At its core, a vacuum sintering furnace is the technology that enables the production of high-purity, high-density fine ceramic components. It performs an integrated degreasing and sintering process within a single, highly controlled vacuum environment. This prevents oxidation and contamination from atmospheric gases, which is critical for achieving the superior physical and mechanical properties required in materials like silicon nitride, aluminum nitride, and high-purity oxides.

The fundamental challenge in creating advanced ceramics is that heating them in air introduces impurities and causes unwanted chemical reactions. A vacuum sintering furnace solves this by removing the atmosphere, allowing materials to be fused together based purely on heat and their intrinsic properties, resulting in a cleaner, stronger final component.

How Vacuum Sintering Transforms Ceramic Production

The decision to use a vacuum furnace is not about incremental improvement; it is about enabling a different class of material performance. It fundamentally changes what is possible during the high-temperature consolidation phase.

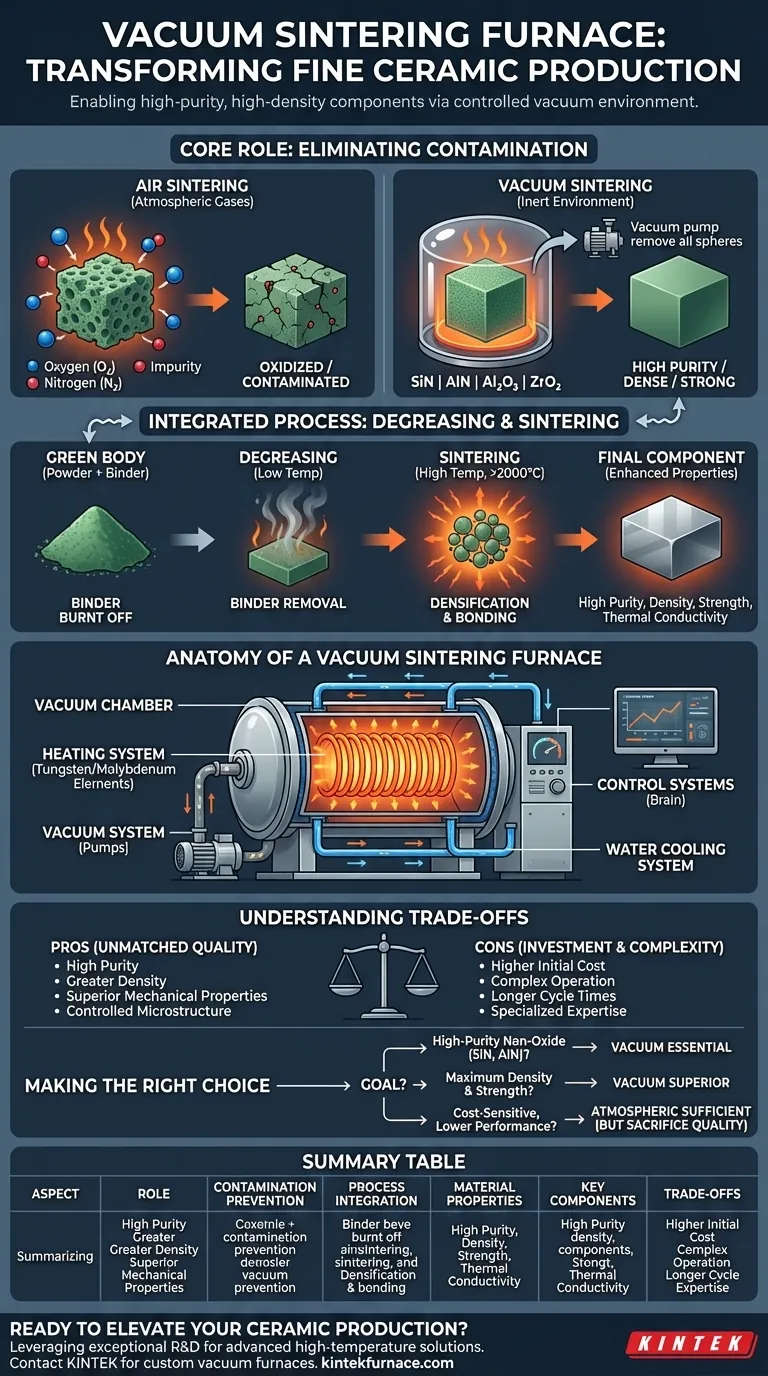

The Core Principle: Eliminating Contamination

Sintering involves heating a compacted powder ("green body") to a high temperature below its melting point, causing the particles to bond and densify.

When performed in air, atmospheric gases like oxygen and nitrogen can react with the ceramic material. This leads to the formation of oxides or nitrides that compromise the material's purity, density, and strength.

A vacuum furnace removes these reactive gases, creating a chemically inert environment. This is absolutely critical for non-oxide ceramics like silicon nitride (SiN) and aluminum nitride (AlN), but also greatly enhances oxide ceramics like aluminum oxide (Al2O3) and zirconium oxide (ZrO2).

The Integrated Process: Degreasing and Sintering

Modern ceramic manufacturing often uses binders to hold the powder in its green body shape. These binders must be removed before sintering, a process called degreasing or debinding.

A vacuum sintering furnace can perform this as a preliminary step in the same cycle. The furnace slowly heats the component to burn off the binder, and the vacuum system safely removes the resulting gases before ramping up to the much higher sintering temperature.

The Result: Enhanced Material Properties

By eliminating atmospheric interference, vacuum sintering allows for unparalleled process control. This precision directly translates to superior final components.

The results are products with higher purity, greater density, reduced porosity, and significantly improved physical and mechanical properties like strength and thermal conductivity.

Anatomy of a Vacuum Sintering Furnace

A vacuum sintering furnace is a complex system where several key components work in concert to create a precisely controlled processing environment.

The Vacuum Chamber

This is the sealed vessel where the entire process takes place. It is engineered to withstand both the extreme internal vacuum and the intense heat radiated from the heating elements.

The Heating System

Heating elements, often made of refractory metals like tungsten or molybdenum, generate the high temperatures required for sintering, which can exceed 2000°C. The heat is transferred to the ceramic workpiece through radiation.

The Vacuum System

A combination of powerful pumps is used to evacuate the chamber, removing air and other gases to create the required vacuum level. This system is responsible for creating and maintaining the inert processing environment.

The Control Systems

Sophisticated temperature and pressure control systems are the brain of the furnace. They manage the precise heating and cooling rates, hold times, and vacuum levels according to a programmed profile, ensuring the process is repeatable and accurate.

The Water Cooling System

An integrated water cooling system circulates through the furnace walls and other critical parts. This prevents the furnace's external shell from overheating and protects vital components like the vacuum pumps and seals.

Understanding the Trade-offs

While vacuum sintering offers unmatched quality, it is a specialized process with important considerations. It represents a significant investment in technology and expertise.

Process Complexity

Operating a vacuum furnace requires a higher level of technical skill than a conventional atmospheric furnace. Managing vacuum levels, programming complex temperature profiles, and ensuring leak-free operation demand well-trained personnel.

Higher Initial Investment

These are sophisticated, high-performance machines. The cost of the furnace itself, along with the necessary infrastructure for vacuum pumps and cooling systems, is substantially higher than for standard kilns.

Longer Cycle Times

Creating a deep vacuum, carefully ramping temperatures to avoid thermal shock, and controlled cooling all contribute to longer overall cycle times compared to simpler atmospheric firing. The trade-off is superior quality and the ability to process sensitive materials.

Making the Right Choice for Your Goal

The decision to use vacuum sintering is driven by the performance requirements of the final component.

- If your primary focus is high-purity non-oxide ceramics (like AlN or SiN): A vacuum furnace is essential to prevent destructive oxidation and achieve the desired material properties.

- If your primary focus is maximum density and mechanical strength: Vacuum sintering provides superior control over densification and grain growth, leading to stronger, more reliable components even for oxide ceramics.

- If your primary focus is cost-sensitive, lower-performance components: Traditional atmospheric sintering may be sufficient, but you will inherently sacrifice the purity, density, and performance benefits of a vacuum process.

Ultimately, adopting vacuum sintering is a commitment to producing components at the highest level of material quality and performance.

Summary Table:

| Aspect | Role in Ceramic Production |

|---|---|

| Contamination Prevention | Eliminates atmospheric gases to avoid oxidation and impurities, ensuring high purity in materials like SiN and AlN. |

| Process Integration | Combines degreasing and sintering in one cycle for efficient binder removal and densification. |

| Material Properties | Enhances density, strength, and thermal conductivity by allowing pure heat-driven particle bonding. |

| Key Components | Includes vacuum chamber, heating system (e.g., tungsten elements), vacuum pumps, and control systems for precision. |

| Trade-offs | Higher cost and complexity, but essential for superior performance in advanced ceramics. |

Ready to elevate your ceramic production with precision and purity? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for laboratories. Our product line, including Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to meet your unique experimental needs—ensuring high-density, contamination-free components. Contact us today to discuss how our vacuum sintering furnaces can transform your material performance and drive innovation in your projects!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes