At its core, sealing is the single most critical function for ensuring the integrity of any vacuum or protective atmosphere furnace. Its purpose is to create an impenetrable barrier that isolates the internal processing environment from the outside air, which prevents unwanted chemical reactions, maintains process stability, and guarantees the quality of the final material.

The fundamental challenge in high-temperature material processing is controlling chemistry. A furnace seal isn't just a physical barrier; it's the primary defense against atmospheric contamination that can ruin an entire production batch.

The Purpose of a Controlled Atmosphere

To understand why sealing is paramount, you must first understand why these specialized furnaces are used. The entire goal is to heat materials to extreme temperatures without them reacting with the ambient air.

Preventing Oxidation and Contamination

At high temperatures, most metals are highly reactive with oxygen. When ambient air leaks into a furnace, this oxygen immediately reacts with the hot material, a process called oxidation.

This forms oxides on the material's surface, which can degrade its mechanical properties, electrical conductivity, and surface finish. A controlled atmosphere—either a deep vacuum or an inert protective gas like argon or nitrogen—eliminates this oxygen.

Ensuring Process Consistency

A stable and pure atmosphere is essential for repeatable results. Any leakage introduces an uncontrolled variable into the process.

By maintaining perfect atmospheric integrity, you ensure that every batch is processed under the exact same conditions, leading to consistent, predictable, and high-quality outcomes.

How Sealing Failures Undermine the Process

A failure in the sealing system directly negates the entire purpose of using a vacuum or protective atmosphere furnace. The consequences are immediate and often costly.

The Problem of Inward Gas Leakage

In these systems, the pressure inside the furnace is lower than the atmospheric pressure outside. Therefore, any breach in the seal doesn't cause gas to leak out; it causes ambient air to be sucked in.

This inward leakage is the root cause of contamination. Even a microscopic leak can introduce enough oxygen and moisture to compromise the entire process.

Impact on Vacuum Integrity

For a vacuum furnace, the goal is to remove as many air molecules as possible. A leak works directly against the vacuum pump, making it impossible to reach or maintain the required vacuum level.

The system will constantly fight a losing battle, wasting energy and failing to provide the necessary environment for processing.

Contamination of Protective Atmospheres

In a protective atmosphere furnace, a leak pollutes the expensive, high-purity inert gas. Oxygen and nitrogen from the air mix with the argon or other protective gases, rendering them ineffective.

This leads to the same oxidation and contamination issues that the protective atmosphere was meant to prevent in the first place.

Understanding the Trade-offs and Challenges

Achieving and maintaining a perfect seal is a significant engineering challenge, involving complexity and cost that must be managed.

The High Cost of Failure

A compromised seal can lead to the complete loss of an expensive batch of material. The cost of the ruined product, wasted energy, and lost production time often far exceeds the cost of a robust sealing system.

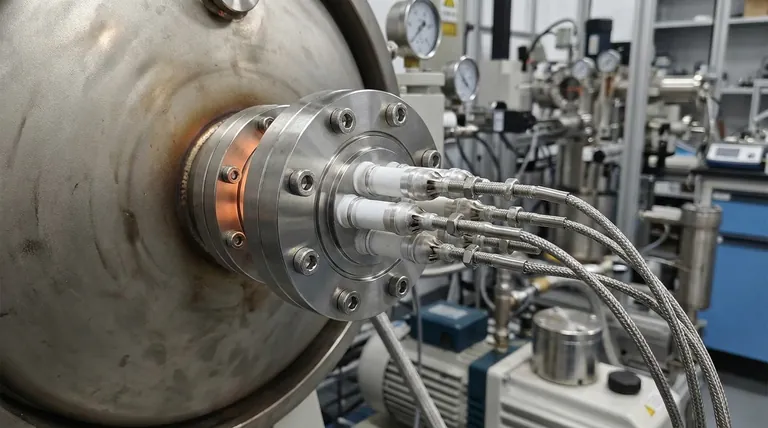

Complexity of Sealing Systems

The seals and gaskets used in these furnaces are not simple rubber rings. They must withstand extreme temperatures, pressure differentials, and repeated thermal cycling.

These high-temperature sealing mechanisms are complex, precision-engineered components that add to the equipment's initial cost and maintenance requirements.

Operational Vigilance is Required

Seals degrade over time and require regular inspection and maintenance. A "set it and forget it" mentality is a recipe for failure. Proper operational protocols and a proactive maintenance schedule are critical for ensuring long-term reliability.

Prioritizing Sealing in Your Operation

Your operational priorities will determine how you approach sealing, but its importance remains constant. A perfect seal is the foundation of any successful high-temperature process.

- If your primary focus is material quality: View the furnace seal as your first and most important line of defense against defects like oxidation and embrittlement.

- If your primary focus is process repeatability: Recognize that sealing integrity is the key to eliminating atmospheric variables and achieving consistent batch-to-batch results.

- If your primary focus is operational efficiency: Implement proactive seal inspection and maintenance to prevent the catastrophic costs of failed batches and unplanned downtime.

Ultimately, a furnace's seal is the gatekeeper of quality, consistency, and profitability.

Summary Table:

| Aspect | Impact of Sealing |

|---|---|

| Prevents Oxidation | Blocks oxygen entry to avoid material degradation |

| Ensures Process Consistency | Maintains stable atmosphere for repeatable outcomes |

| Avoids Contamination | Keeps protective gases pure and vacuum levels intact |

| Reduces Costs | Prevents batch loss and unplanned downtime |

Upgrade your lab's performance with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, enhancing quality, consistency, and efficiency. Contact us today to discuss how we can support your high-temperature processing goals!

Visual Guide

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- Why is a vacuum drying oven necessary before the electrochemical testing of sodium-ion battery electrodes? Optimize SIBs

- What is the primary function of the vacuum pump system in the magnesium powder evaporation process? Ensure High Purity & Efficiency

- Why is a high vacuum pumping system necessary for carbon nanotube peapods? Achieve Precise Molecular Encapsulation

- Why is a laboratory vacuum oven necessary for the processing of Nickel Oxide electrodes? Optimize Solvent Removal

- What are the stages of a vacuum furnace pumping system and how do they function? Learn the Sequential Process for High-Vacuum Efficiency