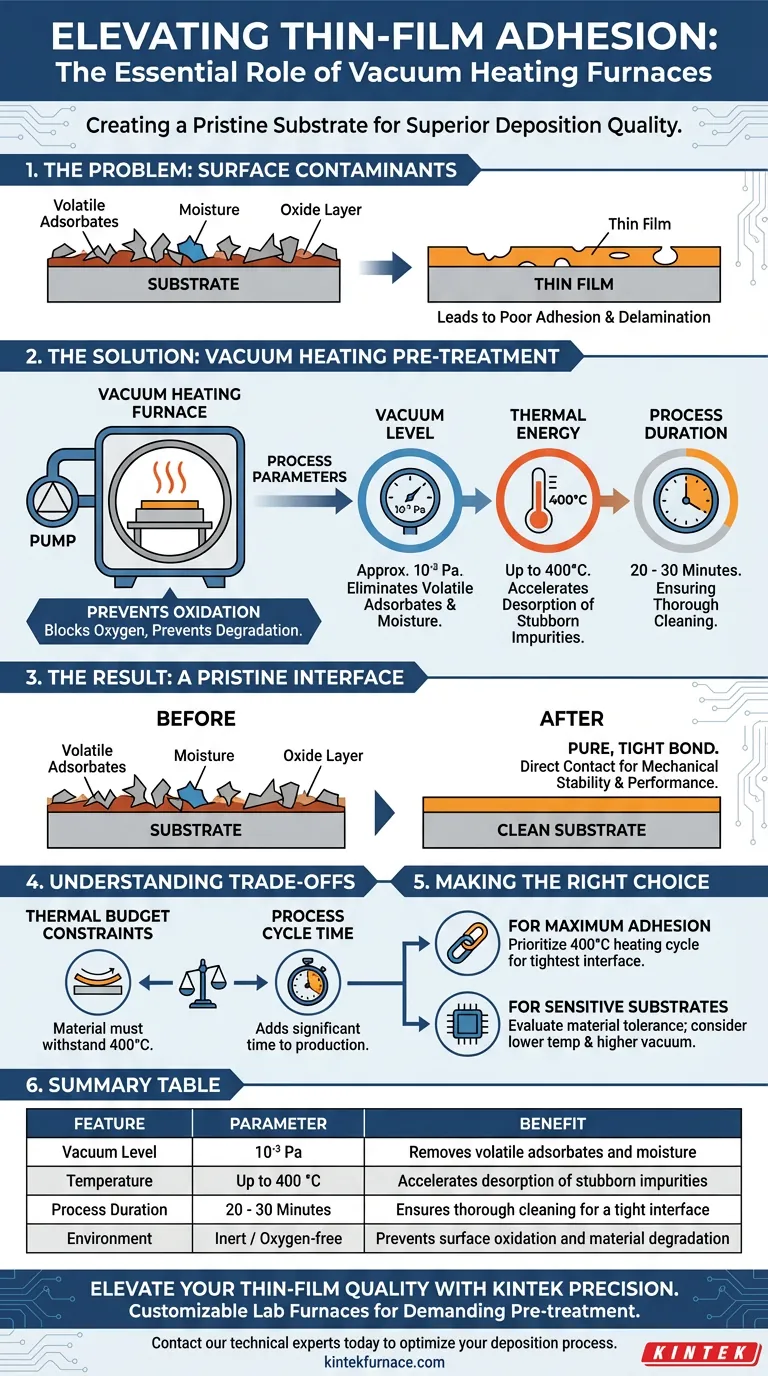

A vacuum heating furnace is essential for ensuring thin-film adhesion by creating a pristine substrate surface prior to deposition. By maintaining a high-vacuum environment of approximately 10⁻³ Pa and heating samples to 400 °C for 20 to 30 minutes, the furnace utilizes vacuum degassing to strip away volatile adsorbates that would otherwise compromise the film's quality.

Core Takeaway: The success of thin-film deposition relies heavily on the quality of the substrate interface. Vacuum heating serves as a critical purification step, eliminating microscopic contaminants and surface oxidation to ensure a pure, tight bond between the film and the substrate.

The Mechanism of Purification

Vacuum Degassing

The primary function of the furnace is vacuum degassing. By lowering the pressure to 10⁻³ Pa, the system lowers the vapor pressure required for contaminants to evaporate. This forces volatile adsorbates—gases or moisture stuck to the surface—to release from the sample.

The Role of Thermal Energy

Heat is the catalyst that accelerates this cleaning process. Maintaining the sample at 400 °C provides the kinetic energy necessary to detach stubborn impurities from the single-crystal substrate. A duration of 20 to 30 minutes ensures that this desorption is thorough and complete.

Preventing Oxidation

Beyond cleaning, the vacuum environment plays a defensive role. By effectively blocking oxygen, the furnace creates a barrier against rapid oxidation. This allows the metal or substrate to reach high temperatures without forming an oxide layer that would degrade the electrical or structural properties of the subsequent film.

Why Interface Integrity Matters

Eliminating Weak Links

If volatile adsorbates remain on the surface, they act as a barrier between the substrate and the deposited film. This leads to poor adhesion, delamination, or voids in the film structure.

Ensuring a "Tight" Interface

The vacuum heating process guarantees a "pure and tight" interface. This direct contact between the clean single-crystal substrate and the thin film is vital for the mechanical stability and performance consistency of the final product.

Understanding the Trade-offs

Thermal Budget Constraints

While 400 °C is effective for cleaning, it introduces a thermal constraint. You must verify that your specific substrate material can withstand this temperature without degrading or warping before the deposition even begins.

Process Cycle Time

Implementing this pre-treatment adds a significant time cost to the production cycle. The 20 to 30-minute hold time, combined with the time required to pump down to 10⁻³ Pa and ramp up the temperature, reduces overall manufacturing throughput.

Making the Right Choice for Your Goal

To maximize the effectiveness of your thin-film deposition, align your pre-treatment parameters with your specific requirements.

- If your primary focus is maximum adhesion: Prioritize the full 400 °C heating cycle to ensure the complete removal of all volatile adsorbates for the tightest possible interface.

- If your primary focus is sensitive substrates: Evaluate if the material can tolerate the standard 400 °C protocol, or if a lower temperature with a higher vacuum level is necessary to prevent damage.

A clean interface is not merely a preparation step; it is the foundation of a durable and high-performance thin film.

Summary Table:

| Feature | Parameter | Benefit |

|---|---|---|

| Vacuum Level | 10⁻³ Pa | Removes volatile adsorbates and moisture |

| Temperature | Up to 400 °C | Accelerates desorption of stubborn impurities |

| Process Duration | 20 - 30 Minutes | Ensures thorough cleaning for a tight interface |

| Environment | Inert / Oxygen-free | Prevents surface oxidation and material degradation |

Elevate Your Thin-Film Quality with KINTEK Precision

Don't let surface contaminants compromise your material performance. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Muffle, Tube, Rotary, and Vacuum CVD systems tailored for your most demanding pre-treatment needs. Our customizable lab high-temperature furnaces are designed to deliver the precise vacuum levels and thermal stability required for superior substrate-film adhesion.

Ready to optimize your deposition process? Contact our technical experts today to discover how KINTEK’s advanced heating solutions can bring consistency and durability to your research and production.

Visual Guide

References

- Maria A. Dias, Ralf Dohmen. Experimental determination of Fe–Mg interdiffusion in orthopyroxene as a function of Fe content. DOI: 10.1007/s00410-024-02110-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What temperature range can vacuum furnaces achieve? Unlock High-Temp Precision for Your Lab

- Why are vacuum melting furnaces particularly important for aerospace? Ensuring Material Purity for Extreme Reliability

- Why is it necessary to use a vacuum degassing station at 150 °C for sample treatment? Achieve Accurate CO2 Adsorption

- What are the main components of a vacuum furnace's internal structure? Optimize Your Heat Treatment Process

- How do thermal imagers and hybrid AI models facilitate leak detection? 92% Accuracy in Industrial Furnaces

- What is the primary application of vacuum heat treating furnaces in aerospace? Enhance Component Performance with Precision

- How do customized vacuum furnaces improve product quality? Achieve Superior Heat Treatment for Your Materials

- What role does a high-temperature vacuum furnace play in sintering magnesium composites? Key Success Factors