In short, vacuum melting furnaces are critical for aerospace because they create an environment free of oxygen and other atmospheric contaminants. This prevents reactive metals like titanium and aluminum alloys from forming brittle impurities during the melting process, ensuring the final components possess the immense strength, purity, and reliability demanded by aircraft, satellites, and missiles.

The core issue is risk. In aerospace, material failure is catastrophic. Vacuum melting is not just a manufacturing step; it is a fundamental risk-mitigation process that guarantees the material integrity required for components to survive extreme operational stress.

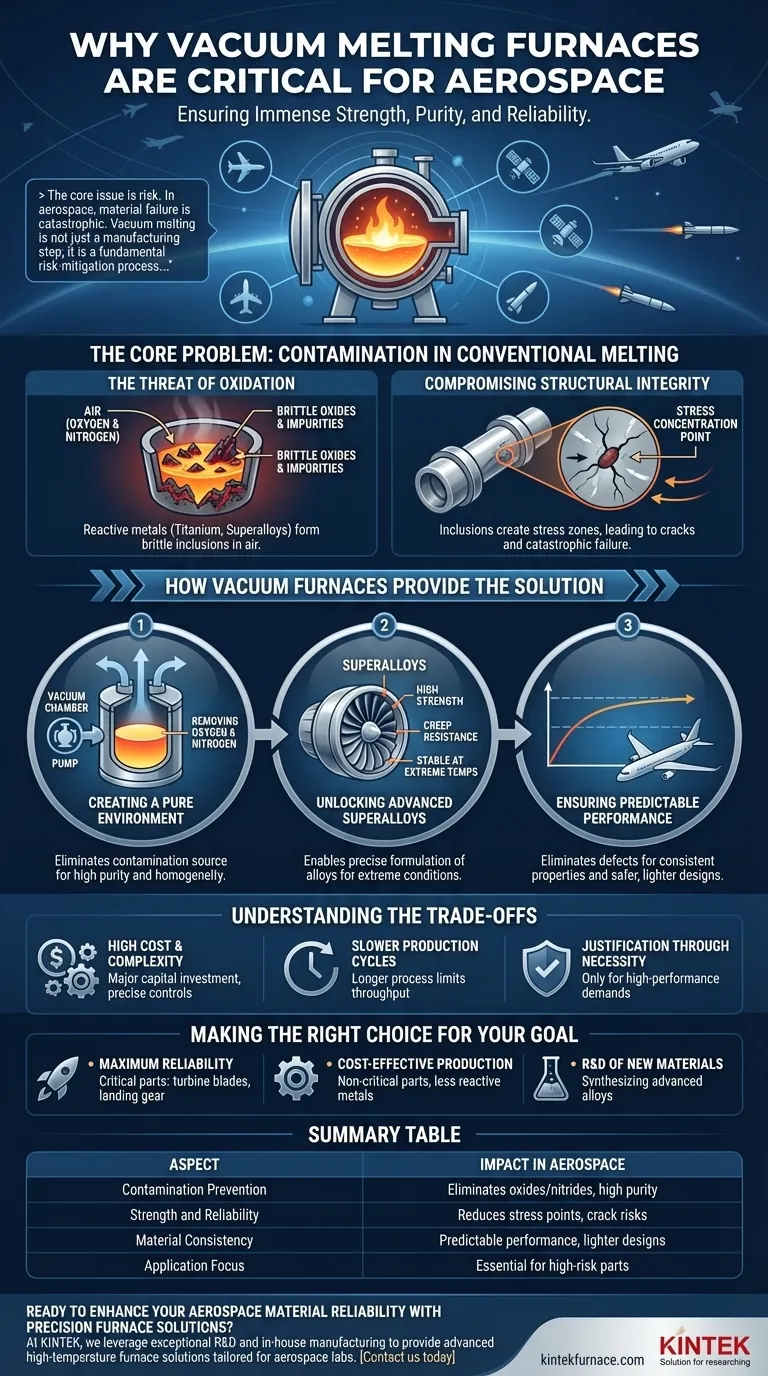

The Core Problem: Contamination in Conventional Melting

When manufacturing parts for aerospace, the very properties that make certain metals desirable also make them difficult to work with. The challenge begins at the most basic level: the air around us.

The Threat of Oxidation

Metals like titanium and nickel-based superalloys are highly reactive, especially when molten. When exposed to oxygen in the air, they rapidly form oxides.

These oxides are brittle, ceramic-like inclusions within the metal's crystalline structure. They are fundamentally different from the pure metal surrounding them.

Compromising Structural Integrity

Even microscopic oxide particles act as stress concentration points. When a component is under load, stress flows around these hard inclusions, creating localized high-stress zones.

Over time, these zones can become the origin points for microscopic cracks. In the high-cycle fatigue environment of aerospace, these cracks can propagate and lead to catastrophic component failure.

How Vacuum Furnaces Provide the Solution

A vacuum furnace directly counters the problem of atmospheric contamination by removing the atmosphere itself. This controlled environment unlocks the full potential of advanced materials.

Creating a Pure Environment

By pumping the air out of the melting chamber, the furnace eliminates the source of contamination—primarily oxygen and nitrogen. This prevents the chemical reactions that form unwanted oxides and nitrides.

The result is a metal melt of exceptionally high purity and chemical homogeneity. This clean foundation is essential for producing materials with predictable and repeatable performance characteristics.

Unlocking Advanced Superalloys

The pristine environment of a vacuum furnace is the only way to create many of the superalloys central to modern jet engines and airframes.

These alloys are precisely formulated with specific elements to achieve incredible strength, creep resistance, and stability at extreme temperatures. The presence of impurities would disrupt this delicate chemical balance and negate the desired properties.

Ensuring Predictable Performance

By eliminating the random defects caused by oxidation, vacuum melting produces components with consistent and verifiable material properties.

Engineers can design parts with tighter safety margins, leading to lighter, more efficient aircraft. The resulting components have a longer lifespan and require fewer repairs, directly enhancing safety and reducing operational costs.

Understanding the Trade-offs

While indispensable for high-performance applications, vacuum furnace technology is not a universal solution. The benefits come with significant costs and complexities.

High Cost and Complexity

Vacuum furnaces are expensive to build, operate, and maintain. The systems required to create and hold a high vacuum, combined with precise heating controls, represent a major capital investment.

Slower Production Cycles

The process of pumping down to a deep vacuum, running the melt cycle, and cooling the material under vacuum is inherently slower than conventional melting processes. This limits throughput and increases the cost per part.

Justification Through Necessity

The high cost is only justified when the application demands performance that is simply unachievable through other means. For non-reactive metals or less critical components, conventional melting remains the more economically viable choice.

Making the Right Choice for Your Goal

The decision to use vacuum melting is driven entirely by the performance requirements and acceptable level of risk for the final component.

- If your primary focus is maximum reliability in extreme environments: For parts like turbine blades, landing gear, or critical airframe structures, vacuum melting is non-negotiable to eliminate material defects.

- If your primary focus is cost-effective production of non-critical parts: For components made from less reactive metals where ultimate performance is not the driver, conventional processes are sufficient.

- If your primary focus is the research and development of new materials: A vacuum furnace is an essential tool for synthesizing and testing advanced alloys with precisely controlled compositions.

Ultimately, leveraging a vacuum furnace is a strategic decision to engineer material certainty into components where failure is not an option.

Summary Table:

| Aspect | Impact in Aerospace |

|---|---|

| Contamination Prevention | Eliminates oxides and nitrides, ensuring high-purity metals like titanium and superalloys. |

| Strength and Reliability | Reduces stress points and crack risks, vital for components under extreme operational stress. |

| Material Consistency | Provides predictable performance, enabling lighter, safer aircraft designs. |

| Application Focus | Essential for turbine blades, landing gear, and other high-risk aerospace parts. |

Ready to enhance your aerospace material reliability with precision furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for aerospace labs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to meet your unique experimental needs. Contact us today to discuss how our vacuum melting furnaces can ensure the purity and performance of your critical components!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications