In short, the two principal types of vacuum furnace chillers are air-cooled and water-cooled. An air-cooled chiller uses ambient air and fans to dissipate heat, while a water-cooled chiller uses a secondary water source, typically a cooling tower, to achieve the same goal. The choice between them depends entirely on your facility's infrastructure, climate, and operational budget.

The core decision is not simply about air versus water. It's a strategic trade-off between the lower initial cost and simplicity of an air-cooled system versus the superior long-term efficiency and performance stability of a water-cooled system.

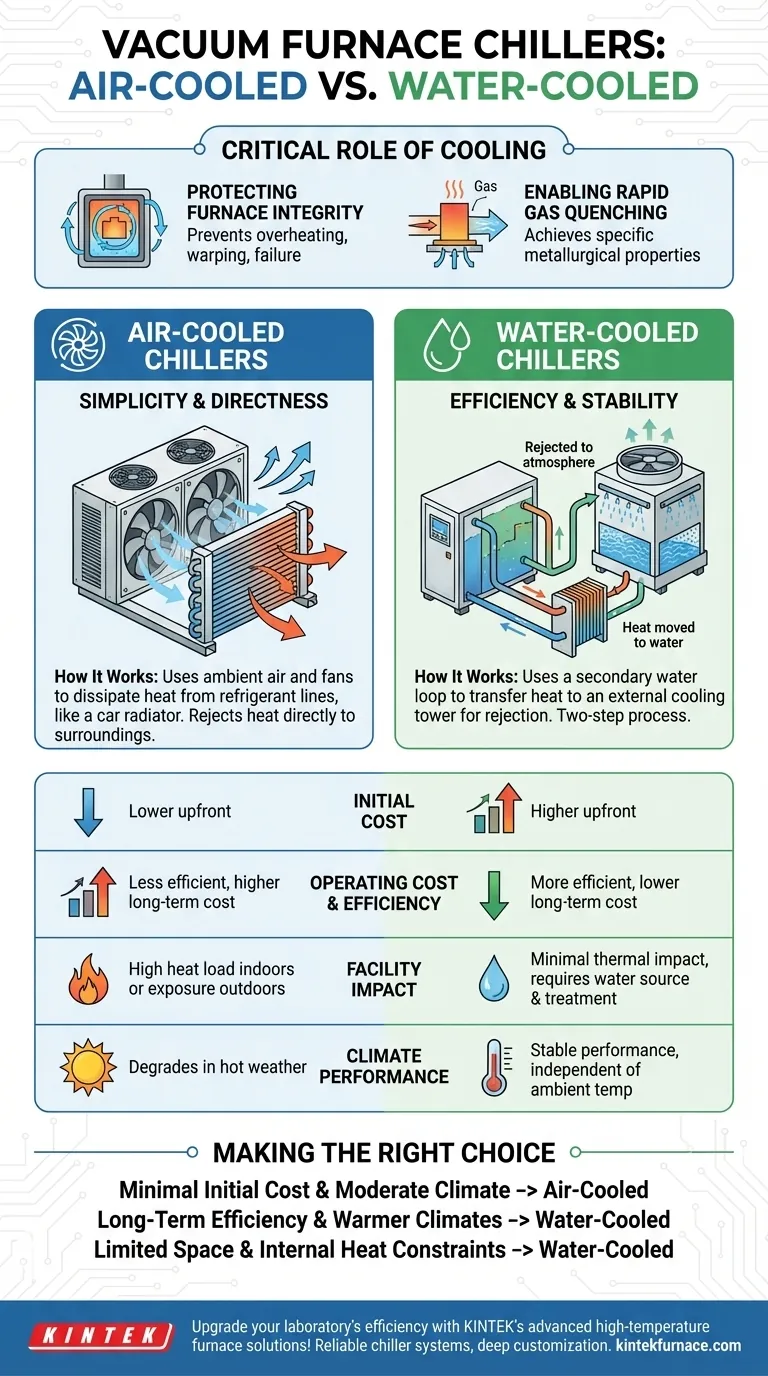

The Critical Role of Cooling in a Vacuum Furnace

Before comparing chiller types, it's essential to understand why cooling is non-negotiable for a vacuum furnace. The chiller is not an optional accessory; it's a mission-critical component with two primary responsibilities.

Protecting Furnace Integrity

The intense heat generated inside a vacuum furnace must be contained. A chiller continuously circulates coolant through the furnace's double-walled body, door, seals, and power feedthroughs.

This process prevents the furnace structure from overheating, warping, or failing, ensuring operational safety and longevity. Without constant cooling, the furnace would destroy itself.

Enabling Rapid Gas Quenching

Many heat-treating processes require the part to be cooled rapidly—or "quenched"—to achieve specific metallurgical properties.

This is done by flooding the hot zone with an inert gas like nitrogen or argon. This gas absorbs heat from the part and is then circulated through a heat exchanger cooled by the chiller. This allows for precise, repeatable control over the material's final characteristics.

A Closer Look at Each Chiller Type

The fundamental difference between the two chiller types is how they reject the heat they have removed from the furnace.

Air-Cooled Chillers: Simplicity and Directness

An air-cooled chiller works like the radiator in your car. It uses a series of coils and high-volume fans to blow ambient air across the refrigerant lines, transferring the heat directly into the surrounding atmosphere.

These systems are self-contained and are often simpler and less expensive to install initially. They require no additional water sources or cooling towers.

Water-Cooled Chillers: Efficiency and Stability

A water-cooled chiller uses a secondary water loop to remove heat. Heat from the refrigerant is transferred to this water, which is then pumped to an external cooling tower where the heat is finally rejected into the atmosphere.

This two-step process makes the system more complex but also significantly more efficient and stable, as its performance is not directly tied to the ambient air temperature.

Understanding the Trade-offs

Choosing the right chiller involves a careful analysis of costs, facility limitations, and climate.

Initial Cost vs. Operating Cost

An air-cooled chiller typically has a lower upfront purchase and installation cost.

However, a water-cooled chiller is more energy-efficient. For larger furnaces or continuous operations, the lower electricity consumption can lead to significant long-term savings that outweigh the higher initial investment.

Facility and Environmental Impact

Air-cooled chillers, if installed indoors, release a large amount of heat into the facility, placing a heavy load on your building's HVAC system. Outdoor installation avoids this but exposes the unit to the elements.

Water-cooled systems export the heat outside via the cooling tower, having a minimal thermal impact on the facility. However, they require a constant water supply and chemical water treatment to prevent scale, corrosion, and biological growth.

Climate Considerations

The efficiency of an air-cooled chiller degrades as the ambient air temperature rises. In hot climates, it may struggle to provide sufficient cooling on the hottest days.

A water-cooled chiller's performance is much more stable and is largely independent of daily temperature swings, making it a more reliable choice in warmer regions.

Making the Right Choice for Your Application

Your decision should be guided by your specific operational priorities and constraints.

- If your primary focus is minimal initial investment and simple installation: An air-cooled chiller is often the most direct path, provided you can manage its exhausted heat and your climate is moderate.

- If your primary focus is long-term energy efficiency and stable performance: A water-cooled chiller is the superior technical choice, especially for larger furnaces or operations in warmer climates.

- If your facility has limited space or cannot tolerate a large internal heat load: A water-cooled system is more compact and effectively exports all process heat outside, making it the better fit.

By understanding these core differences, you can select a cooling strategy that ensures both the reliability of your vacuum furnace and the efficiency of your overall operation.

Summary Table:

| Chiller Type | Cooling Method | Key Advantages | Key Disadvantages |

|---|---|---|---|

| Air-Cooled | Uses ambient air and fans | Lower initial cost, simpler installation | Lower efficiency in hot climates, higher operating costs |

| Water-Cooled | Uses secondary water source and cooling tower | Higher efficiency, stable performance | Higher initial cost, requires water treatment |

Upgrade your laboratory's efficiency with KINTEK's advanced high-temperature furnace solutions!

Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable chiller systems tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements.

Don't let cooling challenges hold you back—contact us today to discuss how we can enhance your furnace performance and save on long-term costs!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- How do atmosphere furnaces contribute to ceramic manufacturing? Enhance Purity and Performance

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas