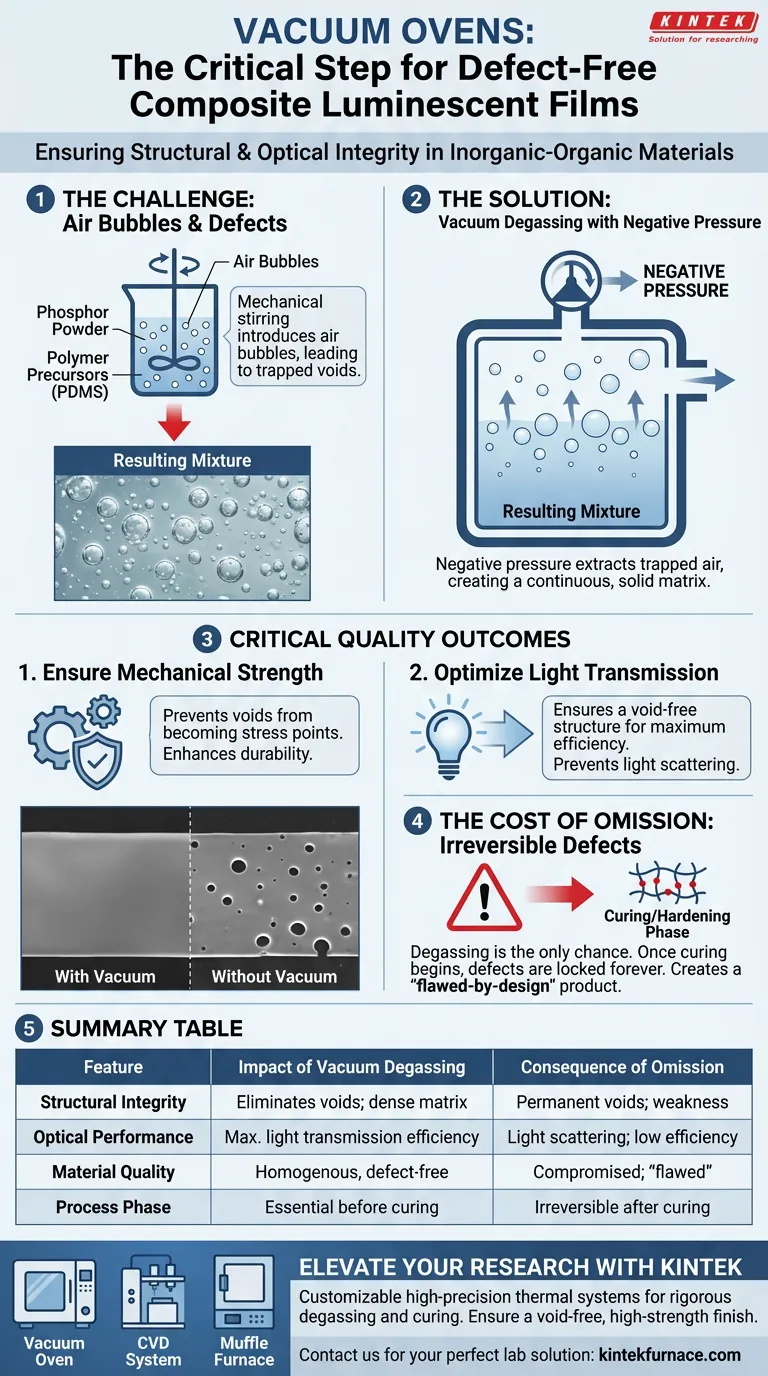

A vacuum oven is the critical mechanism for ensuring the structural and optical integrity of inorganic-organic composite films. During the preparation phase, specifically when mixing phosphor powder with polymer precursors like PDMS, microscopic air bubbles are inevitably trapped in the mixture. The vacuum oven utilizes negative pressure to forcefully extract these air pockets before the material sets.

Core Takeaway By eliminating air bubbles introduced during stirring, vacuum degassing prevents the formation of permanent internal voids. This step is non-negotiable for achieving the necessary mechanical strength and light transmission efficiency in the final luminescent film.

The Mechanics of Defect Prevention

The Challenge of Mixing

The preparation of composite films involves mechanically stirring phosphor powder into polymer precursors (such as PDMS). While necessary to create a homogenous mixture, this stirring process naturally introduces air into the viscous liquid. Without intervention, these microscopic bubbles remain suspended in the material.

The Role of Negative Pressure

The vacuum oven solves this problem by creating a negative pressure environment. This pressure differential causes the trapped air bubbles within the mixture to expand, rise to the surface, and escape. This process, known as degassing, creates a solid, continuous material matrix free of gas pockets.

Critical Quality Outcomes

Ensuring Mechanical Strength

If the vacuum treatment is skipped or performed poorly, the trapped air bubbles remain present during the curing and film-forming stages. As the polymer hardens, these bubbles turn into permanent internal voids. These voids act as structural flaws, significantly compromising the mechanical durability and strength of the final composite film.

Optimizing Light Transmission

For luminescent films, optical performance is paramount. The presence of voids or bubbles disrupts the material's uniformity. By using a vacuum oven to ensure a void-free structure, you guarantee maximum light transmission efficiency, allowing the composite material to function as intended without interference from internal defects.

The Cost of Omission

Permanent Structural Damage

It is vital to understand that the degassing phase is the only opportunity to remove these defects. Once the curing process begins, the polymer network cross-links and hardens. Any air remaining in the mixture at this point becomes permanently locked in, rendering the defect impossible to fix later.

Compromised Efficiency

Omitting the vacuum stage results in a product that is effectively "compromised by design." The resulting film will not only be physically weaker but will also fail to meet the efficiency standards required for high-performance applications due to the interference of air pockets with light propagation.

Making the Right Choice for Your Goal

To ensure your inorganic-organic composite films meet performance standards, prioritize the vacuum treatment based on your specific needs:

- If your primary focus is durability: Thoroughly degas the mixture to eliminate voids that act as stress concentrators and reduce mechanical strength.

- If your primary focus is optical performance: Use the vacuum oven to ensure a dense, bubble-free matrix that maximizes light transmission efficiency.

The vacuum oven is not merely a drying tool; it is the essential gatekeeper between a flawed mixture and a high-performance composite material.

Summary Table:

| Feature | Impact of Vacuum Degassing | Consequence of Omission |

|---|---|---|

| Structural Integrity | Eliminates voids; ensures dense matrix | Permanent internal voids; structural weakness |

| Optical Performance | Maximizes light transmission efficiency | Light scattering; decreased luminescence efficiency |

| Material Quality | Homogenous, defect-free composite | Compromised durability; "flawed-by-design" product |

| Process Phase | Essential before polymer curing/hardening | Irreversible defects once cross-linking begins |

Elevate Your Thin-Film Research with KINTEK

Don't let microscopic defects compromise your material's performance. Backed by expert R&D and manufacturing, KINTEK offers high-precision Vacuum, CVD, and Muffle furnace systems—all fully customizable to meet the rigorous degassing and curing requirements of your laboratory applications.

Whether you are working with PDMS-phosphor composites or advanced inorganic-organic materials, our specialized equipment ensures a void-free, high-strength finish every time.

Contact us today to find the perfect thermal solution for your lab!

Visual Guide

References

- Xin Pan, Rong‐Jun Xie. Quantifying the interfacial triboelectricity in inorganic-organic composite mechanoluminescent materials. DOI: 10.1038/s41467-024-46900-w

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is a vacuum furnace used? Achieve Superior Heat Treatment with Purity and Precision

- How does a vacuum oven assist in the infiltration of CsPbCl3 precursors into MSN? Optimize Your Nano-Infiltration

- Why must a vacuum system maintain a high vacuum during Al2O3-TiC sintering? Ensure Material Integrity & Density

- What is the significance of the thermal hysteresis temperature difference (Xth) in vacuum sintering? Control Heat Lag

- How do continuous furnaces demonstrate versatility in processing? Unlock Multi-Process Efficiency for High-Volume Manufacturing

- How is a directional solidification furnace used to remove metallic impurities from silicon? Achieve Solar-Grade Purity

- How is furnace brazing utilized in the medical and pharmaceutical industries? Ensure Sterile, Biocompatible Joints for Medical Devices

- What types of loads and configurations can vacuum furnaces handle? Explore Versatile Fixturing and Applications