In modern vacuum furnaces, the primary function of computer-controlled systems is to automate and precisely manage every stage of the heat treatment cycle. These systems execute pre-programmed recipes to control variables like temperature, vacuum levels, and gas flow, ensuring that each metallurgical process is performed with exceptional precision and consistency, cycle after cycle.

The core purpose of computer control is to elevate heat treatment from a variable craft into a predictable, data-driven manufacturing process. It's not just about automation; it's about guaranteeing unwavering quality, minimizing costly errors, and optimizing operational efficiency.

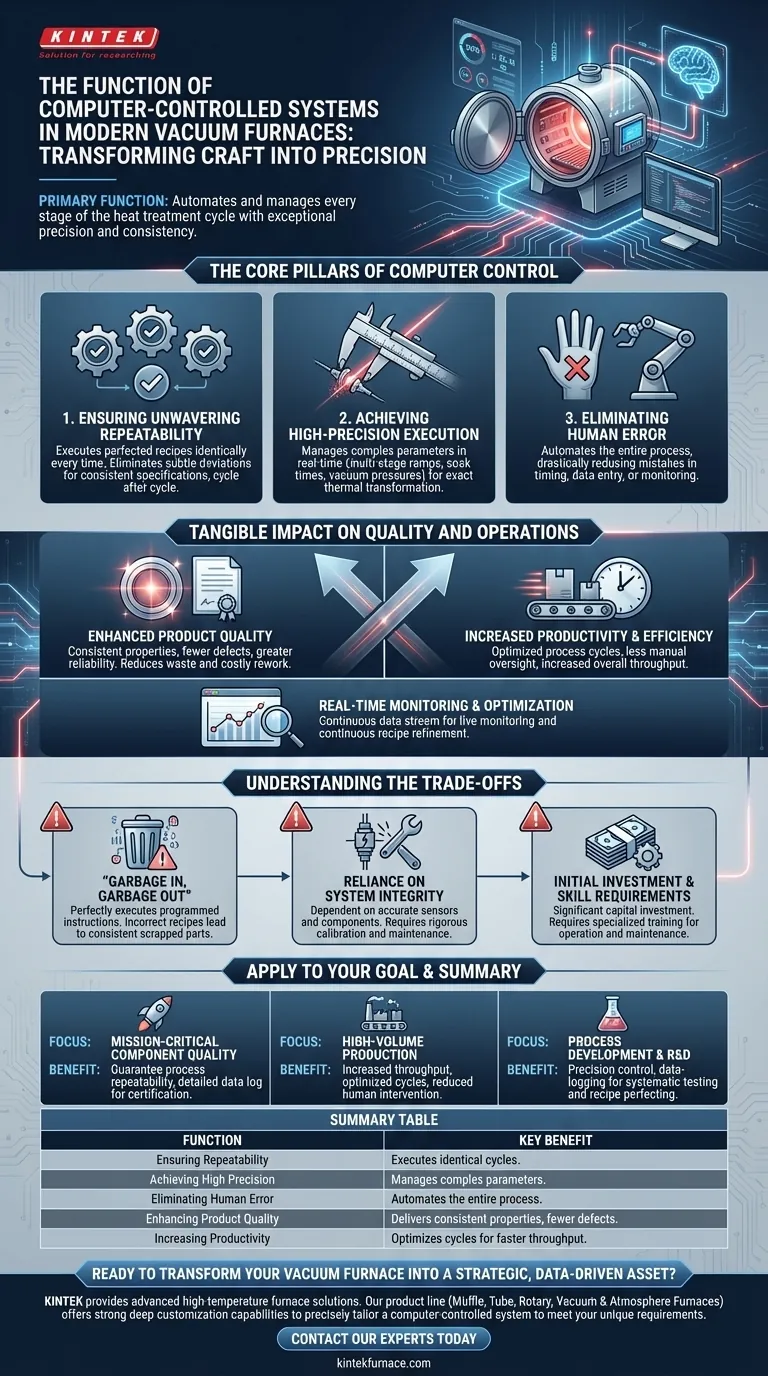

The Core Pillars of Computer Control

Modern manufacturing, especially in high-stakes industries like aerospace and medical, cannot tolerate variability. Computer-controlled systems provide the foundation for reliability by focusing on three critical functions.

Ensuring Unwavering Repeatability

The most crucial function of a computer control system is to ensure metallurgical repeatability.

Once a heat treatment recipe is perfected and programmed, the system executes it identically every single time. This eliminates the subtle deviations that can occur with manual operation, guaranteeing that every batch of parts meets the exact same specifications.

Achieving High-Precision Execution

These systems offer a level of precision that is impossible to achieve manually.

They manage complex parameters in real-time, such as multi-stage temperature ramp rates, precise soak times, and specific vacuum pressures. This ensures the material undergoes the exact intended thermal transformation.

Eliminating Human Error

A significant advantage of this technology is the drastic reduction of human error.

Manual furnace operation is susceptible to mistakes in timing, data entry, or process monitoring. By automating the entire cycle, the computer system removes this significant variable, leading to a far more reliable and stable production environment.

The Tangible Impact on Quality and Operations

Implementing computer control is not just a technical upgrade; it delivers measurable improvements to both the final product and the efficiency of the entire operation.

Enhanced Product Quality

The direct result of precision and repeatability is a higher-quality end product.

Parts treated in a computer-controlled furnace exhibit more consistent metallurgical properties, fewer defects, and greater reliability. This leads to a reduction in waste and costly rework.

Increased Productivity and Efficiency

Automation allows for optimized process cycles.

Systems can be programmed for rapid heating and cooling where appropriate, and workpiece movement can be pre-set. This, combined with less need for constant manual oversight, increases the overall throughput of the furnace.

Real-Time Monitoring and Optimization

These systems provide a continuous stream of data on every furnace cycle.

Operators can monitor the process in real-time to ensure everything is running to specification. Furthermore, this data can be logged and analyzed to continuously refine and optimize heat treatment recipes for better results and efficiency.

Understanding the Trade-offs

While the benefits are substantial, it's important to approach this technology with a clear understanding of its requirements and potential pitfalls.

The "Garbage In, Garbage Out" Principle

A computer control system will execute its programmed instructions with perfect precision.

This means that an incorrect or poorly designed heat treatment recipe will be repeated perfectly, leading to consistently scrapped parts. The expertise lies in developing the correct process parameters.

Reliance on System Integrity

The system's performance is entirely dependent on the accuracy of its sensors and electromechanical components.

A faulty thermocouple or a malfunctioning valve can compromise an entire batch. Therefore, a rigorous calibration and preventive maintenance schedule is critical to realizing the benefits of automation.

Initial Investment and Skill Requirements

Advanced computer-controlled furnaces represent a significant capital investment compared to simpler manual models.

Furthermore, they require personnel with the technical skills to program, operate, and maintain the systems effectively. This may necessitate specialized training for your team.

How to Apply This to Your Goal

The value of a computer-controlled system is best understood through the lens of your specific operational objective.

- If your primary focus is mission-critical component quality: The system's ability to guarantee process repeatability and provide a detailed data log for certification is its most indispensable feature.

- If your primary focus is high-volume production: The key benefit is increased throughput and efficiency, achieved through optimized, automated cycles that reduce human intervention and minimize waste.

- If your primary focus is process development and R&D: The system's precision control and data-logging capabilities are essential for systematically testing variables and perfecting new heat treatment recipes.

Ultimately, computer-controlled systems transform a vacuum furnace from a simple piece of equipment into a strategic, data-driven manufacturing asset.

Summary Table:

| Function | Key Benefit |

|---|---|

| Ensuring Repeatability | Executes identical cycles for consistent metallurgical results. |

| Achieving High Precision | Manages complex parameters like temperature ramp rates and vacuum levels. |

| Eliminating Human Error | Automates the entire process to remove manual operation risks. |

| Enhancing Product Quality | Delivers consistent properties, fewer defects, and less waste. |

| Increasing Productivity | Optimizes cycles for faster throughput and reduced oversight. |

Ready to transform your vacuum furnace into a strategic, data-driven asset?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, and Vacuum & Atmosphere Furnaces, is complemented by strong deep customization capabilities. We can precisely tailor a computer-controlled system to meet your unique requirements for mission-critical quality, high-volume production, or advanced R&D.

Contact our experts today to discuss how our solutions can guarantee unwavering quality and optimize your heat treatment operations.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties