In short, furnace brazing is a critical joining process used to manufacture high-integrity medical devices where failure is not an option. It is the preferred method for creating strong, sterile, and biocompatible joints in components ranging from surgical instruments and orthopedic implants to complex diagnostic equipment.

The core reason furnace brazing is indispensable in the medical field is its ability to produce exceptionally clean and hermetically sealed joints in a controlled vacuum environment. This process guarantees the sterility, biocompatibility, and structural reliability demanded by medical safety standards.

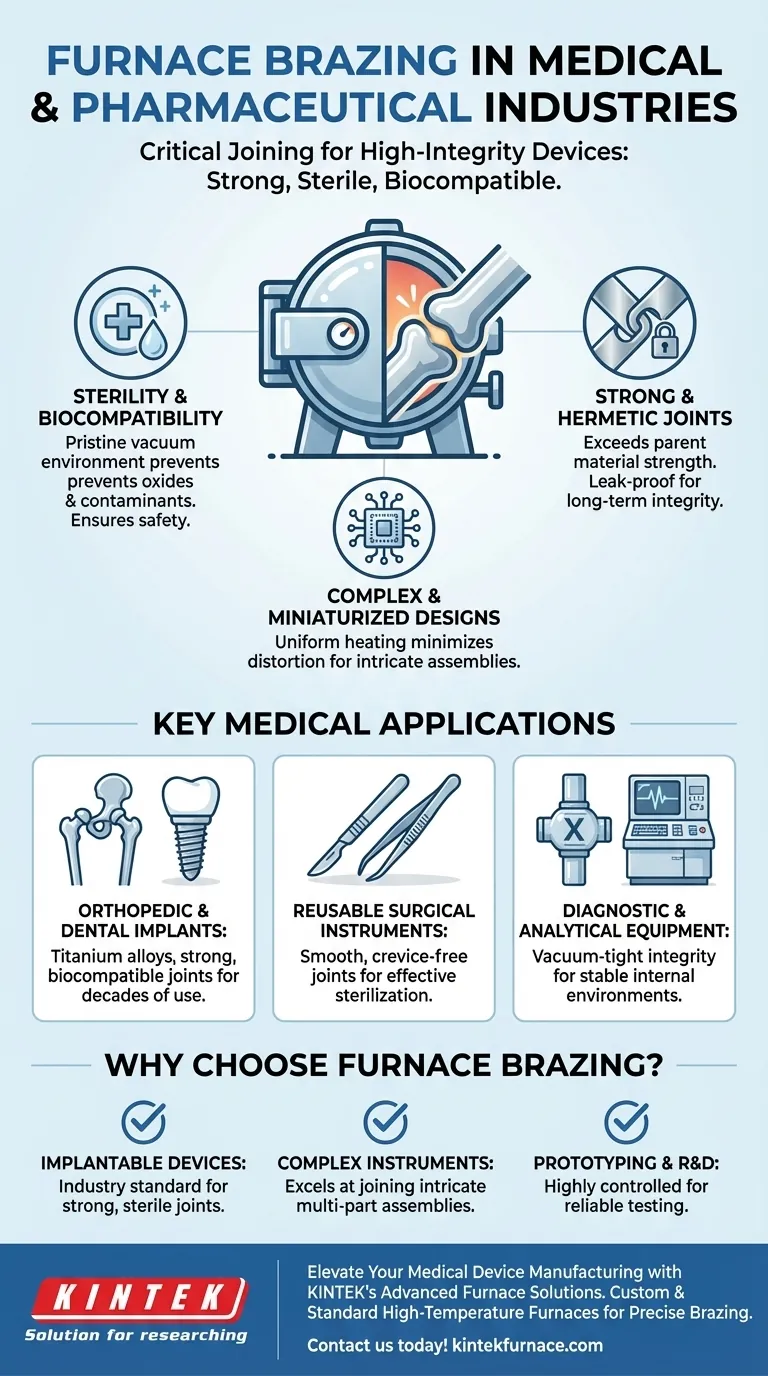

Why Furnace Brazing is Essential for Medical Devices

The choice of a manufacturing process for medical components is driven by safety, reliability, and performance. Furnace brazing excels in areas where other joining methods fall short.

Achieving Uncompromised Sterility and Biocompatibility

The defining feature of furnace brazing, particularly vacuum brazing, is the pristine environment it creates. By removing atmospheric gases, the process prevents the formation of oxides and other contaminants on the joint surfaces.

This is not a minor benefit; it is the primary reason the process is trusted for medical applications. A clean, oxide-free joint is inherently more biocompatible and ensures that no unwanted particulates can compromise the device's sterility or cause an adverse reaction in a patient.

Creating Strong and Hermetic Joints

Brazed joints are incredibly strong, often exceeding the strength of the parent materials being joined. The filler metal is drawn into the joint by capillary action, creating a complete, void-free bond.

This results in a hermetic seal, which is critical for many medical devices. For instance, enclosures for sensitive electronics in diagnostic equipment or sealed implants must be perfectly leak-proof to function correctly and safely over their intended lifespan.

Enabling Complex and Miniaturized Designs

Furnace brazing heats the entire assembly uniformly, minimizing the thermal stress and distortion that can occur with localized heating methods like welding.

This gentle, uniform heating allows engineers to design and join highly complex or delicate multi-part assemblies. It is essential for creating components like micro-channel heat exchangers used to cool sensitive medical device electronics or for assembling intricate surgical tools.

Key Applications in the Medical Field

The principles of cleanliness, strength, and design flexibility translate directly into a range of critical medical applications.

Orthopedic and Dental Implants

Furnace brazing is used to join materials like titanium alloys for orthopedic implants (e.g., hip or knee components) and dental posts. The resulting joints are strong enough to withstand decades of use and are biocompatible, preventing rejection by the body.

Reusable Surgical Instruments

Surgical instruments must be repeatedly sterilized at high temperatures. Brazed joints are smooth and free of the crevices or cracks found in mechanical assemblies, eliminating places where bacteria could hide. This ensures the instruments can be cleaned and sterilized effectively.

Diagnostic and Analytical Equipment

Complex machinery used for diagnostics, from X-ray tubes to analytical lab equipment, relies on components with vacuum-tight integrity. Furnace brazing is used to assemble these parts, ensuring the internal environments remain stable and free from contamination.

Understanding the Trade-offs and Considerations

While powerful, furnace brazing is a specialized process with specific requirements that make it suitable for some applications but not others.

Process Complexity and Cost

Furnace brazing is a batch process that requires significant capital investment in vacuum furnaces and precise process control. It is not as fast or inexpensive as simple soldering or welding, making it best suited for high-value components where performance is paramount.

Material Compatibility

The process involves heating entire assemblies to high temperatures. This means the parent materials must be able to withstand the brazing cycle without degrading. Careful material selection and filler metal choice are essential for success.

Focus on Devices, Not Pharmaceuticals

While your question included the pharmaceutical industry, furnace brazing is primarily used to build the equipment for the medical and pharmaceutical sectors, not in the direct manufacturing of drugs. It creates the bioreactors, sensors, and analytical instruments used in pharmaceutical research and production.

Making the Right Choice for Your Goal

To determine if furnace brazing is the right approach, consider your primary objective.

- If your primary focus is implantable devices: Furnace brazing is the industry standard for creating the strong, biocompatible, and sterile joints required for implants.

- If your primary focus is complex instruments or equipment: This process excels at joining intricate, multi-part assemblies and creating the hermetic seals needed for diagnostic and surgical tools.

- If your primary focus is prototyping new devices: Furnace brazing provides a highly controlled environment, making it an excellent choice for R&D and for testing new materials and designs reliably.

Ultimately, furnace brazing empowers engineers to build medical devices that meet the highest standards of safety, cleanliness, and long-term reliability.

Summary Table:

| Aspect | Key Details |

|---|---|

| Sterility & Biocompatibility | Prevents oxide formation and contaminants in vacuum environment, ensuring safe patient use. |

| Joint Strength & Hermetic Seal | Produces strong, leak-proof bonds that exceed parent material strength, critical for device integrity. |

| Design Flexibility | Enables complex, miniaturized assemblies with uniform heating, reducing thermal stress and distortion. |

| Key Applications | Orthopedic/dental implants, reusable surgical instruments, diagnostic equipment (e.g., X-ray tubes). |

| Considerations | Higher cost and complexity; best for high-value components; requires material compatibility and process control. |

Elevate Your Medical Device Manufacturing with KINTEK's Advanced Furnace Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements for medical and pharmaceutical applications.

Whether you're developing implantable devices, complex instruments, or diagnostic equipment, our furnaces ensure precise temperature control, uniform heating, and reliable performance for superior brazing outcomes. Contact us today to discuss how we can support your projects with tailored solutions that enhance safety, sterility, and efficiency!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement