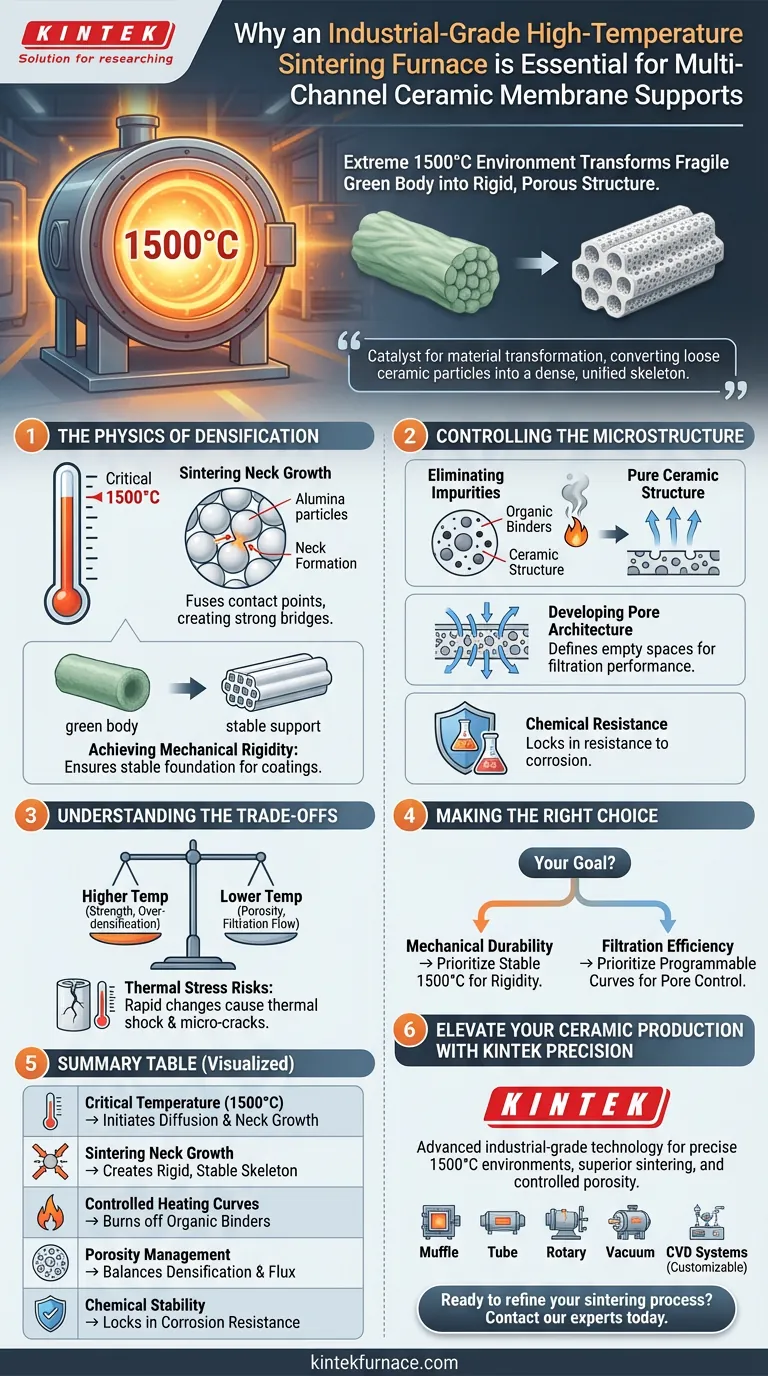

An industrial-grade high-temperature sintering furnace is required primarily to generate the extreme 1500°C thermal environment necessary to process alumina-based ceramic supports. This specific temperature threshold triggers the physicochemical changes that transform a fragile, extruded "green body" into a rigid, porous structure with the mechanical strength needed for industrial filtration.

The furnace serves as the catalyst for material transformation, converting loose ceramic particles into a dense, unified skeleton through sintering neck growth. This process is the decisive factor in establishing the final strength, chemical resistance, and pore structure of the membrane support.

The Physics of Densification

Reaching Critical Temperatures

Production of robust multi-channel supports, particularly those made of alumina, requires temperatures reaching 1500°C.

Standard kilns cannot maintain this intensity, which is essential for initiating the diffusion of ceramic particles.

Sintering Neck Growth

At these elevated temperatures, individual alumina particles undergo a process called sintering neck growth.

This is where the contact points between particles fuse together, creating strong bridges that solidify the material without melting it completely.

Achieving Mechanical Rigidity

The transition from a "green body" (the unfired shape) to a finished support relies on this thermal densification.

The furnace ensures the support becomes a stable foundation, strong enough to withstand the application of subsequent functional layer coatings without collapsing or degrading.

Controlling the Microstructure

Eliminating Impurities

Before the ceramic particles fuse, the furnace must remove non-ceramic components.

Precise heating curves utilize specific holding times to burn off organic binders and residual impurities used during the extrusion phase, leaving behind a pure ceramic structure.

Developing Pore Architecture

The firing process does not just harden the material; it defines the empty spaces within it.

The thermal cycle facilitates the specific arrangement of particles, forming a porous ceramic membrane substrate with a controlled porosity essential for filtration performance.

Chemical Resistance

By facilitating complete physicochemical bonding and crystal transformation, the furnace locks in the material's chemical properties.

This ensures the final membrane can resist corrosion and chemical attack during harsh industrial filtration processes.

Understanding the Trade-offs

Temperature vs. Porosity

There is a delicate balance between firing temperature and filtration capability.

Higher temperatures generally increase mechanical strength but can lead to over-densification, which closes off the pores and reduces the membrane's flux (flow rate).

Thermal Stress Risks

While high heat is necessary, rapid temperature changes can be destructive.

Industrial furnaces must provide precise control over heating and cooling rates; otherwise, the ceramic supports may suffer from thermal shock, leading to micro-cracks that ruin the integrity of the multi-channel structure.

Making the Right Choice for Your Goal

To select the correct sintering protocol for your ceramic supports, consider your specific performance requirements:

- If your primary focus is mechanical durability: Prioritize a furnace capable of sustaining stable 1500°C temperatures to maximize sintering neck growth and support rigidity.

- If your primary focus is filtration efficiency: Ensure the furnace offers programmable heating curves to precisely control binder removal and pore formation without over-densifying the substrate.

The furnace is not merely a heat source; it is the precision tool that defines the structural reality of the final ceramic product.

Summary Table:

| Feature | Impact on Ceramic Membrane Support |

|---|---|

| Critical Temperature (1500°C) | Initiates alumina particle diffusion and sintering neck growth. |

| Sintering Neck Growth | Fuses particles at contact points to create a rigid, stable skeleton. |

| Controlled Heating Curves | Effectively burns off organic binders to ensure material purity. |

| Porosity Management | Balances densification and flux by defining the internal pore structure. |

| Chemical Stability | Locks in resistance to corrosion for use in harsh industrial environments. |

Elevate Your Ceramic Production with KINTEK Precision

Don't let inconsistent thermal cycles compromise the integrity of your multi-channel ceramic supports. KINTEK provides the advanced industrial-grade technology needed to achieve the precise 1500°C environment required for superior sintering neck growth and controlled porosity.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to your specific lab or industrial high-temp furnace needs. Whether you are optimizing mechanical durability or filtration efficiency, our systems deliver the thermal accuracy your project demands.

Ready to refine your sintering process? Contact our experts today to find the perfect customizable solution for your unique high-temperature applications.

Visual Guide

References

- Comparative Carbon Footprint Analysis of Alumina-Based Multichannel and Hollow Fiber Ceramic Membranes for Microfiltration. DOI: 10.3390/separations12080220

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What key technologies are used in the development of multi-chamber continuous vacuum furnaces? Boost Throughput with Advanced Automation

- Which industries commonly use vacuum arc furnaces and why? Unlock Ultra-Pure Metals for Aerospace, Medical, and Energy

- What is the purpose of using a laboratory vacuum drying oven for post-processing lignin nanofiber membranes?

- What are the key advantages of using a vacuum sintering furnace? Achieve High-Purity, Dense Materials with Superior Control

- What is the maximum working temperature of high temperature vacuum furnaces? Unlock Precision Heating Up to 2600°C

- What role does a vacuum furnace play in the reduction of GO to rGO? Optimize Your High-Purity Graphene Composites

- What are the disadvantages of using a vacuum furnace? High Costs, Material Limits, and More

- What are the two main types of vacuum furnace chillers? Choose the Best for Your Lab's Efficiency