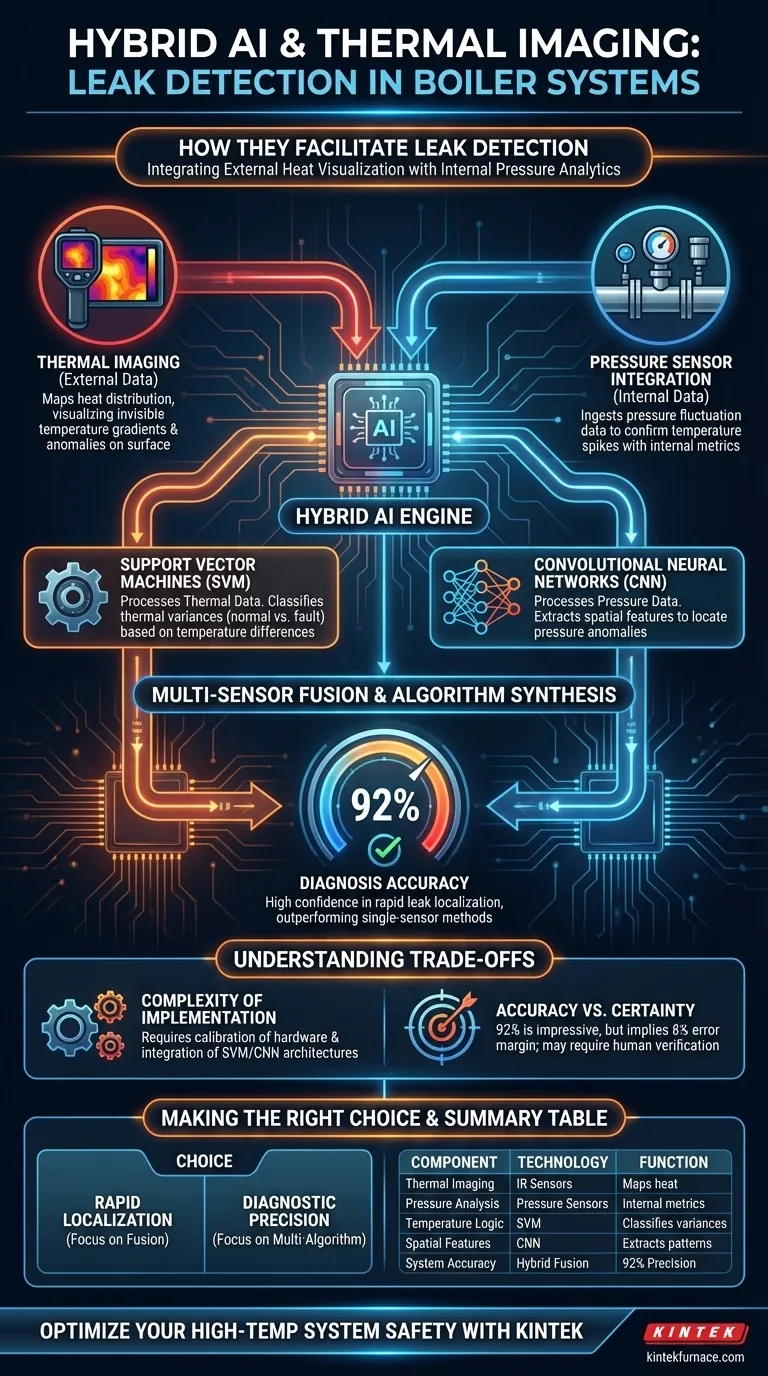

Thermal imagers and hybrid AI models facilitate leak detection by integrating external heat visualization with internal pressure analytics. This approach employs thermal cameras to map heat distribution across the system, while a specialized hybrid AI model interprets the data to classify faults. By fusing distinct algorithms—Support Vector Machines (SVM) and Convolutional Neural Networks (CNN)—the system provides a comprehensive diagnostic tool for high-temperature environments.

The core advantage of this approach is multi-sensor fusion: by combining temperature differences with pressure data, operators achieve a 92% diagnosis accuracy, enabling the rapid localization of leaks that single-sensor methods might miss.

The Architecture of Detection

To understand how this system works, you must look at how it captures physical data. The solution moves beyond simple visual inspection by correlating two distinct physical properties of the boiler system.

Thermal Imaging

The first line of defense is the thermal imager, which maps the heat distribution across the industrial boiler or furnace. This non-contact method visualizes temperature gradients that are invisible to the naked eye. It highlights anomalies in the surface temperature that often indicate the presence of an underlying leak.

Pressure Sensor Integration

While thermal images provide external data, the system also ingests data from pressure sensors. This internal metric adds a layer of depth to the diagnosis, confirming that temperature spikes correspond to actual pressure fluctuations within the system.

How the Hybrid AI Processes Data

The raw data from cameras and sensors is complex and difficult to interpret manually in real-time. A hybrid AI model solves this by dedicating specific algorithms to specific data types.

Support Vector Machines (SVM)

The system utilizes Support Vector Machines (SVM) to process the thermal data. Specifically, the SVM algorithm analyzes the temperature differences captured by the imagers. It classifies these thermal variances to determine if they fall within normal operating ranges or indicate a fault.

Convolutional Neural Networks (CNN)

Simultaneously, Convolutional Neural Networks (CNN) are applied to the pressure sensor data. The CNN is tasked with extracting spatial features from this pressure information. This allows the system to understand the "shape" and location of pressure anomalies within the boiler infrastructure.

The Power of Fusion

The final step is multi-sensor and multi-algorithm fusion. The system combines the temperature analysis from the SVM with the spatial feature analysis from the CNN. This synthesis results in a diagnosis accuracy of 92%, providing a high degree of confidence when identifying leaks.

Understanding the Trade-offs

While this hybrid approach offers high accuracy, it is essential to recognize the inherent limitations of reliance on probabilistic models.

Complexity of Implementation

This method is significantly more complex than standard monitoring. It requires the calibration of both thermal hardware and pressure sensors, as well as the integration of two distinct AI architectures (SVM and CNN).

Accuracy vs. Certainty

Although a 92% diagnosis accuracy is impressive for industrial standards, it implies an 8% margin of error. Operators must remain aware that while the system is highly reliable for rapid localization, it is not infallible and may still require human verification in ambiguous cases.

Making the Right Choice for Your Goal

When implementing leak detection systems in industrial boilers, align your technology choice with your operational priorities.

- If your primary focus is rapid fault localization: Rely on the hybrid model's ability to fuse data sources, which allows operators to locate leaks quickly in complex environments.

- If your primary focus is diagnostic precision: Prioritize the multi-algorithm approach, as the combination of SVM and CNN provides a 92% accuracy rate that outperforms single-sensor diagnostics.

By leveraging the synergy between thermal imaging and hybrid AI, you transform leak detection from a guessing game into a precise, data-driven science.

Summary Table:

| Component/Feature | Technology Used | Function in Leak Detection |

|---|---|---|

| Thermal Imaging | IR Sensors | Maps heat distribution and visualizes invisible anomalies |

| Pressure Analysis | Pressure Sensors | Provides internal metrics to confirm system fluctuations |

| Temperature Logic | SVM Algorithm | Classifies thermal variances to identify specific faults |

| Spatial Features | CNN Algorithm | Extracts and analyzes pressure patterns for localization |

| System Accuracy | Hybrid Fusion | Combines multi-sensor data for 92% diagnostic precision |

Optimize Your High-Temp System Safety

Don't let inefficient leak detection compromise your operations. KINTEK provides expert R&D and manufacturing for Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable for your unique industrial and laboratory needs.

Our advanced high-temperature furnaces are designed for precision and durability, ensuring you have the robust infrastructure needed to implement cutting-edge monitoring technologies.

Ready to upgrade your thermal processing equipment? Contact KINTEK today for a consultation and see how our customizable solutions can enhance your facility's efficiency and safety.

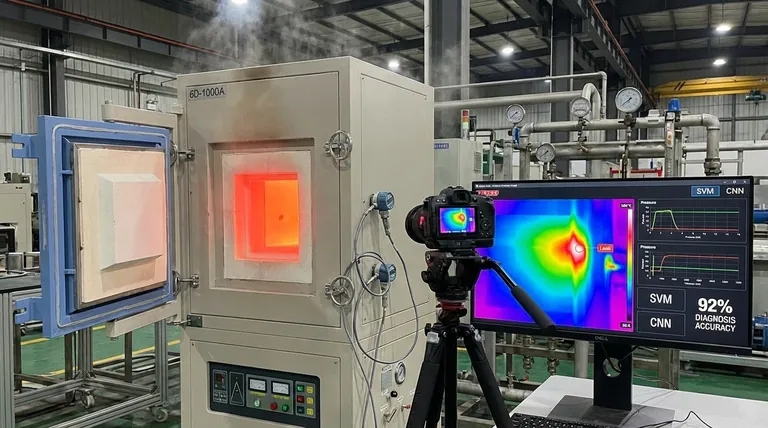

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the tool and die industry applications of furnace brazing? Boost Performance and Cut Costs

- Why is repeated flipping and remelting necessary in vacuum arc melting? Ensure HEA Chemical Homogeneity

- How is nitrogen handled in the vacuum quenching process? Optimize Your Heat Treatment with Precision

- Why is a vacuum oven essential for the degassing treatment of composite luminescent films? Ensure Optical Integrity

- What role does a vacuum sintering furnace play in fine ceramic component production? Achieve High-Purity, Dense Ceramics

- What are the key advantages of vacuum furnaces? Achieve Superior Heat Treatment for Your Materials

- What is the primary purpose of using a vacuum arc melting furnace for (AlTiV)100−xCrx alloys? Ensure Purity and Purity

- What are the main types of vacuum furnace chambers and their temperature ranges? Find the Perfect Fit for Your Lab