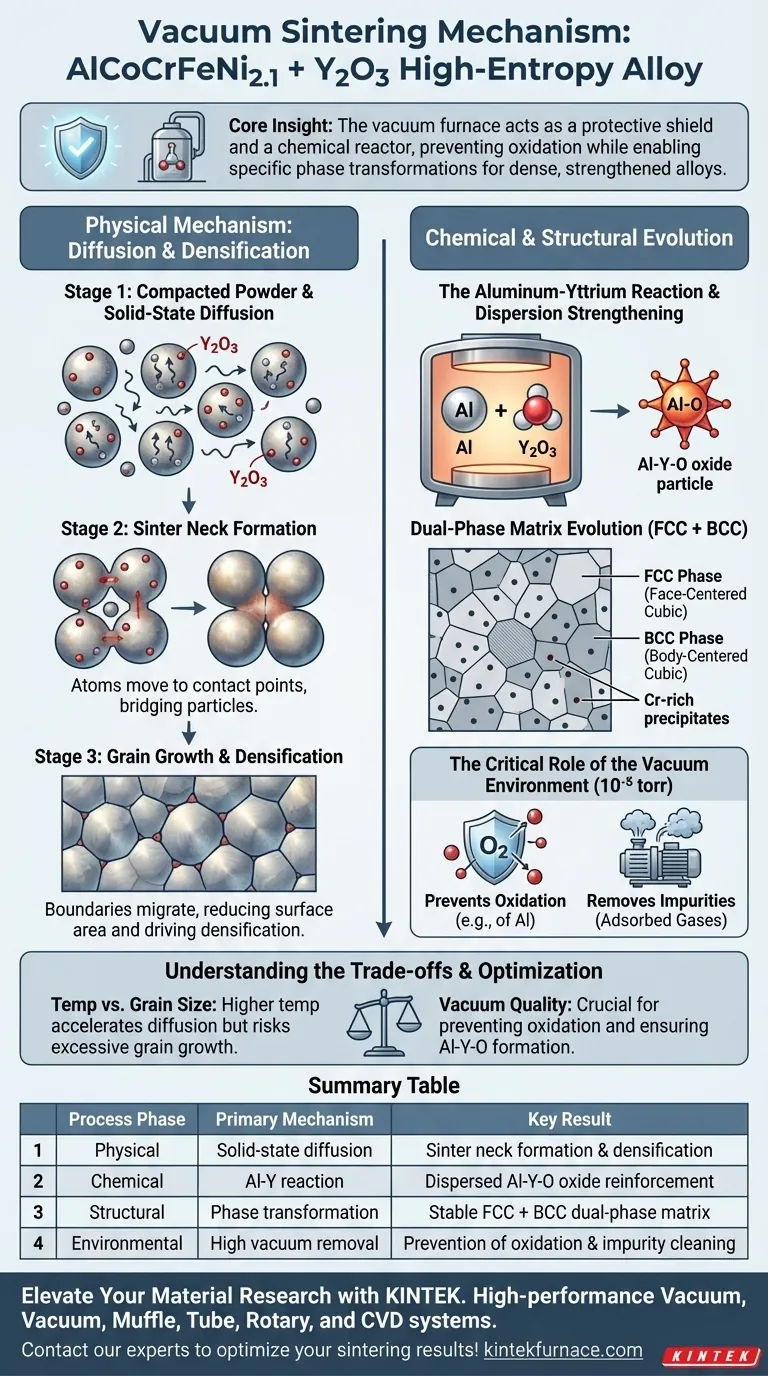

The primary mechanism driving the vacuum sintering of AlCoCrFeNi2.1 and Y2O3 composites is solid-state diffusion. This thermal process facilitates the movement of atoms across particle boundaries, resulting in the formation of sinter necks and the subsequent growth of grains within the compacted powder. Specifically, the vacuum environment promotes a critical atomic interaction between aluminum and yttrium oxide, generating dispersed Al-Y-O oxides that reinforce the material.

Core Insight: The vacuum furnace acts as both a protective shield and a chemical reactor. It prevents the oxidation of reactive elements like aluminum while simultaneously enabling the specific phase transformations required to turn loose powder into a dense, dispersion-strengthened high-entropy alloy.

The Physical Mechanism: Diffusion and Densification

Solid-State Diffusion

The fundamental engine of this process is solid-state diffusion. At high temperatures, atoms within the compacted powder gain enough energy to move through the crystal lattice without melting the material.

Sinter Neck Formation

As diffusion accelerates, material moves to the contact points between powder particles. This accumulation forms sinter necks, effectively bridging separate particles and initiating the bonding process.

Grain Growth

Following neck formation, the boundaries between particles migrate. This leads to grain growth, which reduces the total surface area and internal energy of the system, driving the densification of the bulk material.

Chemical Interactions and Phase Control

The Aluminum-Yttrium Reaction

A unique mechanism in this specific alloy system is the interaction between aluminum (from the matrix) and yttrium oxide (Y2O3). The furnace environment promotes atomic interaction that converts these components into complex Al-Y-O oxides.

Dispersion Strengthening

These newly formed Al-Y-O oxides are not defects; they are intentional reinforcements. The thermal processing determines the morphology and distribution of these phases, which are critical for refining the grain structure and enhancing the strength of the final matrix.

Dual-Phase Matrix Evolution

Beyond the oxides, the vacuum treatment governs the matrix structure itself. It allows the AlCoCrFeNi2.1 alloy to evolve into a stable Face-Centered Cubic (FCC) and Body-Centered Cubic (BCC) dual-phase structure, often accompanied by chromium-rich precipitates.

The Critical Role of the Vacuum Environment

Prevention of Oxidation

The vacuum (often as low as 10^-5 torr) is essential for chemical stability. It prevents the severe oxidation of the metallic elements—particularly aluminum—which creates brittle defects and inhibits bonding.

Removal of Impurities

The low-pressure environment actively removes adsorbed gases and volatile impurities from the surface of the powder particles. Cleaning the particle surfaces in situ ensures that the grain boundaries bond directly, rather than being separated by contaminant layers.

Understanding the Trade-offs

Temperature vs. Grain Size

While higher temperatures accelerate diffusion and densification, they also promote excessive grain growth. Unchecked grain growth can counteract the benefits of the dispersion strengthening, potentially lowering the material's yield strength.

Vacuum Quality Sensitivity

The process is highly sensitive to the quality of the vacuum. Even minor leaks or insufficient vacuum levels can lead to the oxidation of aluminum, preventing the formation of the desired Al-Y-O phases and compromising the mechanical integrity of the bulk material.

Making the Right Choice for Your Goal

To optimize the processing of AlCoCrFeNi2.1 with Y2O3, consider your specific mechanical requirements:

- If your primary focus is maximum density: Prioritize a sintering cycle that maximizes time at peak temperature to ensure complete solid-state diffusion and pore elimination.

- If your primary focus is strength and refinement: strictly control the peak temperature to facilitate Al-Y-O formation without allowing the matrix grains to coarsen excessively.

The success of vacuum sintering lies in balancing the physical force of diffusion with the chemical delicacy of oxide formation.

Summary Table:

| Process Phase | Primary Mechanism | Key Result |

|---|---|---|

| Physical | Solid-state diffusion | Sinter neck formation & densification |

| Chemical | Al-Y reaction | Dispersed Al-Y-O oxide reinforcement |

| Structural | Phase transformation | Stable FCC + BCC dual-phase matrix |

| Environmental | High vacuum removal | Prevention of oxidation & impurity cleaning |

Elevate Your Material Research with KINTEK

Unlock the full potential of your high-entropy alloys and advanced composites. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum, Muffle, Tube, Rotary, and CVD systems designed for precision material processing.

Whether you are refining grain structures or engineering dispersion-strengthened matrices, our lab furnaces are fully customizable to meet your unique thermal needs.

Ready to optimize your sintering results? Contact our technical experts today to find your perfect furnace solution!

Visual Guide

References

- Chun‐Liang Chen, Fang-Yu Huang. Investigations of Oxide Dispersoids and Annealing on Characteristics of AlCoCrFeNi2.1 Coatings and Bulks Prepared by Mechanical Alloying. DOI: 10.3390/coatings14040442

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why are vacuum ovens and argon gas protection necessary for MXene monoliths? Ensure Density and Chemical Integrity

- What happens during the heating phase of a vacuum furnace? Master Radiative Heat and Outgassing Control

- What is the objective of vacuum drying in NaF–Na3AlF6 electrolytes? Ensure High-Purity Molten Salt Performance

- What industries benefit from vacuum heat treatment? Boost Performance in Aerospace, Automotive, and Medical

- Why is sealing critical in vacuum or protective atmosphere furnaces? Ensure Quality and Consistency in High-Temp Processing

- What is the mechanism and effect of post-annealing NiTi thin films in a vacuum furnace? Unlock Superelasticity

- How do laboratory high-temperature furnaces achieve microstructure control in Ti-Nb-Zr alloys? Key Precision Techniques

- What is the purpose of the internal circulation pure water cooling system in vacuum sintering furnaces? Ensure Reliable Heat Management for High-Temperature Sintering