Yes, brazing in a vacuum is not only possible but is a highly effective and precise industrial process. Known as vacuum brazing, this method involves heating parts assembled with a filler metal inside a vacuum furnace. The absence of atmosphere prevents oxidation, eliminates the need for chemical flux, and produces exceptionally clean, strong, and reliable joints.

Vacuum brazing trades the simplicity of traditional methods for unparalleled cleanliness and control. It is a strategic choice for high-value applications where joint integrity and material purity are non-negotiable.

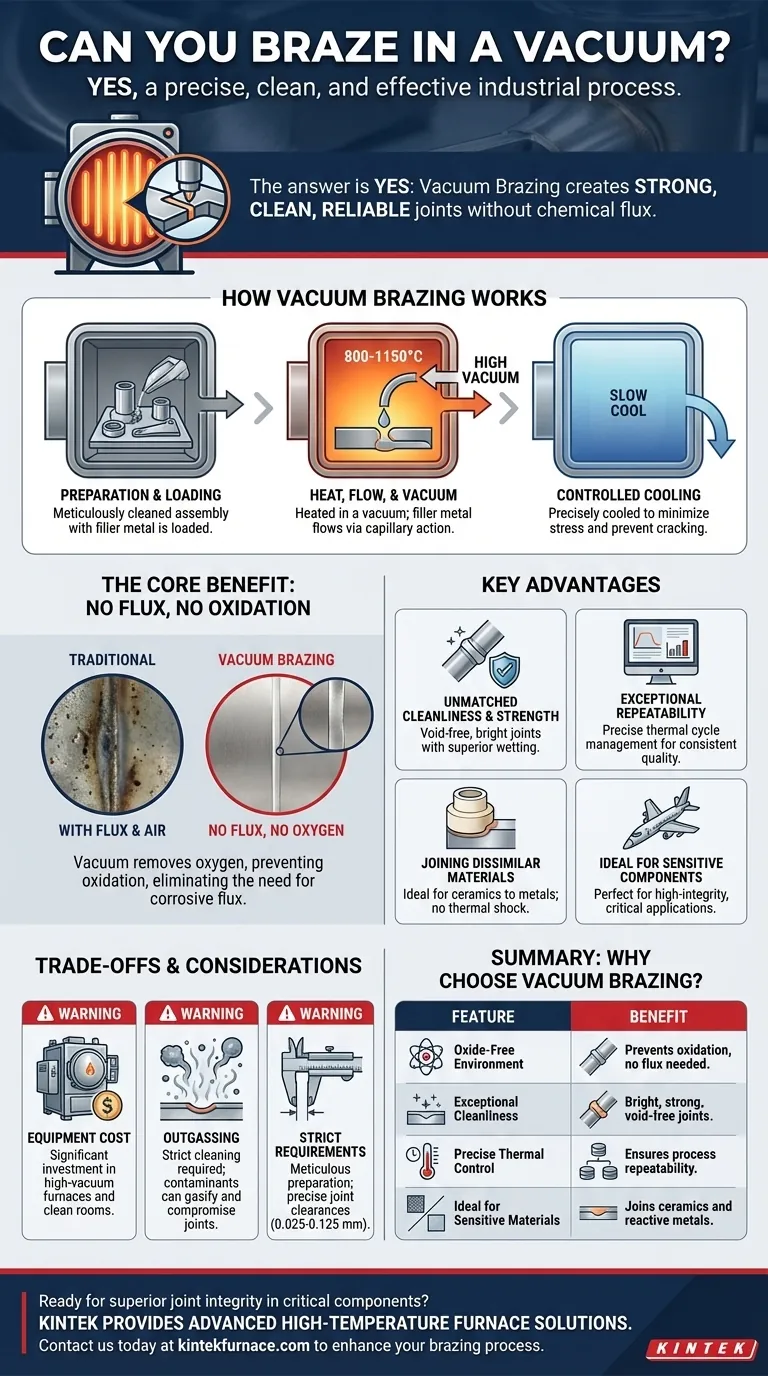

How Vacuum Brazing Works

Vacuum brazing is a furnace-based process that relies on a controlled environment rather than a direct flame. This fundamental difference is the source of its unique advantages and requirements.

The Core Process: Heat, Flow, and Cool

First, the components are meticulously cleaned and assembled, with the brazing filler metal placed at the joints. The entire assembly is then loaded into a vacuum furnace.

The furnace chamber is pumped down to a high vacuum, removing air and other atmospheric gases. The assembly is then heated to a specific temperature, typically between 800°C and 1150°C, which is above the filler metal's melting point (its liquidus temperature).

After a short hold at this temperature to allow the filler metal to flow into the joints via capillary action, the assembly is slowly and precisely cooled. This controlled cooling minimizes internal stresses and prevents cracking.

The Role of the Vacuum

The vacuum environment is the key to the process. By removing oxygen, it prevents the formation of oxides on the metal surfaces as they are heated.

Because no oxides form, there is no need for flux—the corrosive chemical paste used in other brazing methods to clean the metal. This results in a cleaner final product without any entrapped flux residue that could cause corrosion later.

Protective Atmospheres

In some cases, the process is run in a partial vacuum backfilled with a pure, inert gas like argon. This can help control the vaporization of certain elements from the base metals or filler alloy at high temperatures and low pressures.

Key Advantages of Vacuum Brazing

Choosing vacuum brazing is a deliberate decision to prioritize quality and repeatability over speed and portability.

Unmatched Joint Cleanliness and Strength

The resulting joints are free of flux and oxides, making them exceptionally clean and bright. This pristine environment allows for superior wetting by the filler metal, leading to void-free joints with maximum strength.

Exceptional Process Repeatability

Vacuum furnaces are computer-controlled, allowing for precise management of the entire thermal cycle—heating rates, hold times, and cooling rates. This ensures that every part is processed identically, which is critical for series production and quality assurance.

Joining Dissimilar and Sensitive Materials

The slow, uniform heating and cooling of a furnace environment is far less aggressive than a direct flame. This makes it ideal for joining delicate or dissimilar materials, such as ceramics to metals, without causing thermal shock or distortion.

Understanding the Trade-offs and Challenges

The precision of vacuum brazing comes with a set of demanding requirements and potential difficulties.

Significant Equipment and Infrastructure

Vacuum brazing requires a significant investment in equipment. High-vacuum furnaces, clean assembly rooms, and sophisticated process control systems are expensive and require specialized maintenance.

The Problem of Outgassing

Any contaminants on the parts—such as residual cleaning fluids, oils, or even water vapor—will turn into a gas (outgas) in the vacuum. This can contaminate the environment and compromise the joint. Binders used in brazing pastes must also be carefully managed to ensure they burn off cleanly without leaving residue.

Strict Process Requirements

Success depends on meticulous preparation. Joint clearances must be precisely controlled, typically between 0.025 mm and 0.125 mm, to facilitate proper capillary action. Parts must be scrupulously cleaned, as the vacuum will not remove existing dirt or thick oxide layers.

When to Choose Vacuum Brazing

The decision to use vacuum brazing should be based on the specific goals of your project.

- If your primary focus is high-integrity, critical components: Vacuum brazing provides the strength, purity, and repeatability required for aerospace, medical, and advanced industrial applications.

- If your primary focus is joining sensitive or dissimilar materials: The precise thermal control of a vacuum furnace is ideal for joining complex assemblies, especially those involving ceramics or reactive metals.

- If your primary focus is speed, portability, or low-cost repairs: A simpler method like torch or induction brazing is a more practical and accessible choice.

By understanding its demanding requirements, you can leverage vacuum brazing to achieve a level of joint quality that other methods simply cannot match.

Summary Table:

| Feature | Benefit |

|---|---|

| Oxide-Free Environment | Prevents oxidation, eliminating the need for chemical flux. |

| Exceptional Joint Cleanliness | Produces bright, strong, void-free joints without entrapped flux residue. |

| Precise Thermal Control | Ensures process repeatability and is ideal for delicate or dissimilar materials. |

| Ideal for Sensitive Materials | Suitable for joining ceramics to metals and reactive metals without thermal shock. |

Ready to achieve superior joint integrity for your critical components?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique vacuum brazing requirements.

Contact us today to discuss how our vacuum furnaces can enhance your brazing process and deliver unmatched quality.

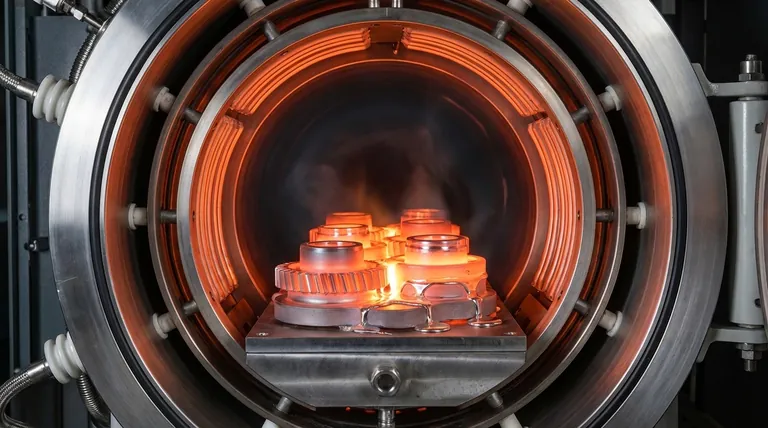

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering