At its core, a high vacuum furnace offers one fundamental advantage: absolute control over the processing environment. By removing air and other atmospheric gases, these furnaces prevent unwanted chemical reactions like oxidation, enabling the creation of materials with superior properties, pristine surface finishes, and a level of purity unattainable in conventional furnaces.

The decision to use a high vacuum furnace is not about incremental improvement; it is about enabling metallurgical outcomes that are impossible in a standard atmosphere. It is a choice driven by the need for ultimate material purity and process control, especially when working with sensitive or high-performance materials.

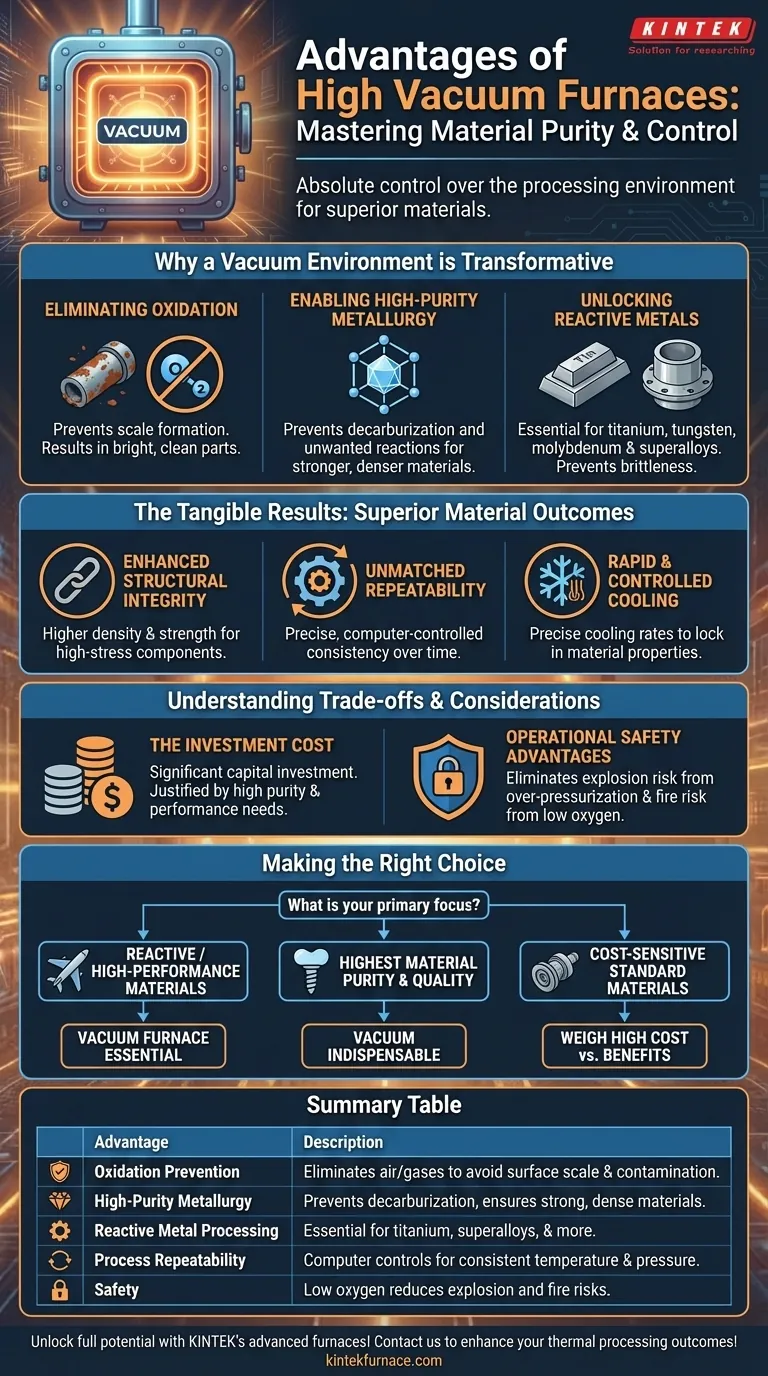

Why a Vacuum Environment is Transformative

The primary function of the vacuum is not the vacuum itself, but what it removes: reactive gases. This creates a uniquely stable environment for high-temperature thermal processes.

Eliminating Contamination and Oxidation

At high temperatures, most metals will readily react with oxygen in the air. This reaction, known as oxidation, forms a layer of scale on the material's surface, which compromises both its finish and its structural integrity.

A vacuum furnace evacuates nearly all the air, preventing oxidation and other forms of contamination from gases like nitrogen or water vapor. This results in bright, clean parts straight out of the furnace.

Enabling High-Purity Metallurgy

Beyond oxidation, the controlled atmosphere prevents decarburization and other unwanted surface reactions that can alter a material's chemical composition and mechanical properties.

This allows for processes like brazing and sintering where the purity of the joints and the final material density are critical for performance. The resulting components are stronger, denser, and more reliable.

Unlocking Reactive Metal Processing

Some of the most advanced materials, including titanium, tungsten, molybdenum, and superalloys, are highly reactive. Exposing them to oxygen at high temperatures would be catastrophic, rendering them brittle and useless.

A high vacuum furnace is often the only viable technology for heat-treating these materials, making it indispensable for industries like aerospace, medical, and advanced electronics.

The Tangible Results: Superior Material Outcomes

The pristine environment of a vacuum furnace translates directly into measurable improvements in the final product.

Enhanced Structural Integrity

By preventing the inclusion of oxides and other impurities, materials processed in a vacuum achieve higher density and strength. This is crucial for high-stress components where performance and reliability are non-negotiable.

Unmatched Process Repeatability

Modern vacuum furnaces are equipped with sophisticated computer controls. This allows for precise and repeatable management of temperature (often up to 2200°C), pressure levels, and cooling rates.

This metallurgical repeatability ensures that every part in a batch, and every batch over time, meets the exact same high standard.

Rapid and Controlled Cooling

Many systems incorporate rapid gas quenching capabilities. This allows for precise control over the cooling cycle, which is a critical phase of heat treatment for locking in desired material properties like hardness and grain structure.

Understanding the Trade-offs and Considerations

While powerful, a vacuum furnace is a specialized tool with specific considerations. An objective evaluation is key.

The Investment Cost

The primary drawback is cost. High vacuum furnaces represent a significant capital investment compared to conventional atmosphere furnaces. Their complexity, including vacuum pumps and advanced controls, drives up the initial price.

This technology is typically justified when the material requirements for purity and performance outweigh the higher initial expense.

Operational Safety Advantages

Unlike furnaces operating at positive pressure, a vacuum furnace inherently eliminates the risk of explosion from over-pressurization.

Furthermore, the extremely low oxygen content virtually removes the risk of fire from the oxidation of materials inside the chamber, making it a safer operational environment.

Making the Right Choice for Your Application

Selecting the right thermal processing technology depends entirely on your material, your process, and your final goal.

- If your primary focus is processing reactive or high-performance materials (superalloys, titanium): A vacuum furnace is essential and often the only technology capable of meeting your requirements.

- If your primary focus is achieving the highest material purity and surface quality: The contamination control provided by a vacuum is indispensable for applications like medical implants or aerospace brazing.

- If your primary focus is cost-sensitive production of standard materials: You must carefully weigh the high initial cost against the benefits of eliminating post-processing steps and achieving higher part-to-part consistency.

Ultimately, choosing a vacuum furnace is an investment in process control and material perfection.

Summary Table:

| Advantage | Description |

|---|---|

| Oxidation Prevention | Eliminates air and gases to avoid surface scale and contamination. |

| High-Purity Metallurgy | Prevents decarburization and ensures strong, dense materials. |

| Reactive Metal Processing | Essential for heat-treating titanium, superalloys, and more. |

| Process Repeatability | Computer controls for consistent temperature and pressure management. |

| Safety | Low oxygen content reduces explosion and fire risks. |

Unlock the full potential of your materials with KINTEK's advanced high vacuum furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide tailored solutions for diverse laboratories, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, delivering superior purity, control, and reliability. Contact us today to discuss how we can enhance your thermal processing outcomes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today