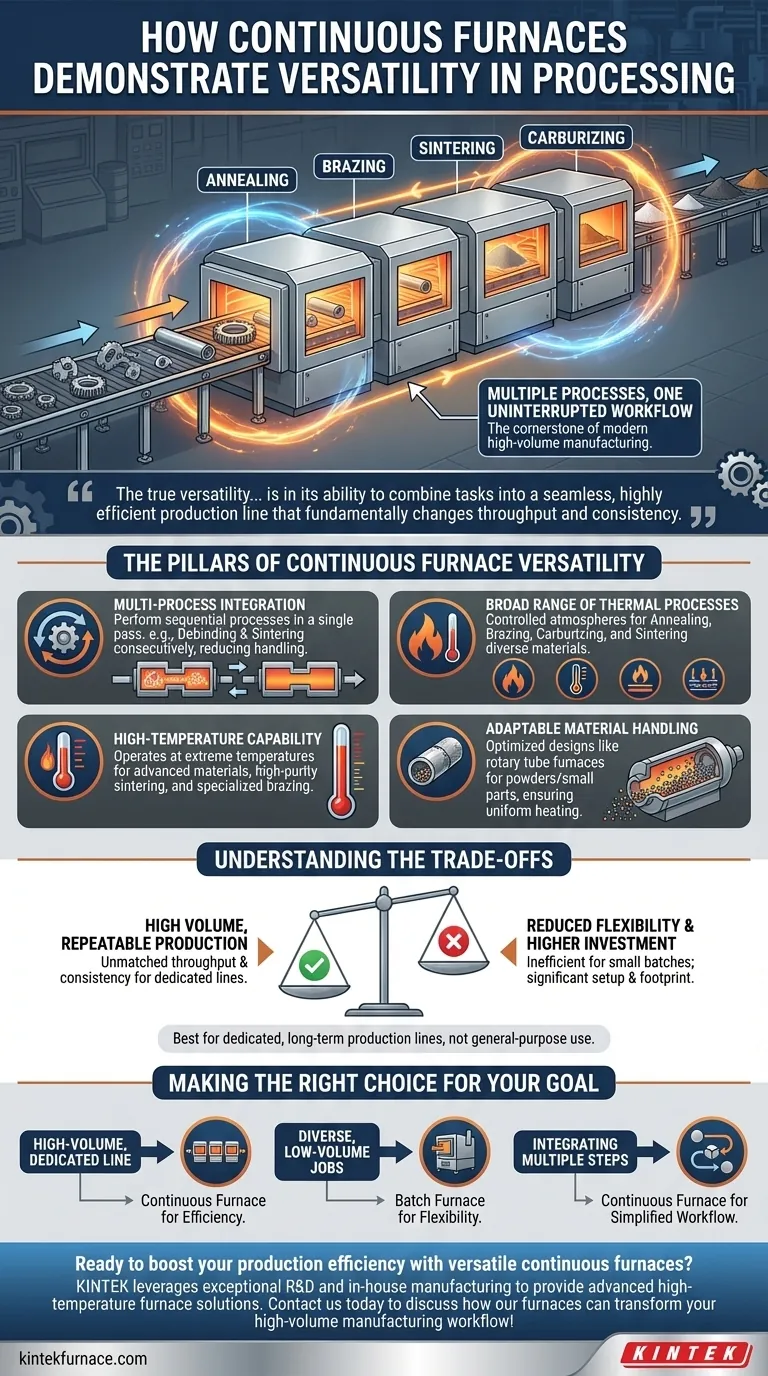

At their core, continuous furnaces demonstrate versatility by integrating multiple processes into a single, uninterrupted workflow. They are not just single-task machines but are engineered to handle a wide range of thermal treatments, from annealing and brazing to sintering, often at extremely high temperatures. This multi-function capability, combined with their design for constant operation, makes them a cornerstone of modern high-volume manufacturing.

The true versatility of a continuous furnace isn't just in the variety of tasks it can perform, but in its ability to combine those tasks into a seamless, highly efficient production line that fundamentally changes throughput and consistency.

The Pillars of Continuous Furnace Versatility

A continuous furnace's adaptability stems from a combination of its process capabilities, temperature range, and material handling design. Understanding these pillars is key to seeing why they are chosen for demanding industrial applications.

Multi-Process Integration

One of the most powerful features is the ability to perform multiple sequential processes in a single pass. For example, a part can move through different thermal zones within the same furnace.

This design allows for complex operations like debinding and sintering to occur consecutively without manual intervention, drastically reducing handling time and potential for error.

Broad Range of Thermal Processes

Continuous furnaces are not limited to a single type of heat treatment. Their controlled atmospheres and precise temperature zones make them suitable for a wide array of applications.

These processes include annealing, brazing, carburizing, and sintering, allowing a single furnace to serve diverse material treatment needs within a facility.

High-Temperature Capability

Many advanced materials and processes require extreme heat. Continuous furnaces are designed to meet this demand, often operating at temperatures approaching the melting point of the base metal.

This high-temperature performance is critical for applications like high-purity sintering or specialized brazing operations that are impossible in standard equipment.

Adaptable Material Handling

Versatility also comes from how materials move through the furnace. Different designs are optimized for different types of products.

For instance, rotary tube furnaces are ideal for powders or small parts, using rotation to ensure every surface is uniformly heated as material is transported continuously. This guarantees consistent processing for the entire production run.

Understanding the Trade-offs

While highly versatile for their intended purpose, continuous furnaces are not a universal solution. Their design creates specific operational trade-offs that must be considered.

Designed for High Volume, Not Small Batches

The primary strength of a continuous furnace is its ability to process a large volume of similar parts without stopping. This is also its main limitation.

They are inefficient for small, one-off jobs or prototype work, as the time and energy required to bring the furnace to a stable operating temperature for a short run is prohibitive.

Reduced Flexibility for Process Changes

Switching a continuous furnace from one process to another (e.g., from annealing steel to brazing copper) is a significant undertaking.

It requires changes to temperature profiles, atmospheric conditions, and belt speed, making it much less agile than a batch furnace, which can be reprogrammed for different jobs daily.

Higher Initial Investment and Footprint

Continuous furnaces are large, complex systems that represent a major capital investment. They also require significant floor space compared to smaller, more flexible batch furnaces.

This makes them a strategic choice for dedicated, long-term production lines rather than for general-purpose workshop use.

Making the Right Choice for Your Goal

The decision to use a continuous furnace is a strategic one tied directly to your production philosophy and operational scale.

- If your primary focus is high-volume, repeatable production: A continuous furnace offers unmatched throughput, consistency, and efficiency for a dedicated product line.

- If your primary focus is processing diverse, low-volume jobs: A batch furnace provides the necessary flexibility to change materials and processes frequently with lower operational overhead per job.

- If your primary focus is integrating multiple thermal steps: A continuous furnace's ability to combine processes into one seamless flow can dramatically simplify your manufacturing workflow and boost productivity.

Ultimately, choosing a continuous furnace is a commitment to a high-throughput, specialized production model.

Summary Table:

| Aspect | Key Details |

|---|---|

| Multi-Process Integration | Performs sequential processes like debinding and sintering in a single pass, reducing handling and errors. |

| Broad Thermal Processes | Supports annealing, brazing, carburizing, and sintering with controlled atmospheres and precise zones. |

| High-Temperature Capability | Operates at extreme temperatures for advanced materials, enabling high-purity sintering and specialized brazing. |

| Adaptable Material Handling | Designs like rotary tube furnaces ensure uniform heating for powders or small parts, enhancing consistency. |

| Trade-offs | Best for high-volume, dedicated lines; less efficient for small batches or frequent process changes. |

Ready to boost your production efficiency with versatile continuous furnaces? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental and production needs. Contact us today to discuss how our furnaces can transform your high-volume manufacturing workflow!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency