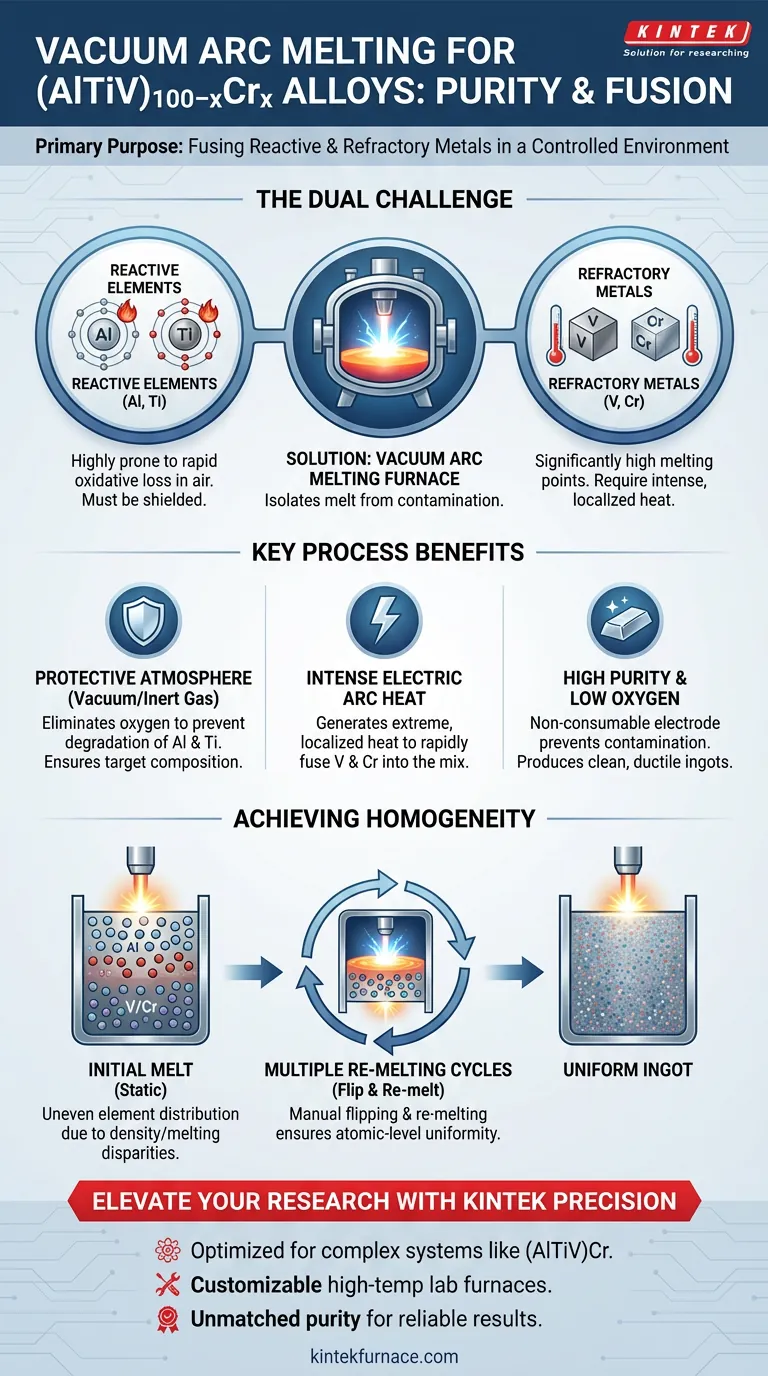

The primary purpose of using a vacuum arc melting furnace for (AlTiV)100−xCrx alloys is to generate the intense, localized heat required to melt refractory metals like vanadium and chromium while maintaining a strictly controlled environment to prevent the degradation of reactive elements.

Specifically, this process uses a vacuum or inert gas atmosphere to eliminate oxygen, which is critical for preventing the rapid oxidative loss of aluminum and titanium. This ensures the final ingot retains its intended chemical composition and achieves high purity.

Core Takeaway The vacuum arc melting furnace solves the dual challenge of fusing high-melting-point metals (V, Cr) without destroying highly reactive components (Al, Ti). It serves as the fundamental tool for producing low-oxygen, high-purity ingots by isolating the melt from atmospheric contamination.

The Critical Role of Environment and Heat

Preventing Oxidative Loss

The (AlTiV)100−xCrx system contains aluminum (Al) and titanium (Ti). These elements are classified as "active" metals.

If exposed to oxygen at melting temperatures, Al and Ti will oxidize almost instantly. This results in "oxidative loss," where the actual amount of useful metal in the alloy drops below the target composition.

The vacuum arc furnace mitigates this by operating under a high vacuum or a protective inert gas atmosphere (such as argon). This environment effectively shields the active elements, ensuring they remain metallic rather than turning into brittle oxide impurities.

Overcoming High Melting Points

This specific high-entropy alloy includes vanadium (V) and chromium (Cr). These metals have significantly higher melting points than aluminum.

Standard furnaces often struggle to melt these refractory elements quickly enough to prevent the lower-melting elements from evaporating.

The electric arc generates extreme, localized high heat. This allows for the rapid fusion of the entire mix—Al, Ti, V, and Cr—ensuring the high-melting-point components are fully integrated into the liquid melt.

Ensuring Purity and Quality

The Role of Non-Consumable Electrodes

To achieve a "high-purity" ingot, it is vital to avoid introducing foreign materials during the melting process.

Vacuum arc furnaces typically employ non-consumable electrodes (often tungsten). Because the electrode itself does not melt into the pool, it eliminates a common source of contamination found in other melting methods.

Achieving Low-Oxygen Ingots

Oxygen is the enemy of ductility in high-entropy alloys. High oxygen content often leads to the formation of brittle impurity phases.

By combining the vacuum environment with the non-consumable electrode design, the furnace produces ingots with exceptionally low oxygen levels. This provides a clean baseline for studying the alloy's mechanical properties.

Understanding the Trade-offs

While the vacuum arc melting furnace is excellent for purity and heat generation, it presents a challenge regarding homogeneity.

The Homogeneity Challenge

Unlike induction melting, which naturally stirs the metal electromagnetically, arc melting is a more static process.

Simply melting the components once often results in an uneven distribution of elements, especially when there is a disparity in density and melting points between Al (light, low melt) and V/Cr (heavy, high melt).

The Necessity of Re-melting

To solve the homogeneity issue, the process requires multiple melting cycles.

Operators must flip (invert) the ingot and re-melt it several times. This manual intervention is required to ensure an atomic-level uniform distribution of elements throughout the alloy. Without this step, the ingot may have segregated regions, rendering performance data unreliable.

Making the Right Choice for Your Goal

To maximize the quality of your (AlTiV)100−xCrx alloy, you must tailor your procedure to the furnace's capabilities.

- If your primary focus is Compositional Accuracy: strictly control the vacuum or inert gas pressure to prevent the volatilization or oxidation of Aluminum and Titanium.

- If your primary focus is Microstructural Uniformity: Mandate multiple re-melting cycles (flipping the ingot) to compensate for the lack of electromagnetic stirring.

By leveraging the high heat and protective atmosphere of the vacuum arc furnace, you establish the essential foundation for a high-performance, lightweight high-entropy alloy.

Summary Table:

| Feature | Benefit for (AlTiV)100−xCrx Alloys |

|---|---|

| Vacuum/Inert Atmosphere | Prevents oxidative loss of reactive Aluminum and Titanium |

| High-Intensity Electric Arc | Rapidly melts high-melting-point refractory metals (V, Cr) |

| Non-Consumable Electrode | Eliminates contamination for high-purity ingot production |

| Multiple Re-melting Cycles | Overcomes homogeneity challenges for uniform element distribution |

| Low Oxygen Environment | Enhances ductility by reducing brittle oxide phase formation |

Elevate Your Alloy Research with KINTEK Precision

Achieving the perfect balance of purity and homogeneity in high-entropy alloys requires world-class equipment. KINTEK provides industry-leading vacuum arc melting systems, muffle furnaces, and CVD systems designed to handle reactive and refractory metals with ease.

Why choose KINTEK?

- Expert R&D: Optimized for complex alloy systems like (AlTiV)Cr.

- Customizable Solutions: Tailored high-temp lab furnaces for unique material needs.

- Unmatched Purity: Engineered to minimize oxygen contamination and maximize performance.

Ready to refine your melting process? Contact our technical experts today to find the ideal furnace for your laboratory.

Visual Guide

References

- Corrosion-Wear Mechanism of (AlTiV)100−xCrx Lightweight High-Entropy Alloy in the 3.5 wt.% NaCl Solution. DOI: 10.3390/ma18112670

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the primary functions of a vacuum furnace? Achieve Superior Material Processing in a Controlled Environment

- What is the critical function of the water-cooled lid and body in a vacuum furnace during the magnesium distillation process?

- What are the advantages of high vacuum furnaces? Achieve Ultimate Purity and Control

- What is the primary function of vacuum furnace annealing for ZnS nanopowders? Achieve High-Purity Ceramic Performance

- What role does a vacuum oven play in delta-MnO2 electrode processing? Stabilize and Protect Your Active Materials

- How do vacuum furnaces contribute to long-term cost savings? Reduce Costs with Efficiency and Quality

- Why is the cooling system important in the furnace? Ensure Longevity, Efficiency, and Safety

- Why is vacuum distillation equipment necessary for the purification of aluminum isopropoxide colloids?