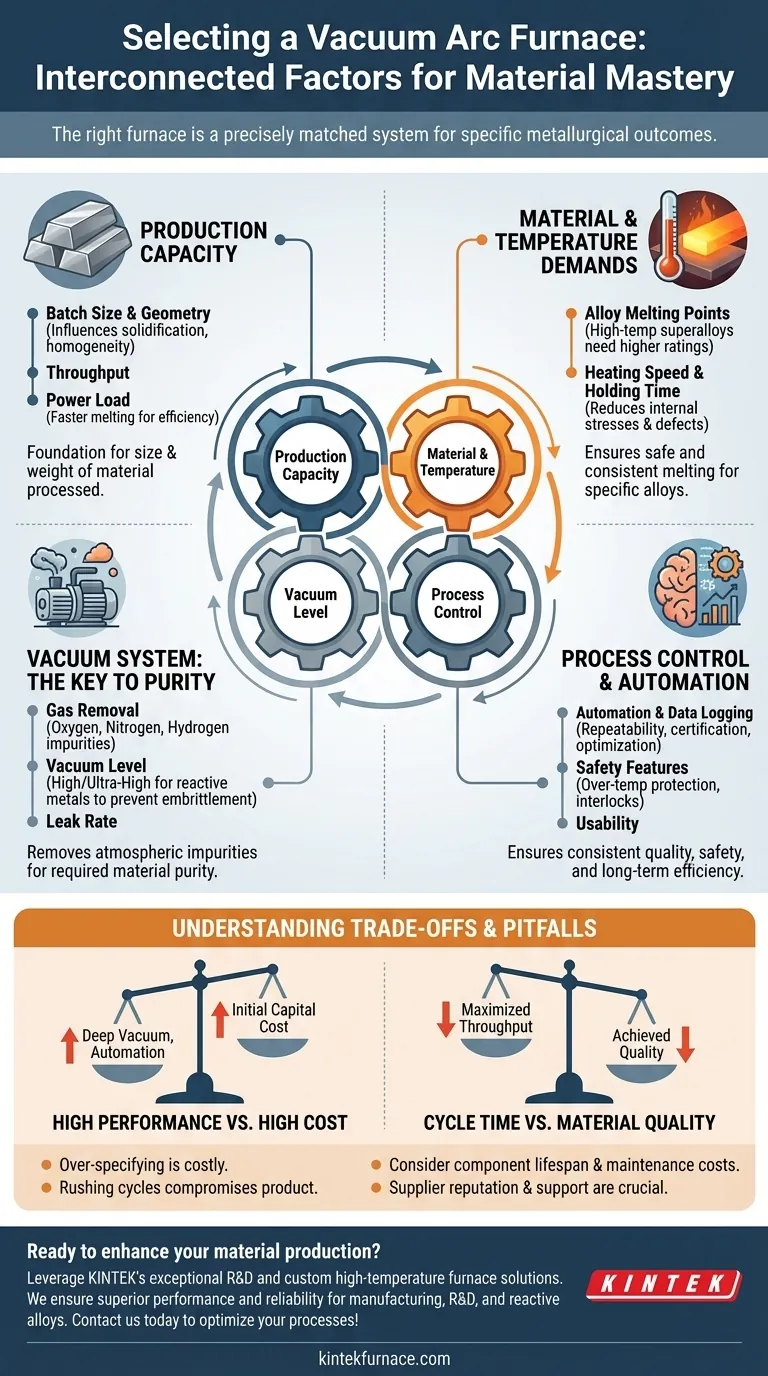

At its core, selecting a vacuum arc furnace requires you to evaluate four primary areas: the production capacity you need, the material and temperature demands of your alloys, the level of vacuum required for material purity, and the degree of process control and automation necessary for consistent quality. These factors are not independent; they form an interconnected system that dictates the final properties of your material.

The most critical mistake is to focus on a single "best" specification. The right vacuum arc furnace is a system where every component—from the power supply to the cooling circuit—is precisely matched to the specific metallurgical outcomes you need to achieve in your final product.

Foundational Production Requirements

Before examining furnace technology, you must first define your production goals. These initial decisions will narrow your options significantly.

Production Capacity: Batch Size and Geometry

The furnace's capacity dictates the size and weight of the material you can process in a single batch, often called an "ingot."

This is not just about throughput. The dimensions of the ingot are critical, as they influence solidification rates and the overall homogeneity of the final material.

Material and Temperature Demands

The furnace must be able to safely and consistently reach the melting point of your target alloys. High-temperature superalloys require a higher maximum operating temperature than standard steels.

Consider the furnace's power load. A higher power rating allows for faster melting, which can be crucial for efficiency and for processing materials that are sensitive to prolonged exposure to heat.

The Core Systems and Their Impact on Quality

A vacuum furnace is an integrated system. Understanding how its core components influence the final product is key to making an informed choice.

The Vacuum System: The Key to Purity

The primary purpose of the vacuum is to remove atmospheric gases like oxygen, nitrogen, and hydrogen, which are considered impurities in many advanced alloys.

The required vacuum level is directly tied to your material goals. Standard applications may only need a low vacuum, while processing reactive metals like titanium or superalloys demands a high or ultra-high vacuum to achieve the necessary purity and prevent embrittlement.

The Heating System: Power and Precision

The arc generation and power supply form the heating system. Its function is to melt the material efficiently and uniformly.

The system's control over heating speed and holding time is crucial. Precise thermal processing reduces internal stresses and defects, leading to superior and more predictable material properties.

The Cooling System: Controlling Microstructure

The cooling phase is just as important as the heating phase. The rate at which the molten material solidifies determines its final grain structure, or microstructure.

An efficient cooling system, often using specific quench gases or water-cooled crucibles, gives you precise control over this process. This control is what allows you to engineer superior mechanical properties like increased tensile strength and fatigue resistance.

Process Control and Operational Factors

Modern furnaces are defined by their intelligence and usability. These factors impact repeatability, safety, and long-term operational costs.

Automation and Data Logging

Digital process control and automation ensure that every batch is produced under identical conditions. This is essential for quality assurance and certification.

Look for systems that allow for detailed data logging of temperature, pressure, and power throughout the cycle. This data is invaluable for process optimization and troubleshooting.

Safety and Usability

Safety features like over-temperature protection and automatic power-off interlocks on the furnace door are non-negotiable for protecting operators.

A well-designed furnace will also be simple to operate, with stable controls and a clear user interface, reducing the chance of human error.

Understanding the Trade-offs and Pitfalls

Selecting a furnace involves balancing competing priorities. Being aware of these trade-offs will help you avoid common purchasing mistakes.

High Performance vs. High Cost

Higher maximum temperatures, deeper vacuum levels, and sophisticated automation systems all increase the initial capital cost of the furnace. Over-specifying a furnace for a simple task is a common and expensive error.

Cycle Time vs. Material Quality

There is often a direct conflict between maximizing throughput and achieving the highest material quality. Rushing the vacuum pump-down, heating, or cooling cycles can introduce defects and compromise the final product.

Component Lifespan and Maintenance

High-performance components, especially heating elements and vacuum pumps, have a finite life and require regular maintenance. Factor the life expectancy and replacement cost of these critical parts into your total cost of ownership calculation.

Supplier Reputation and Support

A furnace is a long-term asset. The supplier's reputation for reliability, technical support, and availability of spare parts is as important as any technical specification.

Making the Right Choice for Your Goal

Your final decision should be guided by your primary application.

- If your primary focus is high-volume production of standard alloys: Prioritize furnace capacity, robust automation for repeatability, and energy efficiency to manage operational costs.

- If your primary focus is research and development (R&D): Prioritize flexibility, precise process control with extensive data logging, and a wide operating window for temperature and pressure.

- If your primary focus is producing high-purity, reactive, or superalloys: The vacuum system's ultimate pressure and leak rate are your most critical factors, followed by precise cooling control to define microstructure.

Ultimately, a well-chosen vacuum arc furnace is an investment in repeatable quality and absolute control over your material's final properties.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Production Capacity | Batch size, ingot geometry, throughput |

| Material and Temperature | Alloy melting points, power load, heating speed |

| Vacuum System | Vacuum level for purity, leak rate, gas removal |

| Heating System | Arc generation, power supply, thermal control |

| Cooling System | Quench gases, solidification rates, microstructure |

| Process Control | Automation, data logging, repeatability |

| Operational Factors | Safety features, usability, maintenance |

| Trade-offs | Cost vs. performance, cycle time vs. quality |

Ready to enhance your material production with a tailored vacuum arc furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental and production needs. Whether you're in high-volume manufacturing, R&D, or processing reactive alloys, we ensure superior performance and reliability. Contact us today to discuss how we can optimize your processes and achieve consistent, high-quality results!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys