) to allow sufficient diffusion. This makes the process energy-intensive and time-consuming compared to simple stress-relief treatments.

Equipment Complexity

Vacuum resistance furnaces are significantly more complex than standard atmospheric furnaces. They require rigorous maintenance of vacuum seals and pumps to ensure the oxygen-free environment is never compromised during the heat cycle.

Making the Right Choice for Your Goal

To determine if your process requires this specific equipment, consider your primary objectives:

- If your primary focus is internal structural integrity: The furnace is required to drive the diffusion necessary to eliminate dendritic segregation and residual casting stresses.

- If your primary focus is surface quality: The vacuum capability is non-negotiable to prevent the oxidation and embrittlement inherent to heating Ti-Zr-Nb alloys in air.

By strictly controlling both temperature and atmosphere, you ensure the alloy achieves atomic-level uniformity while preserving its ductility for future use.

Summary Table:

| Feature | Purpose in Ti-Zr-Nb Annealing | Benefit to Alloy Performance |

|---|---|---|

| High-Temp Stability | Provides kinetic energy (1000 °C) | Drives solid-state diffusion to fix segregation |

| Vacuum Atmosphere | Prevents reaction with O2 and N2 | Avoids surface oxidation and material embrittlement |

| Extended Soaking | Uniform heat over 30-100 hours | Erases dendritic structures and internal stresses |

| Precise Control | Maintains strict thermal gradients | Stabilizes phase structure and ensures ductility |

Optimize Your Alloy Processing with KINTEK

Don't compromise the integrity of your Ti-Zr-Nb alloys with sub-par heating environments. KINTEK provides industry-leading vacuum resistance furnaces designed to handle the rigorous demands of refractory metal homogenization.

Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need standard lab equipment or a fully customized solution for unique high-temperature applications, KINTEK ensures your materials achieve atomic-level uniformity without chemical contamination.

Ready to enhance your material properties? Contact our technical experts today to find the perfect furnace for your laboratory.

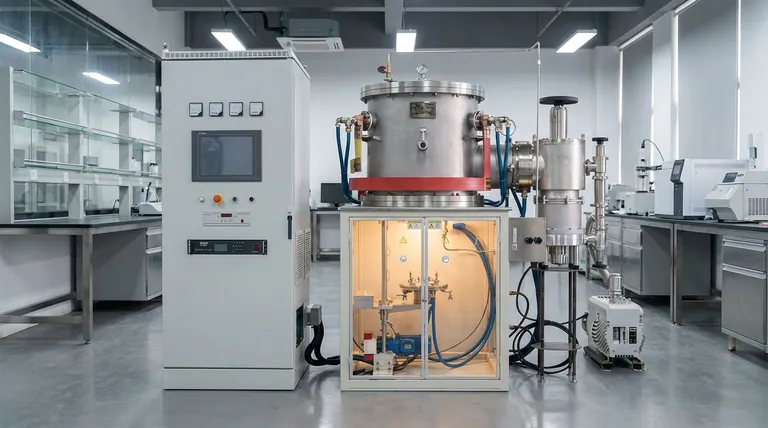

Visual Guide

References

- K. V. Sergienko, A. G. Kolmakov. Physical and Mechanical Properties of Ti-Zr-Nb Alloys for Medical Use. DOI: 10.3390/met14111311

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are the components of a microwave sintering furnace? Boost Efficiency with Advanced Heating Systems

- Why is sealing critical in vacuum or protective atmosphere furnaces? Ensure Quality and Consistency in High-Temp Processing

- How does vacuum heating primarily transfer heat to the workpiece? Unlock Uniform Heat for Superior Results

- How does a circulating water cooling system contribute to the stable operation of high-temp vacuum furnaces? | KINTEK

- What factors should be considered when selecting a vacuum arc furnace? Optimize Your Material Production with Expert Insights

- What advanced control and monitoring features are available in laboratory vacuum furnaces? Enhance Precision and Automation

- What are the benefits of using vacuum heat treating furnaces for metal alloys? Achieve Superior Metal Properties and Performance

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing