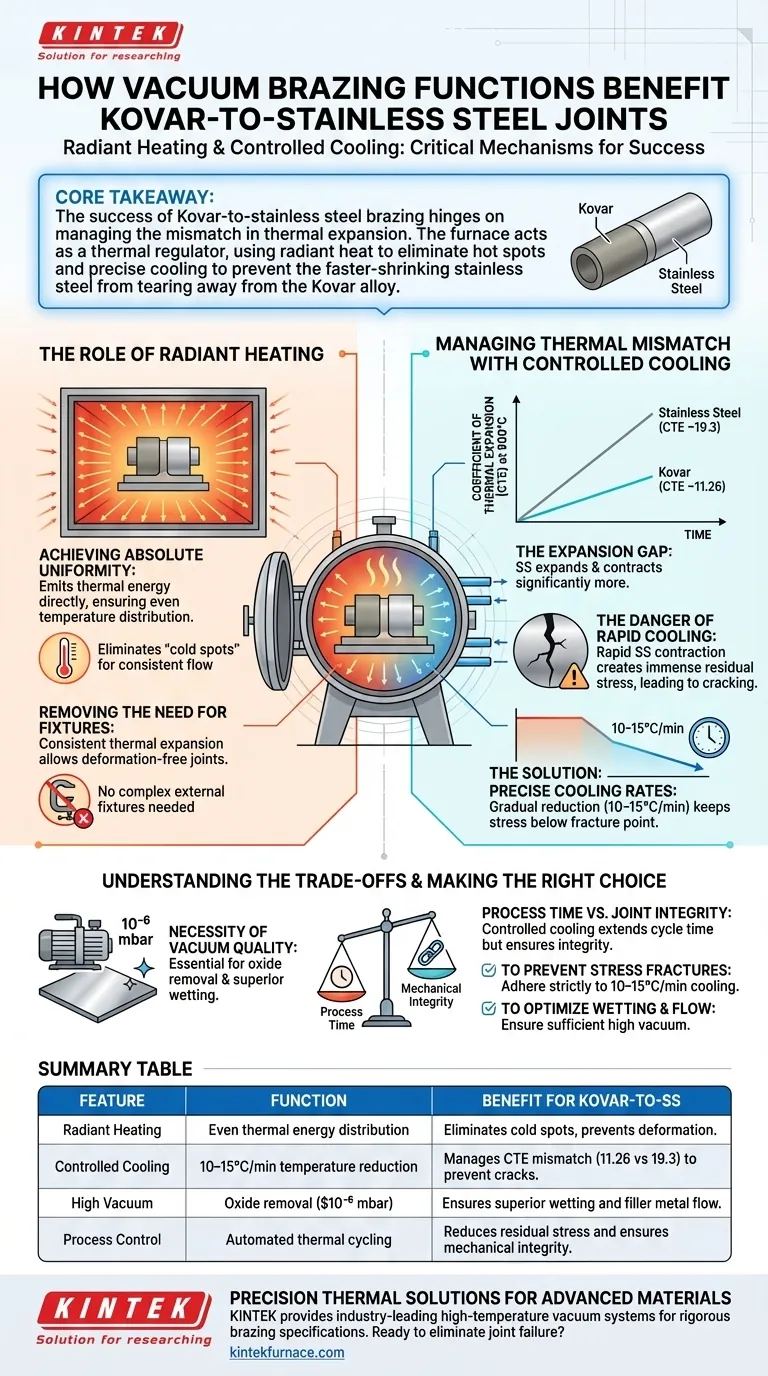

Radiant heating and controlled cooling are the critical mechanisms that allow a vacuum brazing furnace to successfully join materials with vastly different physical properties. While radiant heating guarantees the temperature uniformity required for consistent flow, controlled cooling strictly manages the contraction gap between the two metals to prevent structural failure.

Core Takeaway The success of Kovar-to-stainless steel brazing hinges on managing the mismatch in thermal expansion. The furnace acts as a thermal regulator, using radiant heat to eliminate hot spots and precise cooling to prevent the faster-shrinking stainless steel from tearing away from the Kovar alloy.

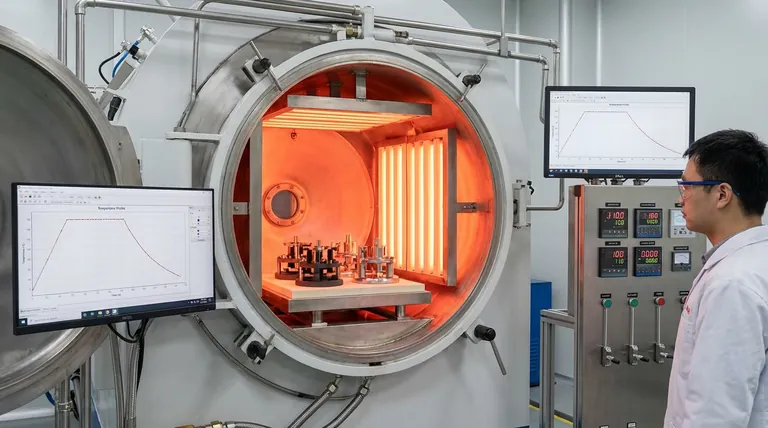

The Role of Radiant Heating

Achieving Absolute Uniformity

Radiant heating functions by emitting thermal energy directly to the workload, ensuring an even temperature distribution across the entire brazing zone.

This eliminates "cold spots" where filler metal might fail to melt or flow properly.

Removing the Need for Fixtures

Because the heat is applied so uniformly, the assembly experiences consistent thermal expansion.

This stability allows for the creation of deformation-free joints without the need for complex external fixtures to hold the parts in place.

Managing Thermal Mismatch with Controlled Cooling

The Expansion Gap

The primary challenge in joining these materials is the difference in their Coefficient of Thermal Expansion (CTE).

At 900°C, Stainless Steel has a CTE of approximately 19.3, while Kovar is much lower at 11.26.

This means Stainless Steel expands and contracts significantly more than Kovar during the thermal cycle.

The Danger of Rapid Cooling

If the assembly is cooled too quickly, the Stainless Steel will contract rapidly, pulling against the more stable Kovar.

This creates immense residual thermal stress at the interface, which often leads to immediate cracking or eventual joint failure.

The Solution: Precise Cooling Rates

The vacuum furnace mitigates this risk through a controlled cooling rate, typically set between 10 to 15 degrees Celsius per minute.

This gradual reduction in temperature allows the materials to contract in equilibrium, keeping stress levels below the fracture point.

Understanding the Trade-offs

The Necessity of Vacuum Quality

While thermal management is the key to preventing cracks, it is ineffective without a pristine vacuum environment.

Radiant heating requires a high vacuum (e.g., $10^{-6}$ mbar) to allow oxide removal; if the vacuum is poor, oxides will remain, and the filler metal will not wet the surface regardless of the temperature profile.

Process Time vs. Joint Integrity

The controlled cooling phase significantly extends the cycle time compared to standard brazing.

You are effectively trading production speed for mechanical integrity. Rushing the cooling phase to increase throughput will almost invariably result in cracked joints when working with CTE mismatches of this magnitude.

Making the Right Choice for Your Goal

To achieve the best results in Kovar-to-stainless steel brazing, align your process parameters with your specific requirements:

- If your primary focus is preventing stress fractures: Adhere strictly to a cooling rate of 10–15°C/min to accommodate the CTE mismatch (11.26 vs 19.3).

- If your primary focus is wetting and flow: Ensure your vacuum levels are sufficient to remove oxide films, allowing the radiant heat to promote ideal spreading.

Success in this application relies not just on reaching the right temperature, but on precisely controlling how you return from it.

Summary Table:

| Feature | Function | Benefit for Kovar-to-SS |

|---|---|---|

| Radiant Heating | Even thermal energy distribution | Eliminates cold spots and prevents part deformation |

| Controlled Cooling | 10–15°C/min temperature reduction | Manages CTE mismatch (11.26 vs 19.3) to prevent cracks |

| High Vacuum | Oxide removal ($10^{-6}$ mbar) | Ensures superior wetting and filler metal flow |

| Process Control | Automated thermal cycling | Reduces residual stress and ensures mechanical integrity |

Precision Thermal Solutions for Your Advanced Materials

Success in joining materials with mismatched thermal expansion requires more than just heat; it requires absolute control. KINTEK provides industry-leading high-temperature vacuum systems designed to handle the most rigorous brazing specifications.

Whether you are joining Kovar to stainless steel or developing new material interfaces, our laboratory and industrial furnaces offer the stability you need. Backed by expert R&D and world-class manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable for your unique research or production needs.

Ready to eliminate joint failure and optimize your thermal process? Contact our engineering team today to find the perfect furnace solution for your application.

Visual Guide

References

- The Influence of the Size of the Brazing Gap on the Structure and Strength of Kovar Joints with Stainless Steel. DOI: 10.15407/mfint.47.03.0271

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What materials are used in the chamber design of laboratory vacuum furnaces? Optimize for High-Temp and Purity

- Why is a vacuum drying oven essential for High-Entropy Marimo (HE-MARIMO)? Protect Structural Integrity

- Why is a high-vacuum environment required before vacuum hot rolling? Ensure Superior Clad Plate Bonding Integrity

- What is the difference between a muffle furnace and a vacuum furnace? Choose the Right Heat for Your Process

- What types of materials and processes are compatible with vacuum furnaces? Achieve Purity and Precision in Heat Treatment

- What are the core tasks of vacuum and temperature systems in CSS for CZT films? Essential Control for High Performance

- How does a high-temperature vacuum furnace contribute to the temperature calibration of Co3O2BO3? Unlock Data Precision

- Why is it necessary to treat porous carbon samples in a vacuum drying oven at 90 °C before electrode coating?