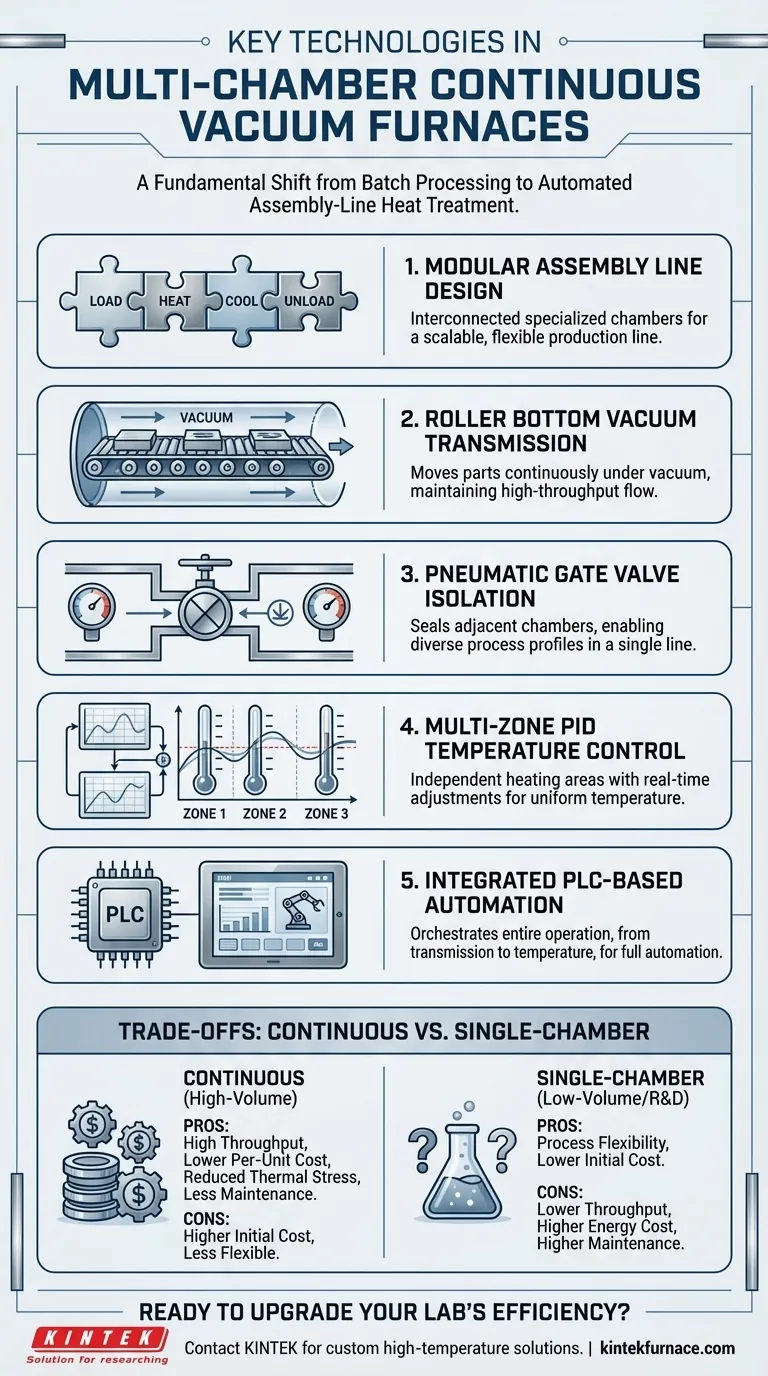

At their core, multi-chamber continuous vacuum furnaces are built upon five key technological pillars. These are a modular assembly line design, a roller bottom system for continuous transmission under vacuum, pneumatic gate valves for chamber isolation, multi-zone PID for precise temperature control, and an integrated PLC-based system for full automation.

A multi-chamber continuous vacuum furnace is not just a better furnace; it is a fundamental shift from batch processing to a fully automated, assembly-line approach for heat treatment under vacuum. The integration of its core technologies is what enables significant gains in throughput, energy efficiency, and operational reliability.

The Foundation: A Modular Assembly Line Design

What "Modular" Means

A continuous vacuum furnace is constructed as a series of interconnected, specialized chambers or modules. Each module is designed to perform a specific step in the process, such as loading, pre-heating, high-temperature treatment, cooling, and unloading.

The Strategic Advantage

This modular design allows for a flexible and scalable production line. You can configure the furnace to match the exact steps of your process, such as vacuum brazing, sintering, or metal heat treatment, by arranging the modules in the required sequence.

Enabling Continuous Flow: Transmission and Isolation

Roller Bottom Vacuum Continuous Transmission

To move parts from one chamber to the next without breaking the vacuum, these furnaces use a roller bottom transmission system. This is essentially a robust conveyor belt made of specialized rollers designed to operate reliably within the high-temperature, low-pressure vacuum environment.

This system is the mechanical backbone of the "continuous" process, physically transporting workloads through the entire heating and cooling cycle automatically.

Pneumatic Gate Valve Isolation

Between each chamber, pneumatic gate valves act as high-integrity doors. These valves slide open to allow parts to pass through and then seal shut to isolate each chamber from its neighbors.

This isolation is critical. It allows the furnace to maintain different temperatures, vacuum levels, or gas atmospheres in adjacent chambers simultaneously, enabling a complex process profile along a single line. The use of composite materials ensures they can withstand extreme temperature differentials.

Achieving Process Precision: Temperature Control

Multi-Zone PID Closed-Loop Control

To achieve uniform and precise temperatures, these furnaces employ multi-zone PID closed-loop program control. PID (Proportional-Integral-Derivative) is a sophisticated control algorithm that continuously adjusts heating power to maintain a set temperature with extreme accuracy.

The "multi-zone" aspect means the furnace is divided into several independent heating areas. Each zone has its own sensor and controller, allowing for the creation of complex temperature profiles required for advanced materials processing.

Automating the Entire Process: The Control System

Integrated PLC and HMI Control

The entire furnace operates automatically under the command of a Programmable Logic Controller (PLC). The PLC is a rugged industrial computer that orchestrates every action, from roller movement and valve operation to temperature regulation.

Operators interact with the system through a Human-Machine Interface (HMI), typically a touch screen. This interface provides real-time visualization of the process, allows for program selection, and logs all critical operational data for quality control and analysis.

Understanding the Trade-offs: Continuous vs. Single-Chamber

The Throughput and Efficiency Advantage

The primary benefit of a multi-chamber continuous furnace is a massive increase in process throughput. By eliminating the need to heat up and cool down a single chamber for every batch, it dramatically reduces cycle time and lowers energy costs per part.

The Maintenance and Reliability Advantage

Single-chamber furnaces experience significant stress from constant thermal cycling (heating and cooling). Continuous furnaces keep hot zones consistently hot and cool zones cool, which significantly reduces thermal stress on components like heating elements and insulation, leading to lower maintenance costs and longer equipment life.

The Initial Investment and Flexibility Consideration

The main trade-off is higher initial capital cost and complexity. These systems are optimized for high-volume, standardized production. They are less suitable for low-volume R&D or job shops that require frequent changes between vastly different processes and part sizes.

Making the Right Choice for Your Goal

A multi-chamber furnace represents a strategic investment in a specific production philosophy. Use these points to guide your decision.

- If your primary focus is maximizing throughput and lowering per-unit cost: The continuous furnace is the definitive choice for high-volume, repeatable production of parts like electronic devices or sintered components.

- If your primary focus is process flexibility for diverse, low-volume jobs: A traditional single-chamber batch furnace remains a more practical and cost-effective solution.

- If your primary focus is reducing long-term operational and maintenance costs: The energy savings and reduced thermal cycling of a continuous furnace provide a compelling long-term financial advantage in a high-volume setting.

Ultimately, choosing this technology is about committing to an automated, assembly-line model for your vacuum processing needs.

Summary Table:

| Technology | Key Function | Benefit |

|---|---|---|

| Modular Assembly Line Design | Interconnects specialized chambers for specific process steps | Enables flexible, scalable production lines |

| Roller Bottom Vacuum Transmission | Moves parts continuously under vacuum | Supports automated, high-throughput processing |

| Pneumatic Gate Valve Isolation | Seals chambers to maintain different conditions | Allows complex process profiles and chamber isolation |

| Multi-Zone PID Control | Provides precise, independent temperature regulation | Ensures uniform heating and accurate temperature profiles |

| Integrated PLC-Based System | Automates all furnace operations | Enhances reliability, data logging, and ease of use |

Ready to upgrade your lab's efficiency with custom high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnace technologies tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Contact us today to discuss how our multi-chamber continuous vacuum furnaces can boost your throughput and reduce costs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion