At its core, a customized vacuum furnace improves product quality by creating an extremely pure, stable, and precisely controlled environment for heat treatment. This level of control eliminates atmospheric contamination and thermal inconsistencies, which are the primary sources of defects like oxidation, warping, and inconsistent mechanical properties in finished components.

The fundamental advantage of a customized vacuum furnace is its ability to tailor the heating, cooling, and vacuum parameters to the unique metallurgical requirements of a specific material. This transforms heat treatment from a generic, one-size-fits-all process into a scientifically optimized and repeatable manufacturing step.

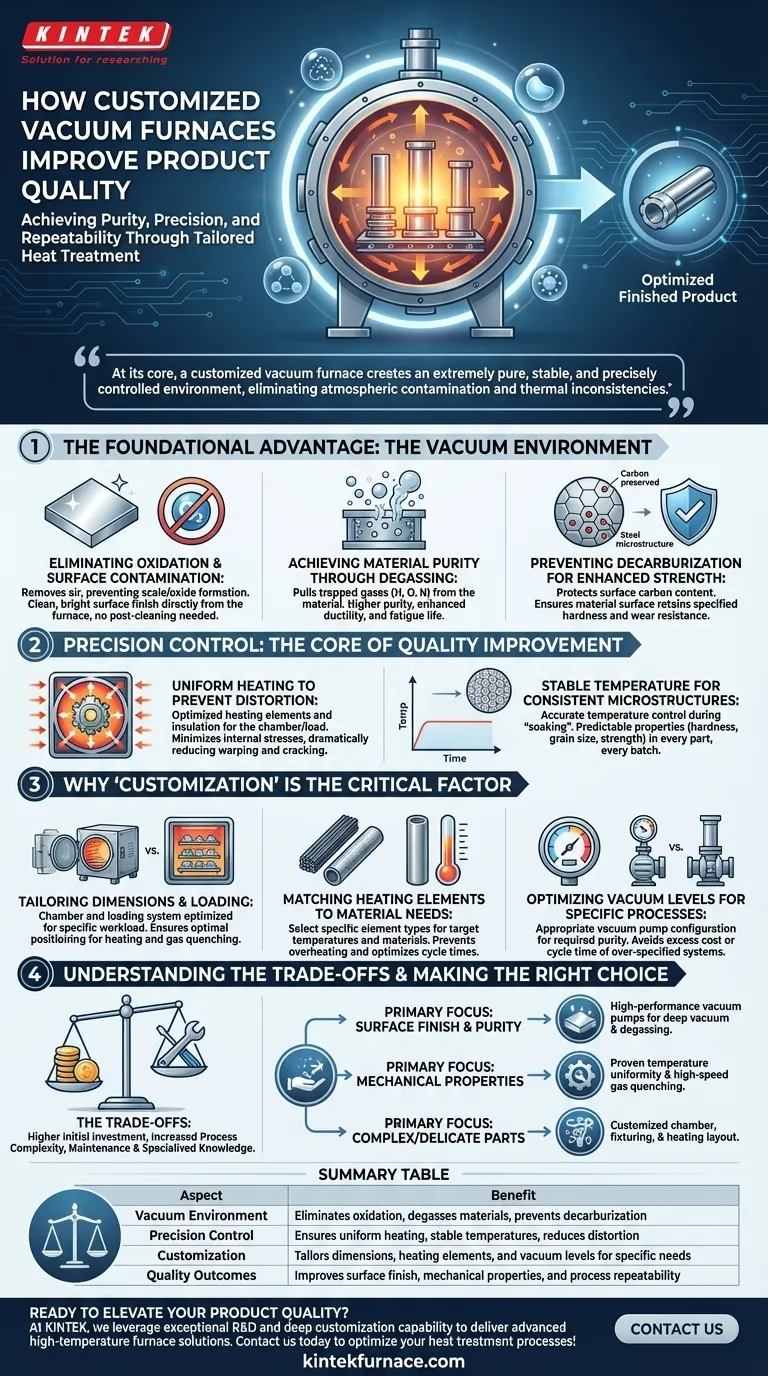

The Foundational Advantage: The Vacuum Environment

The primary function of a vacuum furnace is to remove the atmosphere—and all its contaminants—from the heating chamber. This has profound effects on the material being treated.

Eliminating Oxidation and Surface Contamination

By removing air, a vacuum furnace prevents oxygen from reacting with the hot metal surface. This completely eliminates the formation of scale or oxide layers.

The result is a clean, bright, and smooth surface finish straight out of the furnace, removing the need for post-process cleaning operations like sandblasting or acid pickling.

Achieving Material Purity Through Degassing

Many metals contain dissolved gases like hydrogen, oxygen, and nitrogen, which can compromise their structural integrity. The vacuum environment effectively pulls these trapped gases out of the material.

This degassing process results in a higher-purity metal with significantly improved mechanical properties, such as enhanced ductility and fatigue life.

Preventing Decarburization for Enhanced Strength

For many steel alloys, carbon content is critical to achieving desired hardness and strength. In a conventional furnace, the atmosphere can react with and deplete carbon from the steel's surface.

A vacuum furnace prevents this decarburization, ensuring the material's surface retains its specified hardness and wear resistance, which is vital for high-performance components.

Precision Control: The Core of Quality Improvement

Beyond just creating a vacuum, the ability to precisely manage the thermal cycle is what separates a high-quality process from an average one. Customization allows this control to be perfected.

Uniform Heating to Prevent Distortion

Customized furnaces are designed with heating elements and insulation optimized for a specific chamber size and load configuration. This ensures temperature uniformity across the entire part.

By heating every section of the component at the same rate, internal stresses are minimized, dramatically reducing the risk of warping, distortion, and cracking, especially in complex geometries.

Stable Temperature for Consistent Microstructures

Holding a stable and accurate temperature during the "soaking" phase is critical for achieving the desired metallurgical microstructure.

This process consistency ensures that every part in a batch, and every batch over time, has the same predictable properties like hardness, grain size, and strength.

Why "Customization" is the Critical Factor

While any vacuum furnace offers benefits, customization allows a facility to optimize the process for its specific parts and materials, unlocking the highest level of quality and efficiency.

Tailoring Dimensions and Loading

A standard furnace may be too large or small for your typical workload. A custom-designed furnace chamber and loading system ensures that parts are positioned optimally for uniform heating and gas quenching.

Matching Heating Elements to Material Needs

Different materials and processes demand different heating rates. Customization allows for the selection of specific heating element types (e.g., graphite, molybdenum) that are best suited for the target temperatures and materials, preventing overheating or slow cycle times.

Optimizing Vacuum Levels for Specific Processes

Not all processes require the deepest possible vacuum. Brazing, for example, has different requirements than annealing titanium. A customized system provides the appropriate vacuum pump configuration to achieve the necessary purity without the excess cost or cycle time of an over-specified system.

Understanding the Trade-offs

While highly effective, customized vacuum furnaces represent a significant technical and financial commitment. Objectivity requires acknowledging the associated challenges.

Higher Initial Investment

A furnace tailored to specific requirements will inherently have a higher upfront cost than a standard, off-the-shelf model. This investment must be justified by the expected improvements in product quality and yield.

Increased Process Complexity

Greater control means more variables to manage. Operating a customized furnace requires a deeper understanding of metallurgy and process control to dial in the optimal parameters for each job.

Maintenance and Specialized Knowledge

These are sophisticated pieces of equipment. Maintenance requires specialized knowledge of vacuum systems, controls, and high-temperature materials, which may necessitate additional training for staff.

Making the Right Choice for Your Goal

To determine if a customized vacuum furnace is the right solution, align its capabilities with your primary quality objectives.

- If your primary focus is surface finish and purity: Prioritize a design with high-performance vacuum pumps capable of deep vacuums and effective degassing.

- If your primary focus is mechanical properties (hardness/strength): Emphasize a design with proven temperature uniformity and a precisely controlled, high-speed gas quenching system.

- If your primary focus is processing complex or delicate parts: Focus on a customized chamber, fixturing, and heating element layout that minimizes thermal stress and distortion.

Ultimately, investing in a customized vacuum furnace is a commitment to moving beyond acceptable results and toward scientifically perfected, repeatable quality.

Summary Table:

| Aspect | Benefit |

|---|---|

| Vacuum Environment | Eliminates oxidation, degasses materials, prevents decarburization |

| Precision Control | Ensures uniform heating, stable temperatures, reduces distortion |

| Customization | Tailors dimensions, heating elements, and vacuum levels for specific needs |

| Quality Outcomes | Improves surface finish, mechanical properties, and process repeatability |

Ready to elevate your product quality with a customized vacuum furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering enhanced purity, precision, and performance. Contact us today to discuss how we can optimize your heat treatment processes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today