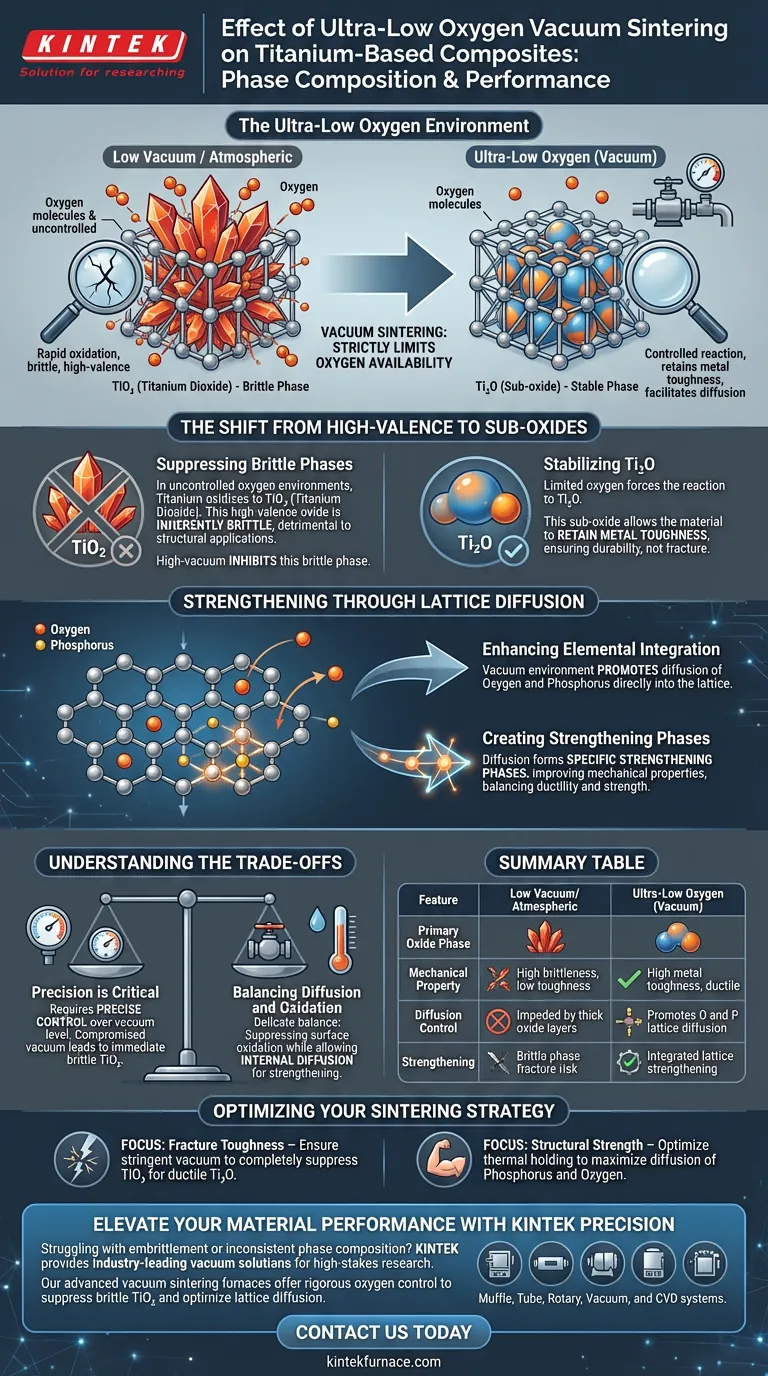

The ultra-low oxygen environment in a vacuum sintering furnace fundamentally alters the phase composition of titanium-based composites by strictly limiting the availability of oxygen. Instead of forming brittle, high-valence oxides like titanium dioxide (TiO2), the controlled vacuum forces the formation of stable sub-oxides, specifically Ti2O.

By regulating oxygen partial pressure, vacuum sintering prevents the embrittlement typical of standard oxidation. It preserves the metal’s intrinsic toughness while simultaneously facilitating the diffusion of strengthening elements into the titanium lattice.

The Shift from High-Valence to Sub-Oxides

Suppressing Brittle Phases

In environments with uncontrolled oxygen, titanium rapidly oxidizes to form TiO2 (titanium dioxide).

This high-valence oxide phase is detrimental to structural applications because it is inherently brittle.

The high-vacuum environment lowers the oxygen partial pressure enough to effectively inhibit the formation of this brittle phase.

Stabilizing Ti2O

With oxygen availability strictly limited, the chemical reaction is forced into a different pathway.

The titanium reacts to form Ti2O, a sub-oxide phase.

Unlike TiO2, Ti2O allows the material to retain its metal toughness, ensuring the composite remains durable rather than prone to fracture.

Strengthening Through Lattice Diffusion

Enhancing Elemental Integration

Beyond preventing bad oxides, the vacuum environment actively promotes beneficial internal changes.

It facilitates the diffusion of oxygen and phosphorus atoms directly into the titanium lattice.

Creating Strengthening Phases

This diffusion process is not merely a side effect; it is a strengthening mechanism.

As oxygen and phosphorus integrate into the lattice, they form specific strengthening phases within the material.

This results in a scaffold with improved overall mechanical properties, balancing ductility with increased strength.

Understanding the Trade-offs

Precision is Critical

While the formation of Ti2O is desirable, it requires precise control over the vacuum level.

If the vacuum is compromised or insufficient, the oxygen partial pressure will rise, leading to the immediate formation of brittle TiO2.

Balancing Diffusion and Oxidation

There is a delicate balance between removing oxygen to prevent TiO2 and allowing enough mobility for diffusion.

Process parameters must be tuned to ensure that while surface oxidation is suppressed, the internal diffusion of phosphorus and oxygen still occurs to provide the necessary strengthening.

Optimizing Your Sintering Strategy

To leverage these phase transformations effectively, you must align your furnace parameters with your specific mechanical goals.

- If your primary focus is Fracture Toughness: Ensure your vacuum levels are stringent enough to completely suppress TiO2 formation in favor of the ductile Ti2O phase.

- If your primary focus is Structural Strength: Optimize thermal holding times to maximize the diffusion of phosphorus and oxygen into the lattice for hardening.

Success relies on maintaining a vacuum environment that is rigorous enough to protect the metal, yet conducive to the internal chemistry that builds strength.

Summary Table:

| Feature | Low Vacuum/Atmospheric | Ultra-Low Oxygen (Vacuum) |

|---|---|---|

| Primary Oxide Phase | TiO2 (Titanium Dioxide) | Ti2O (Sub-oxide) |

| Mechanical Property | High brittleness, low toughness | High metal toughness, ductile |

| Diffusion Control | Impeded by thick oxide layers | Promotes O and P lattice diffusion |

| Strengthening | Brittle phase fracture risk | Integrated lattice strengthening |

Elevate Your Material Performance with KINTEK Precision

Are you struggling with material embrittlement or inconsistent phase composition in your titanium alloys? KINTEK provides industry-leading vacuum solutions tailored for high-stakes aerospace, medical, and industrial research. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique high-temperature processing needs.

Our advanced vacuum sintering furnaces provide the rigorous oxygen partial pressure control required to suppress brittle TiO2 and optimize lattice diffusion. Contact us today to consult with our technical specialists and discover how our high-performance lab equipment can transform your composite manufacturing.

Visual Guide

References

- Xingping Fan, Hao Zhang. Fabrication and Characterization of LaF3-Reinforced Porous HA/Ti Scaffolds. DOI: 10.3390/coatings14010111

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What is the operating mechanism of a catalytic degreasing furnace? Master 17-4 PH Stainless Steel Debinding

- How does a vacuum heating furnace contribute to the pre-treatment of samples before thin-film deposition? Ensure Adhesion

- How do the radiant heating and controlled cooling functions of a vacuum brazing furnace benefit Kovar-to-SS joints?

- What is the function of computer-controlled systems in modern vacuum furnaces? Achieve Unwavering Precision & Repeatability

- How does vacuum carburizing improve operational efficiency? Boost Speed, Quality, and Cost Savings

- Why is it necessary to evacuate a furnace to 10⁻³ Pa before melting AM60 magnesium alloy? Prevent Oxidation & Ensure Quality

- What is the function of a vacuum system in the vacuum distillation recovery process for magnesium alloys?

- How does a vacuum pump contribute to the formation of MoS2 dot structures? Master Precision Nanoscale Growth Control