At a glance, the main types of vacuum furnace chambers, more accurately called "hot zones," are constructed from stainless steel, ceramic fiber, molybdenum, or graphite. These materials dictate the furnace's capabilities, with maximum operating temperatures ranging from approximately 750°C for basic steel designs to over 2200°C for advanced graphite systems.

The choice of a vacuum furnace chamber is not just about hitting a target temperature. It is a critical decision that impacts process purity, operational cost, and the chemical compatibility with the material you are processing. Understanding the hot zone material is key to matching the furnace to your specific application.

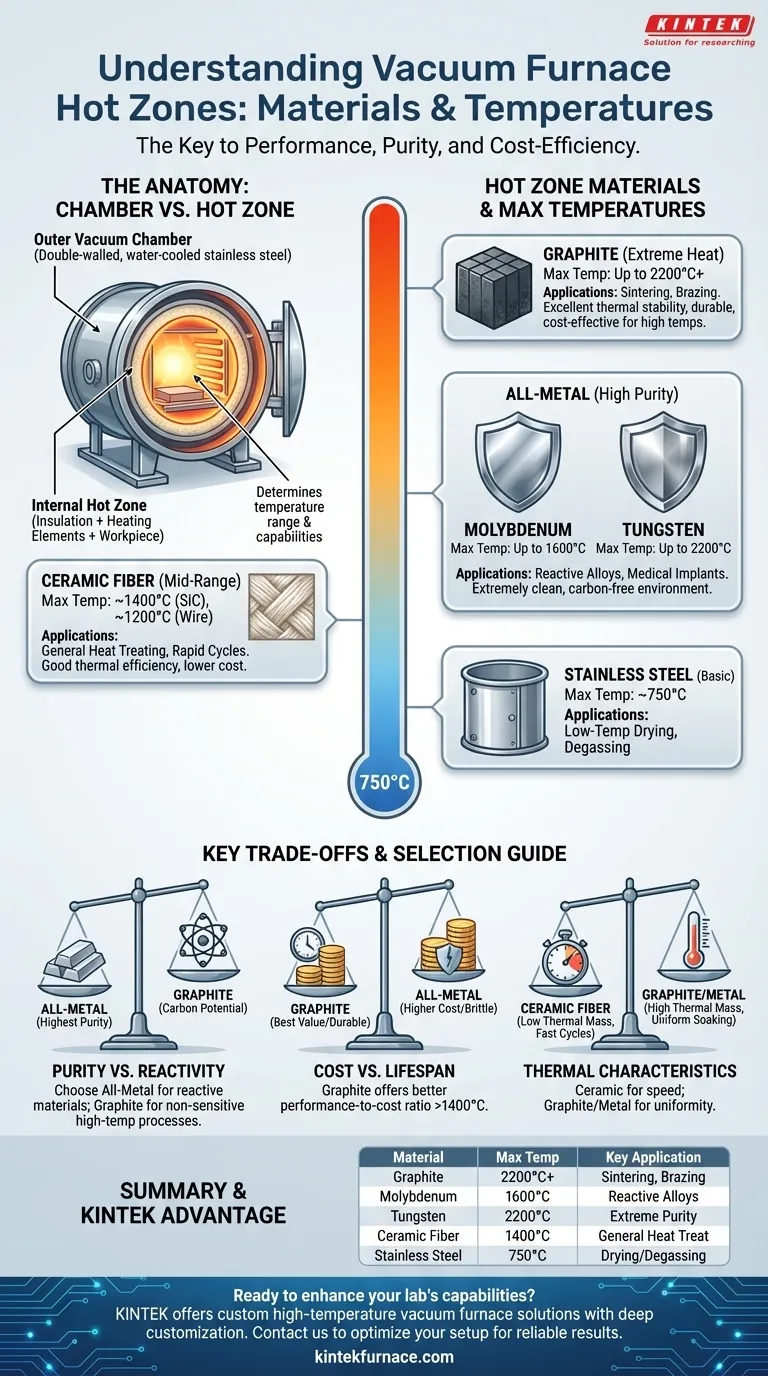

The Anatomy of a Vacuum Furnace: Chamber vs. Hot Zone

It is crucial to distinguish between the outer vacuum chamber and the internal "hot zone." The term "chamber" is often used interchangeably, which can cause confusion.

The Outer Vacuum Chamber

The external vessel is almost always made of double-walled, water-cooled stainless steel. Its job is to contain the vacuum and remain cool and stable on the outside, regardless of the extreme temperatures within.

The Internal Hot Zone

The hot zone is the insulated interior where the heating elements and the workpiece reside. The material used to construct this hot zone is what truly defines the furnace's temperature range and process capabilities.

A Breakdown of Hot Zone Materials and Temperatures

The material of the hot zone—its insulation and heating elements—determines the furnace's performance characteristics.

All-Metal Hot Zones (Molybdenum & Tungsten)

All-metal hot zones use reflective shields made of metals like molybdenum or tungsten as insulation. They are renowned for creating an extremely clean, high-vacuum environment.

These are ideal for processing highly sensitive materials where any contamination, especially from carbon, must be avoided. Heating elements are typically made of the same material (molybdenum or tungsten).

- Typical Max Temperature (Molybdenum): Up to 1600°C

- Typical Max Temperature (Tungsten): Up to 2200°C

Graphite Hot Zones

Graphite is the workhorse for very high-temperature applications. It can be rigid felt or composite board, offering excellent thermal stability and structural integrity at extreme heat.

Because graphite is the heating element and the insulation, these furnaces can reach very high temperatures cost-effectively. They are exceptionally durable and resistant to thermal shock.

- Typical Max Temperature: Up to 2200°C (and higher in some designs)

Ceramic Fiber Hot Zones

These furnaces use blankets or boards made of ceramic fiber for insulation. They are common in lower-temperature vacuum applications and air-firing furnaces.

Heating elements are typically metallic heating wires (like Kanthal) or silicon carbide (SiC) rods. This construction offers good thermal efficiency at a lower cost.

- Typical Max Temperature (Heating Wires): ~1200°C

- Typical Max Temperature (SiC Elements): ~1400°C

Understanding the Trade-offs

Choosing a hot zone material involves balancing performance, cost, and process compatibility. There is no single "best" option.

Purity vs. Reactivity

An all-metal hot zone offers the highest purity. It is essential for processing reactive metals like titanium or medical implants.

A graphite hot zone is excellent for most brazing and sintering, but the carbon atmosphere can react with certain materials. It is unsuitable if carbon pickup is a concern but can be beneficial for processing carbides.

Cost and Lifespan

Graphite furnaces generally offer the best performance-to-cost ratio for temperatures above 1400°C. The components are robust but can be brittle.

All-metal hot zones are significantly more expensive. The metallic shields can become brittle after repeated thermal cycles and may require careful handling and eventual replacement.

Thermal Characteristics

Ceramic fiber insulation has a very low thermal mass, allowing for faster heating and cooling cycles compared to graphite or all-metal designs.

Graphite and metal hot zones have higher thermal mass, meaning they heat and cool more slowly but provide excellent temperature uniformity for soaking applications.

Selecting the Right Furnace for Your Application

Your final choice depends entirely on your process goals. Use these guidelines to make an informed decision.

- If your primary focus is high-purity processing of reactive alloys: Choose an all-metal (molybdenum or tungsten) hot zone to guarantee a clean, carbon-free environment.

- If your primary focus is high-temperature sintering or brazing: A graphite hot zone delivers the best high-temperature performance and durability for the cost.

- If your primary focus is general-purpose heat treating or annealing below 1200°C: A ceramic fiber insulated furnace provides a versatile and cost-effective solution with rapid cycle times.

- If your primary focus is simply low-temperature drying or degassing: A basic vacuum oven with an uninsulated stainless steel chamber is often sufficient and cost-effective.

Matching the hot zone material to your specific process requirements is the fundamental principle for achieving reliable and repeatable results in vacuum processing.

Summary Table:

| Hot Zone Material | Max Temperature Range | Key Applications |

|---|---|---|

| Graphite | Up to 2200°C | High-temperature sintering, brazing |

| Molybdenum | Up to 1600°C | High-purity processing of reactive alloys |

| Tungsten | Up to 2200°C | Extreme high-purity applications |

| Ceramic Fiber | Up to 1400°C | General-purpose heat treating, rapid cycles |

| Stainless Steel | Up to 750°C | Low-temperature drying, degassing |

Ready to enhance your lab's capabilities with a custom vacuum furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by deep customization to ensure precise performance for applications like sintering, brazing, and high-purity processing. Contact us today to discuss how we can optimize your vacuum furnace setup for reliable, repeatable results!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the main application areas of vacuum annealing furnaces? Essential for High-Purity Material Processing

- What are the environmental advantages of vacuum furnaces? Reduce Emissions and Energy Use

- What is Age Hardening in vacuum heat treating? Unlock Peak Metal Performance with Precision

- What is the function of a laboratory vacuum drying oven in carbon nitride catalyst processing? Ensure Optimal Performance

- What are the advantages of vacuum heat treatment furnaces? Achieve Superior Process Control and Purity

- How does the vacuum sintering furnace operate for sintering hard metals and alloys? Achieve High-Density, Pure Materials

- How do vacuum chambers and heating systems prepare zirconium alloy samples? Achieving Precise Hydrogen Concentration

- Why are vacuum furnaces important in aerospace? Essential for High-Strength, Pure Components