Fundamentally, industries that demand metallic components with pristine surfaces and exceptionally uniform mechanical properties rely on vacuum heat treatment. The most prominent examples are aerospace, automotive, and healthcare, where material failure is not an option and performance must be predictable and absolute. This process is chosen when conventional heat treatment in air would introduce unacceptable levels of contamination, such as oxides, that compromise the integrity of the final part.

The core value of vacuum heat treatment is not merely heating a material, but doing so within an ultra-clean environment. By removing air and other contaminants, the process prevents unwanted chemical reactions, ensuring the material achieves its highest potential purity, strength, and surface quality.

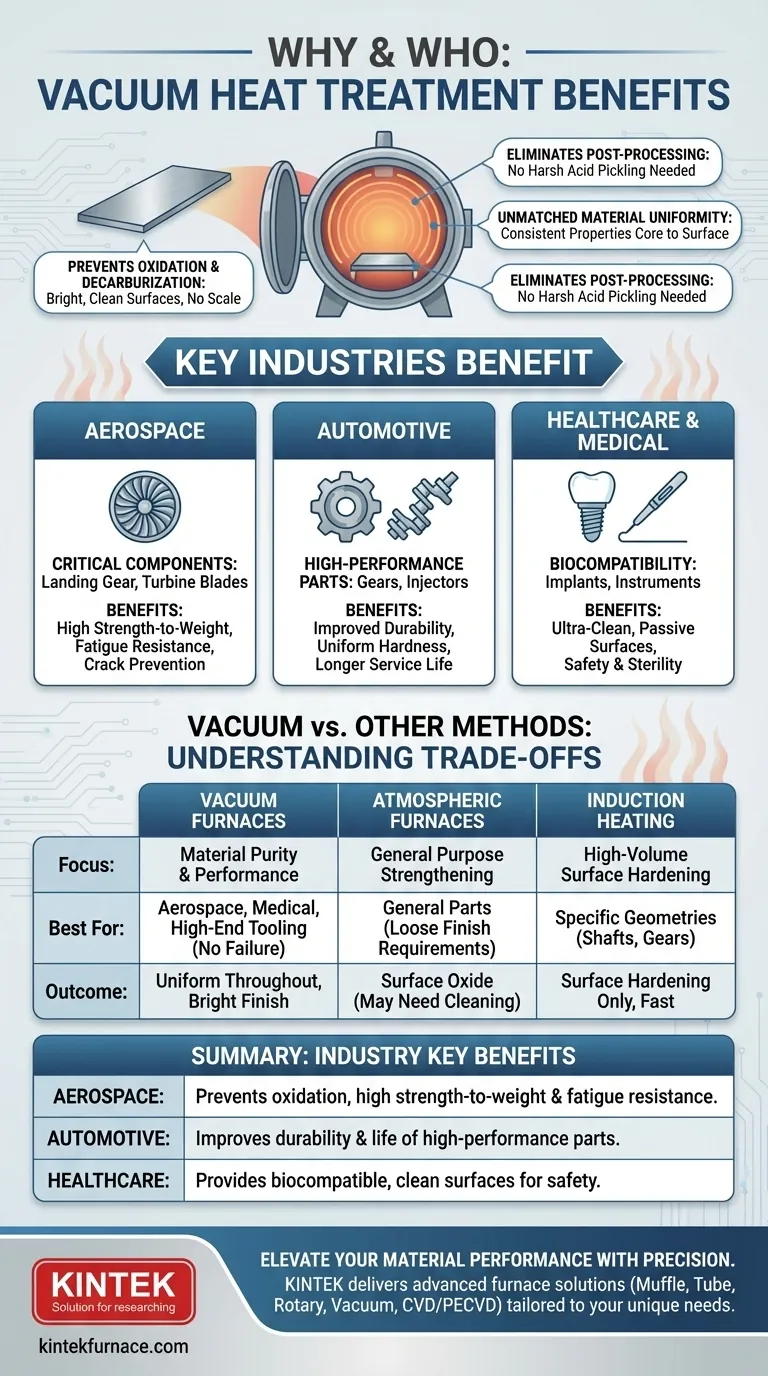

The Core Principle: Why a Vacuum Changes Everything

Heat treatment modifies a material's internal structure to improve its properties. Performing this in a vacuum furnace elevates the process from a simple hardening or softening operation to a precision engineering tool.

Preventing Oxidation and Decarburization

When metals are heated in the presence of oxygen, they form a layer of oxide scale on the surface. This not only ruins the surface finish but can also alter the dimensions of a precision part. A vacuum environment, by definition, removes the oxygen, completely preventing this reaction and resulting in a "bright" finish that requires no subsequent cleaning.

Achieving Unmatched Material Uniformity

A vacuum furnace allows for extremely precise control over both heating and cooling rates. This ensures the entire component, from its surface to its core, experiences a uniform thermal cycle. The result is a more consistent grain structure, leading to predictable and repeatable mechanical properties like hardness, strength, and toughness across the entire part.

Eliminating Post-Processing Steps

For materials like brass or certain stainless steels, traditional heat treatment necessitates a secondary "pickling" process using harsh acids to remove the oxide scale. Vacuum heat treatment produces a clean, bright part directly from the furnace, eliminating this costly, time-consuming, and environmentally harmful step.

A Closer Look at Key Industries

The benefits of vacuum heat treatment are not theoretical; they are critical to the function of components in the world's most demanding sectors.

Aerospace

In aerospace, components must have the highest possible strength-to-weight ratio and fatigue resistance. Surface or subsurface imperfections introduced by oxidation can become crack initiation sites, leading to catastrophic failure. Vacuum treatment is essential for critical parts like landing gear components, turbine blades, and structural fasteners to ensure they are free of such defects.

Automotive

While not all automotive parts require this level of precision, high-performance components do. Gears, crankshafts, and fuel injector components are subjected to immense stress and wear. The uniform hardness and clean surfaces provided by vacuum heat treatment directly translate to improved durability, longer service life, and greater reliability.

Healthcare & Medical Devices

Biocompatibility is the primary concern for medical implants, such as artificial joints or dental posts, as well as surgical instruments. An oxide layer can provoke an adverse reaction from the body or compromise sterility. Vacuum heat treatment provides an immaculately clean, passive surface that is essential for safe and effective medical devices.

Understanding the Trade-offs

Vacuum heat treatment is a superior process, but it is not the only solution. Understanding its place among other methods is key to making an informed decision.

Vacuum vs. Atmospheric Furnaces

Standard atmospheric furnaces are simpler and often more cost-effective for general-purpose treatments where a layer of oxide scale is acceptable or will be machined off later. Vacuum furnaces are the specified choice when surface integrity, cleanliness, and the prevention of chemical reactions are paramount.

Vacuum vs. Induction Heating

Induction heating is extremely fast, energy-efficient, and well-suited for automating the surface hardening of specific part geometries, like shafts and gears. However, it is primarily a surface treatment. Vacuum treatment is better suited for processing complex shapes or batches of parts, ensuring uniform properties throughout the entire material, not just at the surface.

Making the Right Choice for Your Goal

Selecting the correct thermal process depends entirely on the component's end-use requirements and budget constraints.

- If your primary focus is maximum material purity and performance: Vacuum heat treatment is the definitive choice for applications in aerospace, medical, or high-end tooling where failure is not an option.

- If your primary focus is high-volume surface hardening: Induction heating offers unparalleled speed and efficiency for specific geometries where only the surface properties need to be altered.

- If your primary focus is general-purpose strengthening with loose surface finish requirements: A standard atmospheric furnace is often the most cost-effective and practical solution.

Ultimately, choosing the right heat treatment method is about aligning the process capabilities with your engineering and commercial objectives.

Summary Table:

| Industry | Key Benefits |

|---|---|

| Aerospace | Prevents oxidation, ensures high strength-to-weight ratio and fatigue resistance for critical components like turbine blades. |

| Automotive | Improves durability and service life of high-performance parts such as gears and crankshafts with uniform hardness. |

| Healthcare | Provides biocompatible, clean surfaces for medical implants and instruments, essential for safety and sterility. |

Ready to elevate your material performance with precision heat treatment? At KINTEK, we leverage exceptional R&D and in-house manufacturing to deliver advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Whether you're in aerospace, automotive, or healthcare, we can help you achieve superior purity, strength, and efficiency. Contact us today to discuss how our solutions can benefit your industry!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance