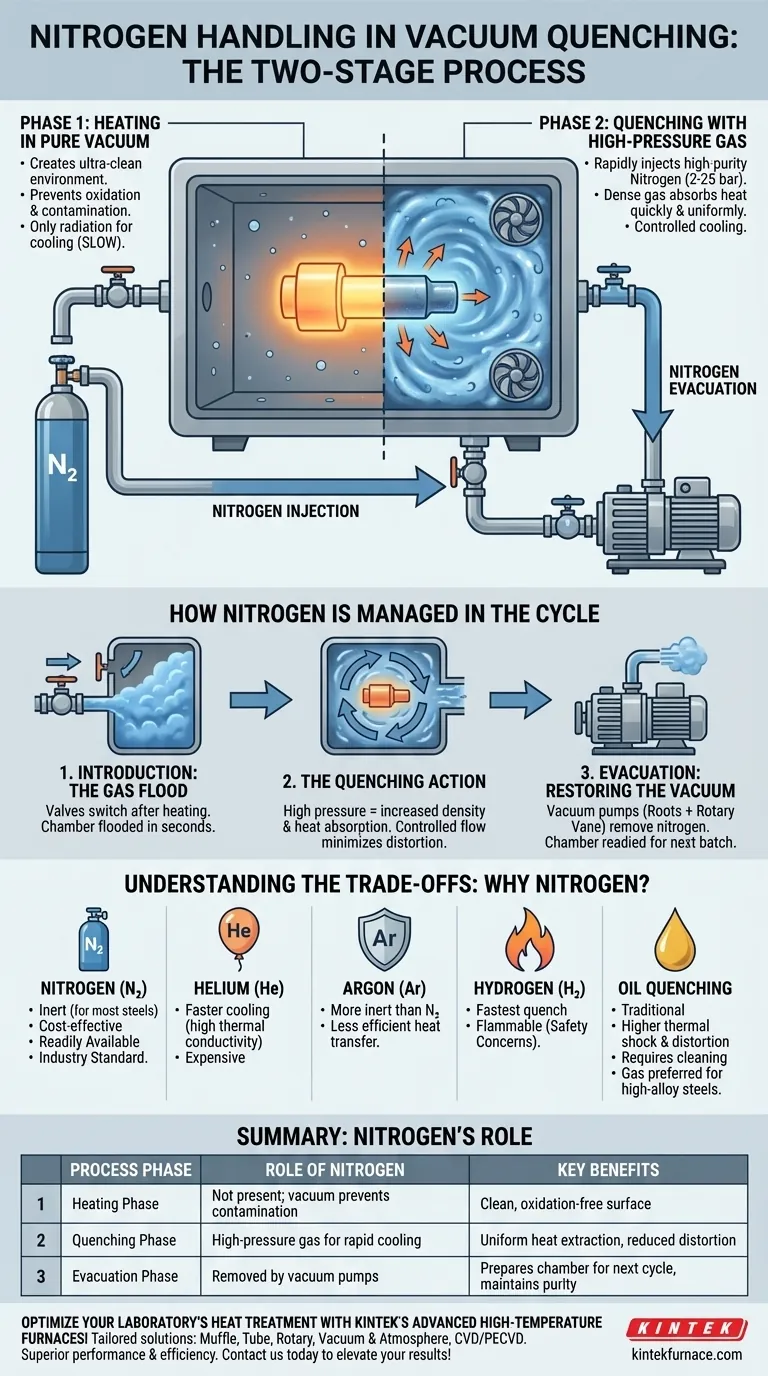

In vacuum quenching, nitrogen is not part of the vacuum; it is the high-pressure gas used to perform the actual cooling. The term "vacuum quenching" can be misleading. The process involves heating the material in a pristine vacuum to prevent contamination and then rapidly introducing nitrogen gas to cool, or "quench," the part. Once the quench is complete, the nitrogen is evacuated from the chamber by the vacuum pump system.

The core concept is a two-stage process. First, a vacuum creates an ultra-clean environment for heating. Second, high-pressure nitrogen is used as a tool for rapid, controlled cooling—a task that is impossible in a vacuum alone. The "handling" of nitrogen involves its controlled injection and subsequent removal.

The Two-Phase Quenching Process

A vacuum furnace performs two distinct and opposite functions to achieve the final material properties. Understanding this duality is key to understanding nitrogen's role.

Phase 1: Heating in a Pure Vacuum

The initial stage involves placing the metal part inside a sealed chamber and removing all the air and other atmospheric gases.

This vacuum environment is critical because it prevents oxidation and other surface reactions that would occur if the part were heated in air. The result is a bright, clean part with no surface contamination.

Phase 2: Quenching with High-Pressure Gas

Cooling a part in a vacuum is extremely slow, as heat can only dissipate through radiation. To achieve the rapid cooling needed for hardening (quenching), a transfer medium is required.

This is where nitrogen comes in. After the part is fully heated, the furnace rapidly injects high-purity nitrogen, often at pressures from 2 to 25 bar. Powerful fans then circulate this dense gas, forcing it over the hot part to extract heat quickly and uniformly.

How Nitrogen is Managed in the Cycle

The handling of nitrogen is a precise, automated sequence designed for maximum efficiency and control.

Introduction: The Gas Flood

Once the material reaches its target austenitizing temperature, the system's valves switch. The vacuum pumps are isolated, and valves connected to a high-pressure nitrogen supply are opened. The chamber is flooded with nitrogen in a matter of seconds.

The Quenching Action

The high pressure of the nitrogen increases its density, which dramatically improves its ability to absorb and carry away heat from the metal. The speed and pressure of the nitrogen flow are carefully controlled to manage the cooling rate and minimize part distortion.

Evacuation: Restoring the Vacuum

After the part has been cooled to the target temperature, the nitrogen has served its purpose. The furnace's powerful vacuum pump system, typically a combination of a Roots pump and a rotary vane pump, is re-engaged.

This system pumps all the nitrogen gas out of the chamber, re-establishing a medium vacuum (down to around 1 mbar). The chamber is then ready for the next batch or the part can be removed.

Understanding the Trade-offs: Why Nitrogen?

Nitrogen is the most common gas for vacuum quenching, but it's not the only option. The choice involves balancing performance, cost, and material compatibility.

The Benefits of Nitrogen

Nitrogen is the industry workhorse because it provides an excellent balance of properties. It is largely inert, preventing reactions with most steels, and is significantly more cost-effective and readily available than other options.

Alternatives to Nitrogen

Other gases like helium, argon, and hydrogen are used for specific applications. Helium provides a faster cooling rate due to its high thermal conductivity but is much more expensive. Argon is more inert than nitrogen but less efficient at heat transfer. Hydrogen offers the fastest quench but is flammable and requires extensive safety systems.

Gas vs. Oil Quenching

The main alternative to gas quenching is traditional oil quenching. Gas quenching is preferred for high-alloy steels like high-speed tool steels because it produces less thermal shock and distortion. This results in cleaner parts with more predictable dimensions and no need for post-quench cleaning.

Making the Right Choice for Your Goal

The selection of a quenching medium is dictated by the alloy being treated and the desired final properties.

- If your primary focus is cost-effective hardening of common tool steels: Nitrogen is the industry standard, offering a superb balance of performance, safety, and economy.

- If your primary focus is the fastest possible quench for sensitive alloys: Helium or hydrogen may be required, but you must account for significantly higher operational costs and safety protocols.

- If your primary focus is quenching highly reactive metals at high temperatures: Argon provides the most inert environment, protecting against any potential nitride formation, though at the cost of a slower quench rate.

Ultimately, handling nitrogen in a vacuum furnace is a controlled cycle of injection and evacuation that leverages the purity of a vacuum and the cooling power of a gas.

Summary Table:

| Process Phase | Role of Nitrogen | Key Benefits |

|---|---|---|

| Heating Phase | Not present; vacuum prevents contamination | Clean, oxidation-free surface |

| Quenching Phase | High-pressure gas for rapid cooling | Uniform heat extraction, reduced distortion |

| Evacuation Phase | Removed by vacuum pumps | Prepares chamber for next cycle, maintains purity |

Optimize your laboratory's heat treatment processes with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering superior performance and efficiency. Contact us today to discuss how our expertise can elevate your results!

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- How do vacuum furnaces contribute to long-term cost savings? Reduce Costs with Efficiency and Quality

- Why might a vacuum furnace maintain vacuum during cooling? Protect Workpieces from Oxidation and Control Metallurgy

- What role does a vacuum sintering furnace play in the formation of the 'core-rim' structure in Ti(C,N)-FeCr cermets?

- How are parts loaded into a vacuum furnace? Ensure Precision and Efficiency in Your Process