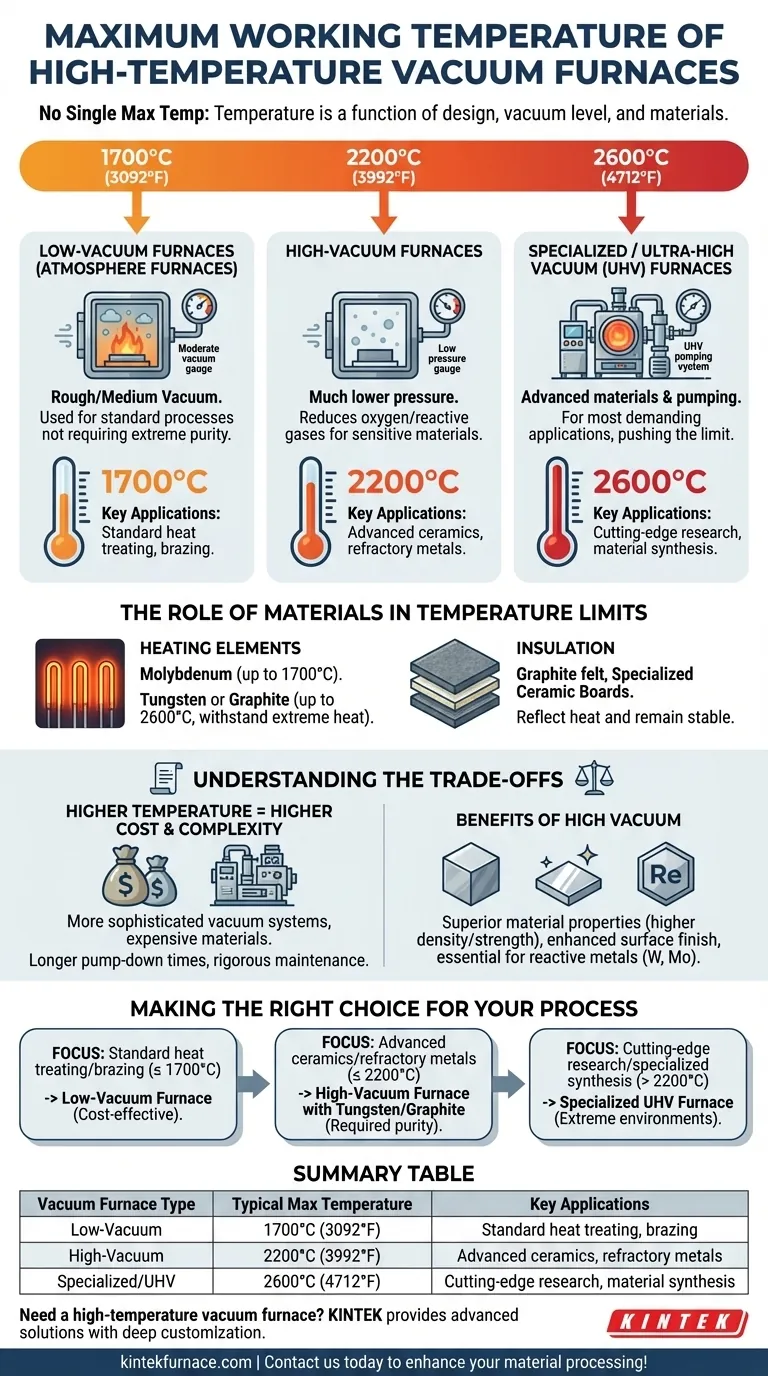

In practice, there is no single maximum temperature for all high-temperature vacuum furnaces. While many common high-vacuum models operate up to 2200°C (3992°F), the absolute maximum temperature can reach as high as 2600°C (4712°F) in highly specialized systems, with other designs limited to around 1700°C (3092°F).

The maximum temperature of a vacuum furnace is not a fixed value but a direct function of its design, determined primarily by the level of vacuum it can achieve and the materials used for its internal heating elements and insulation.

Why Temperature Varies: Vacuum Level is Key

The primary factor dictating a furnace's temperature ceiling is its ability to remove atmospheric gases. Different vacuum levels prevent heat loss and protect internal components, enabling higher temperatures.

Low-Vacuum Furnaces

These systems, sometimes called atmosphere furnaces, operate at rough or medium vacuum levels. They are typically used for processes that do not require an extremely pure environment.

Their maximum working temperature is generally limited to around 1700°C (3092°F).

High-Vacuum Furnaces

By achieving a much lower pressure, high-vacuum furnaces significantly reduce the presence of oxygen and other reactive gases. This protects sensitive materials and allows for much higher operational heat.

The typical maximum temperature for these furnaces rises to 2200°C (3992°F).

Specialized and Ultra-High Vacuum (UHV) Furnaces

For the most demanding applications, such as sintering refractory metals or growing specific types of crystals, specialized furnaces are required. These often feature advanced materials and UHV pumping systems.

These top-tier systems can push the operational limit to 2600°C (4712°F) or even slightly higher, representing the peak of current commercial technology.

The Role of Materials in Temperature Limits

Beyond the vacuum pump system, the physical materials used to construct the furnace's "hot zone" create a hard limit on its maximum temperature.

Heating Elements

The material used for the heating elements is critical. Molybdenum elements are common but are typically limited to around 1700°C. To achieve higher temperatures, furnaces must use elements made from tungsten or graphite, which can withstand extreme heat without degrading.

Insulation

The furnace chamber must be lined with insulation that can reflect heat and remain stable. Common choices include layers of graphite felt or specialized ceramic boards, which are selected based on the furnace's target temperature range.

Understanding the Trade-offs

Achieving higher temperatures in a vacuum environment is not without its challenges and costs. It's crucial to weigh the benefits against the practical limitations.

Higher Temperature = Higher Cost

There is a direct correlation between maximum temperature and price. Furnaces capable of reaching 2200°C or more require more sophisticated vacuum systems and are built with more expensive materials, leading to significantly higher equipment costs.

Performance vs. Practicality

High and ultra-high vacuum systems require longer pump-down times to reach their target pressure. They are also more complex systems that demand more rigorous and specialized maintenance to ensure leak-free performance.

The Benefits of High Vacuum

Despite the costs, the advantages are significant. A high-vacuum environment produces parts with superior material properties, such as higher density and strength. It also delivers an enhanced surface finish and is essential for processing reactive metals like tungsten and molybdenum that would be destroyed by oxygen at high temperatures.

Making the Right Choice for Your Process

Selecting the correct furnace requires matching its capabilities to your specific application and material requirements.

- If your primary focus is standard heat treating or brazing (up to 1700°C): A low-vacuum or atmosphere furnace is often the most cost-effective and practical solution.

- If your primary focus is processing advanced ceramics or refractory metals (up to 2200°C): A true high-vacuum furnace with tungsten or graphite elements is necessary to achieve the required purity and temperature.

- If your primary focus is cutting-edge research or specialized material synthesis (above 2200°C): You will need a specialized, often custom-built, ultra-high vacuum furnace designed for extreme environments.

Ultimately, the right choice depends on a clear understanding of the temperatures and atmospheric purity your material demands.

Summary Table:

| Vacuum Furnace Type | Typical Max Temperature | Key Applications |

|---|---|---|

| Low-Vacuum | 1700°C (3092°F) | Standard heat treating, brazing |

| High-Vacuum | 2200°C (3992°F) | Advanced ceramics, refractory metals |

| Specialized/UHV | 2600°C (4712°F) | Cutting-edge research, material synthesis |

Need a high-temperature vacuum furnace tailored to your lab's unique requirements? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we ensure precise performance for your experiments. Contact us today to enhance your material processing with reliable, high-performance equipment!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today