At its core, a vacuum furnace is used to perform high-temperature heat treatment processes in an environment free of air and other reactive gases. By removing the atmosphere, the furnace prevents unwanted chemical reactions like oxidation, resulting in finished parts with superior purity, strength, and surface quality compared to those processed in traditional furnaces.

The fundamental advantage of a vacuum furnace isn't just the heat it provides, but the controlled environment it creates. It solves the problem of material degradation and contamination that inevitably occurs when heating metals in the presence of air.

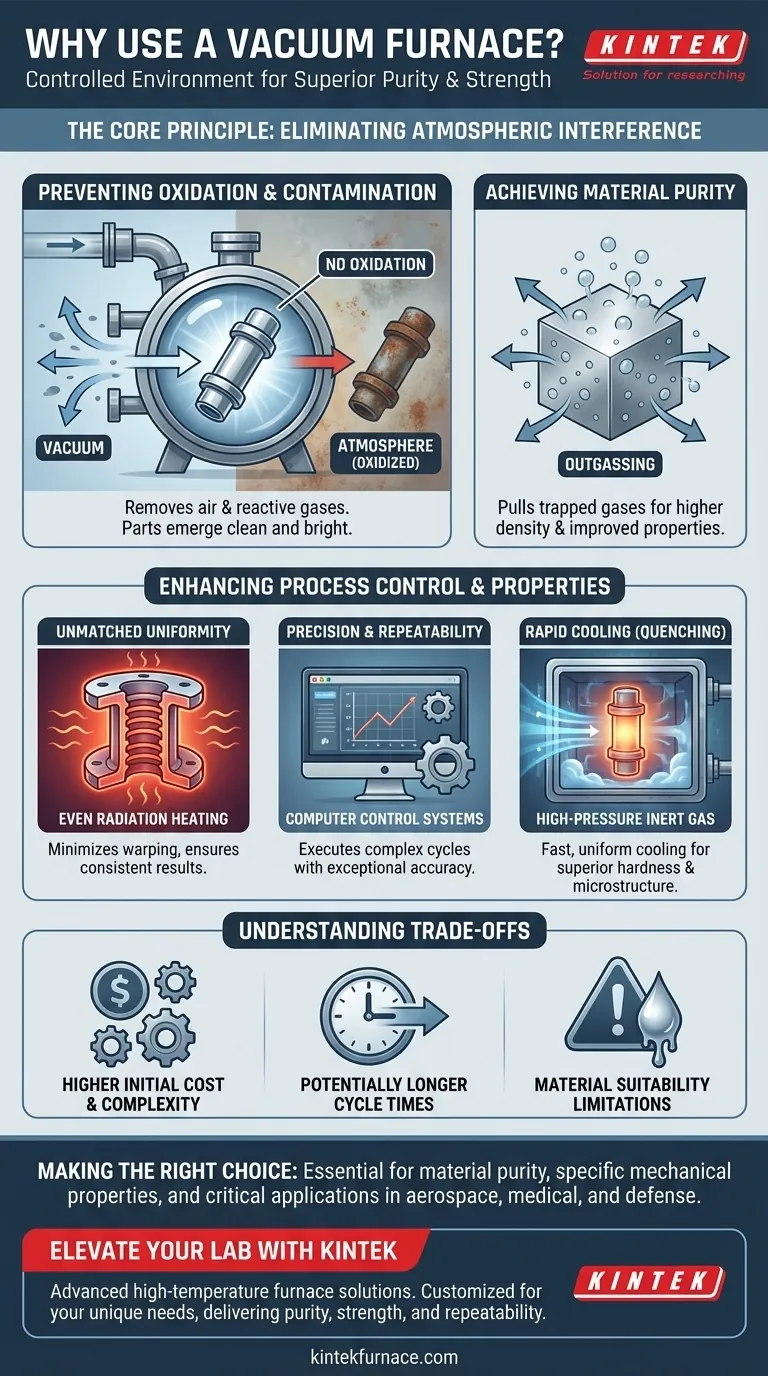

The Core Principle: Eliminating Atmospheric Interference

Heat treatment is transformative, but it also makes materials highly susceptible to their environment. A vacuum furnace directly controls this environment to achieve specific, high-purity outcomes.

Preventing Oxidation and Contamination

At high temperatures, most metals eagerly react with oxygen in the air, forming a layer of oxide scale. This scale is a form of contamination that can ruin a part's surface finish and even compromise its structural integrity.

A vacuum furnace physically removes the air—including oxygen, nitrogen, and water vapor—from the heating chamber. This prevents oxidation and ensures the part emerges from the process as clean and bright as when it went in.

Achieving Unmatched Material Purity

The vacuum environment doesn't just prevent contamination from the atmosphere; it also helps purify the material itself. The low-pressure environment effectively pulls trapped gases, like hydrogen and oxygen, out of the metal's internal structure.

This process, known as outgassing, results in a final product with higher density and improved mechanical and electrical properties.

Enhancing Process Control and Material Properties

Beyond creating a clean environment, vacuum furnaces offer a level of precision that is difficult to achieve with other methods. This control is critical for creating high-performance components.

Unmatched Temperature Uniformity

In a vacuum, heat transfer occurs primarily through radiation. This allows for extremely uniform heating, even on parts with complex geometries.

This uniformity minimizes the risk of warping or distortion and ensures that the entire part receives the exact same thermal treatment, leading to consistent metallurgical properties throughout.

Precision and Repeatability

Modern vacuum furnaces are managed by sophisticated computer control systems. These systems can execute highly complex, multi-stage heating and cooling cycles with exceptional accuracy.

This ensures that every part in a batch, and every batch over time, is processed identically. This metallurgical repeatability is non-negotiable in critical industries like aerospace, medical, and defense.

Rapid Cooling (Quenching)

After heating, many processes require the material to be cooled rapidly to lock in desired properties like hardness. Vacuum furnaces achieve this by back-filling the chamber with a high-pressure, inert gas (like nitrogen or argon).

This gas quenching process is extremely fast and uniform, providing superior control over the final microstructure of the material compared to quenching in liquids like oil or water.

Understanding the Trade-offs

While powerful, vacuum furnaces are not the universal solution for all heat-treating needs. Understanding their limitations is key to making an informed decision.

Higher Initial Cost and Complexity

Vacuum furnaces are sophisticated machines involving vacuum pumps, robust chamber seals, and advanced control systems. This results in a higher initial investment and more complex maintenance requirements compared to standard atmospheric furnaces.

Potentially Longer Cycle Times

The process of pumping the chamber down to the required vacuum level adds time to each cycle. For simple processes on non-reactive materials, an atmospheric furnace may offer faster throughput.

Material Suitability

Certain materials with a high vapor pressure (like zinc, magnesium, or cadmium) can vaporize under a deep vacuum at high temperatures. This can contaminate the furnace and damage the part, making them unsuitable for some vacuum processes.

Making the Right Choice for Your Application

Choosing the right furnace technology depends entirely on the material you are processing and the final properties you need to achieve.

- If your primary focus is material purity and preventing oxidation: A vacuum furnace is essential for reactive metals like titanium and superalloys, or for achieving a bright, clean finish without secondary cleaning operations.

- If your primary focus is achieving specific, repeatable mechanical properties: The precision temperature and quenching control of a vacuum furnace is critical for high-performance applications in aerospace, medical devices, and tooling.

- If your primary focus is brazing or joining complex assemblies: The clean, flux-free environment of a vacuum furnace creates stronger, more reliable, and void-free joints that are impossible to achieve otherwise.

- If your primary focus is low-cost, bulk heat treatment of simple carbon steels: A traditional atmospheric furnace is often the more practical and cost-effective solution.

Ultimately, a vacuum furnace is the definitive tool when absolute control over the processing environment is required to achieve superior material outcomes.

Summary Table:

| Key Aspect | Benefit |

|---|---|

| Oxidation Prevention | Eliminates air and reactive gases for clean, bright parts without contamination. |

| Material Purity | Removes trapped gases via outgassing, improving density and mechanical properties. |

| Temperature Uniformity | Uses radiation for even heating, reducing warping and ensuring consistent properties. |

| Process Control | Computer systems enable precise, repeatable cycles for reliable metallurgical outcomes. |

| Rapid Cooling | Gas quenching provides fast, uniform cooling for enhanced material hardness and microstructure. |

Elevate your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, delivering superior purity, strength, and repeatability for critical applications in aerospace, medical, and more. Contact us today to discuss how we can optimize your heat treatment processes and drive innovation in your projects!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability