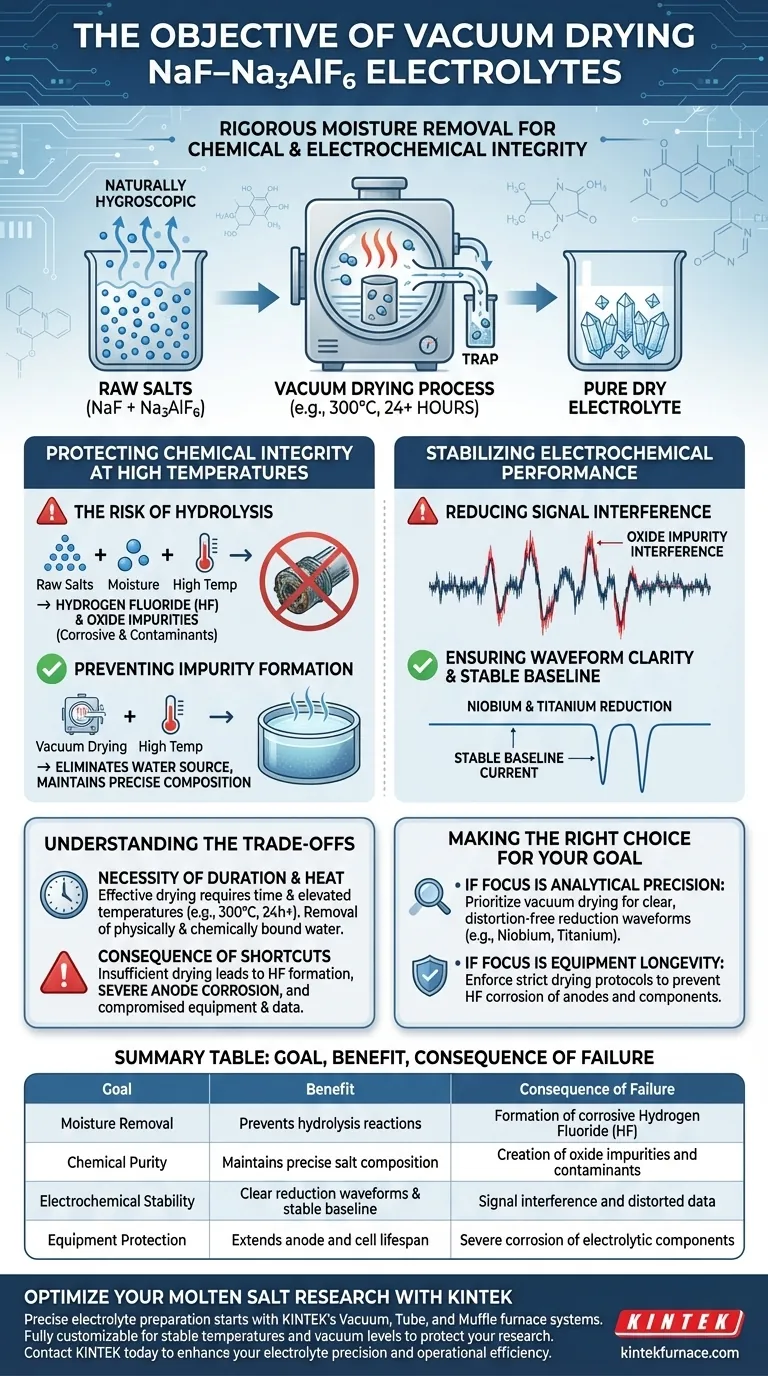

The primary objective of vacuum drying NaF–Na3AlF6 electrolytes is the rigorous removal of trace moisture adsorbed within the raw salts. Because these fluoride salts are naturally hygroscopic, this pre-treatment step is critical to prevent chemical degradation before the materials are introduced to high-temperature environments.

Core Takeaway Fluoride salts react aggressively with water at high temperatures to form corrosive hydrogen fluoride and oxide impurities. Vacuum drying ensures the chemical integrity of the molten salt, preventing electrolyte deterioration and minimizing interference during electrochemical reduction processes.

Protecting Chemical Integrity at High Temperatures

The Risk of Hydrolysis

Raw salts, specifically NaF and Na3AlF6, easily absorb moisture from the surrounding environment. If this moisture is not removed prior to heating, the salts undergo hydrolysis reactions.

Preventing Impurity Formation

When water interacts with fluoride salts at high temperatures, it produces hydrogen fluoride (HF) and various oxide impurities. Vacuum drying eliminates the water source effectively, thereby preventing the formation of these byproducts and maintaining the precise chemical composition of the molten salt.

Stabilizing Electrochemical Performance

Reducing Signal Interference

The presence of moisture-induced oxide impurities acts as a contaminant in the electrolyte. These impurities create interference ions that disrupt the electrochemical data.

Ensuring Waveform Clarity

Specifically in the reduction of metals like niobium and titanium, impurities can distort the reduction waveforms. By removing moisture, the vacuum drying process ensures these waveforms remain clear and interpretable.

Establishing a Stable Baseline

A clean electrolyte results in a stable baseline current. This stability is essential for accurate process monitoring and efficient metal deposition, ensuring that the current applied drives the intended reaction rather than side reactions with impurities.

Understanding the Trade-offs

The Necessity of Duration and Heat

Effective drying is not instantaneous. It often requires processing materials at elevated temperatures (e.g., 300°C) for extended periods (often 24 hours or more) to ensure the removal of both physically adsorbed water and chemically bound crystalline water.

The Consequence of Shortcuts

Insufficient drying leads to immediate consequences in the molten state. Beyond poor electrochemical performance, residual moisture leads to the formation of HF, which causes severe anode corrosion. Skipping or shortening this step compromises both the data quality and the lifespan of the electrolytic cell equipment.

Making the Right Choice for Your Goal

To optimize your electrolyte preparation based on your specific requirements:

- If your primary focus is analytical precision: Prioritize vacuum drying to eliminate oxide interference, ensuring the reduction waveforms for metals like niobium and titanium are free from distortion.

- If your primary focus is equipment longevity: Enforce strict drying protocols to prevent hydrolysis, thereby stopping the formation of corrosive hydrogen fluoride that attacks anodes and cell components.

The vacuum drying stage is not merely a preparatory step; it is the fundamental control point for ensuring the chemical stability and electrochemical precision of the entire molten salt system.

Summary Table:

| Goal | Benefit | Consequence of Failure |

|---|---|---|

| Moisture Removal | Prevents hydrolysis reactions | Formation of corrosive Hydrogen Fluoride (HF) |

| Chemical Purity | Maintains precise salt composition | Creation of oxide impurities and contaminants |

| Electrochemical Stability | Clear reduction waveforms & stable baseline | Signal interference and distorted data |

| Equipment Protection | Extends anode and cell lifespan | Severe corrosion of electrolytic components |

Optimize Your Molten Salt Research with KINTEK

Precise electrolyte preparation starts with high-performance thermal processing. KINTEK provides industry-leading Vacuum, Tube, and Muffle furnace systems specifically designed to meet the rigorous demands of fluoride salt drying and material synthesis.

Backed by expert R&D and precision manufacturing, our systems are fully customizable to ensure stable temperatures and vacuum levels, protecting your research from impurities and equipment corrosion.

Ready to elevate your laboratory standards? Contact KINTEK today to discover how our high-temperature solutions can enhance your electrolyte precision and operational efficiency.

Visual Guide

References

- Bo Zhang, Maofa Jiang. Electrochemical Behavior of Niobium Oxide and Titanium Oxide in NaF–Na3AlF6 Molten Salt. DOI: 10.3390/met14030297

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What processes are performed in a high-temperature vacuum furnace? Achieve Purity and Precision in Material Processing

- What temperature range can a vacuum furnace achieve? Unlock Extreme Heat for Your Lab

- What is the purpose of an annealing furnace in the mechanical industry? Boost Metal Performance and Efficiency

- Can you braze in a vacuum? Achieve Unmatched Joint Cleanliness and Strength

- How does graphite's thermal conductivity improve vacuum furnace performance? Achieve Superior Thermal Uniformity

- What are the specific requirements for the drying process in a vacuum drying oven? Essential MXene-ZrB2 Prep Steps

- Why is an industrial-grade high-temperature sintering furnace required for the production of multi-channel ceramic membrane supports? Key Roles in Material Transformation

- How are vacuum furnaces classified based on temperature? Find the Right Furnace for Your Heat Treatment Needs