Vacuum drying is the critical safeguard for the structural and chemical integrity of High-Entropy Marimo (HE-MARIMO) particles. By significantly reducing atmospheric pressure, these ovens allow volatile solvents to evaporate rapidly at temperatures as low as 40 °C. This low-temperature environment is essential to prevent the unwanted oxidation of organic additives and to stop the delicate, spherical precursors from collapsing or clumping together during the drying stage.

The essential role of a vacuum drying oven lies in its ability to decouple solvent evaporation from high thermal energy. By lowering the boiling point of residual liquids, it preserves the intricate "Marimo-like" morphology and porous architecture that are vital for the material's eventual performance.

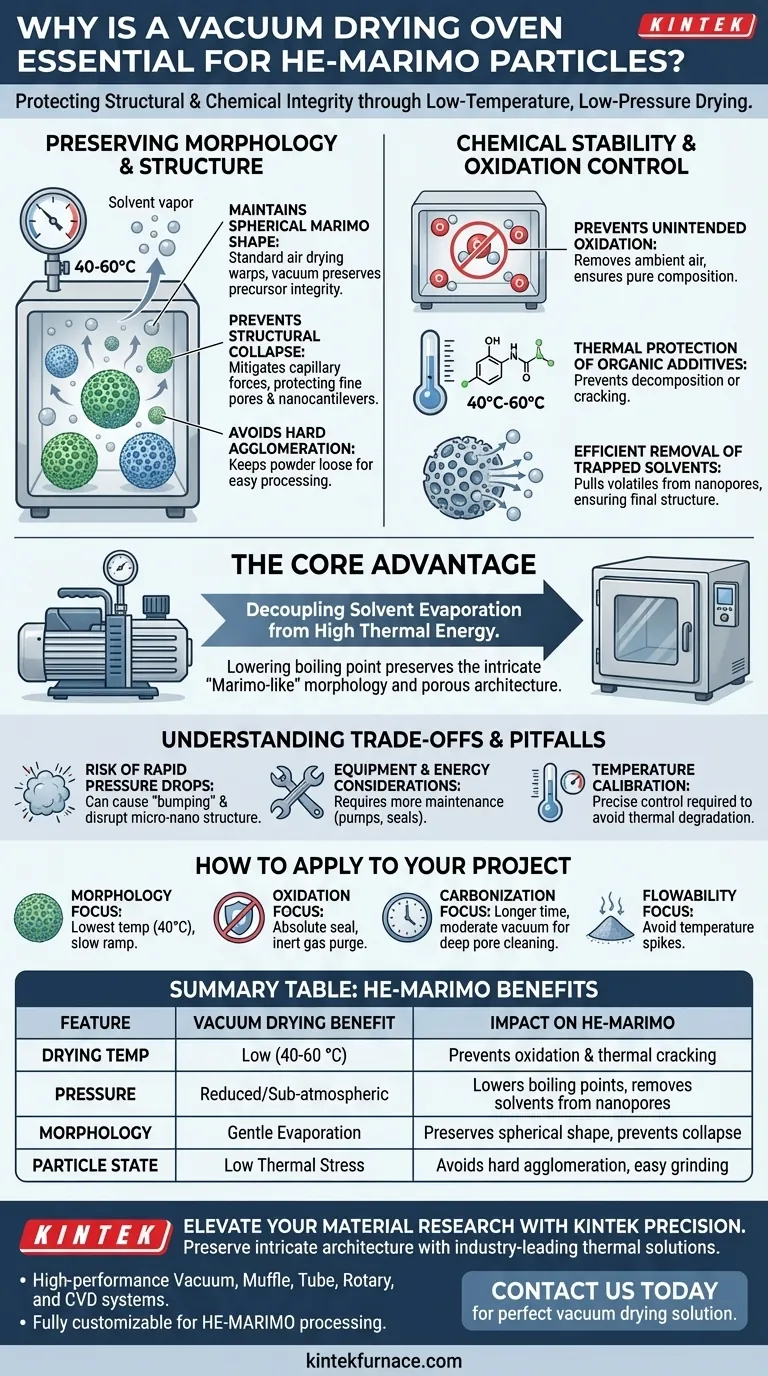

Preserving Morphological and Structural Integrity

Maintaining the Spherical Marimo Shape

The HE-MARIMO particles rely on a specific spherical morphology that provides a high surface-to-volume ratio. Standard air drying often introduces high thermal stress that can warp these shapes, whereas vacuum drying ensures the precursor integrity remains intact.

Preventing Structural Collapse and Capillary Force Damage

In materials with fine pores or nanocantilevers, the surface tension of evaporating liquids can cause structural collapse. A vacuum environment mitigates these capillary forces by allowing solvents to volatilize more gently at lower temperatures, protecting the spatial distribution of the material’s components.

Avoiding Hard Agglomeration

High-temperature drying in a standard oven often leads to hard agglomeration, where particles fuse into a solid mass. Vacuum drying maintains the loose physical properties of the powder, ensuring it remains easy to grind and process in subsequent manufacturing steps.

Chemical Stability and Oxidation Control

Preventing Unintended Oxidation

High-entropy precursors often contain active sites or organic additives that are sensitive to oxygen at elevated temperatures. A vacuum oven removes the ambient air, preventing oxidative deterioration and ensuring the chemical composition of the HE-MARIMO remains pure.

Thermal Protection of Organic Additives

Organic components within the precursor can decompose or undergo unwanted cracking if exposed to high heat. By achieving thorough drying at 40 °C to 60 °C, the vacuum process keeps these organic frameworks stable for later stages of carbonization or calcination.

Efficient Removal of Trapped Solvents

Residual solvents like methanol or tetrahydrofuran can become trapped deep within nanopores. The reduced pressure of a vacuum oven pulls these volatiles out from the internal structure, preventing them from interfering with the material's final chemical structure.

Understanding the Trade-offs and Potential Pitfalls

The Risk of Rapid Pressure Drops

While a vacuum is necessary, applying it too quickly can cause "bumping," where the solvent boils explosively. This can physically disrupt the fine micro-nano structure of the HE-MARIMO particles, potentially ruining the batch's uniformity.

Equipment and Energy Considerations

Vacuum drying ovens require more maintenance than standard convection ovens due to the need for vacuum pumps and seals. Additionally, the process can sometimes be slower for bulk materials because heat transfer is less efficient in a vacuum than in moving air.

Temperature Calibration Requirements

Precise control is required to ensure the temperature is high enough to move the solvent but low enough to avoid thermal degradation. Users must calibrate the oven specifically for the solvent being removed (e.g., water vs. organic solvents) to avoid structural instability.

How to Apply This to Your Project

To achieve the best results with HE-MARIMO or similar high-entropy precursors, align your drying strategy with your specific material goals:

- If your primary focus is morphology preservation: Use the lowest possible temperature (40 °C) and a slow, staged vacuum ramp to prevent the collapse of spherical structures.

- If your primary focus is preventing oxidation: Ensure the vacuum seal is absolute and consider purging the chamber with an inert gas like nitrogen before starting the vacuum cycle.

- If your primary focus is subsequent carbonization: Prioritize a longer drying time at a moderate vacuum to ensure 100% of residual solvents are removed from deep pores.

- If your primary focus is particle flowability: Aim for a "loose" dried powder by avoiding any temperature spikes that could trigger surface sintering or agglomeration.

By mastering the vacuum drying process, you ensure that the sophisticated design of your high-entropy materials survives the transition from liquid synthesis to solid-state application.

Summary Table:

| Feature | Vacuum Drying Benefit | Impact on HE-MARIMO |

|---|---|---|

| Drying Temp | Low (40-60 °C) | Prevents oxidation and thermal cracking of organics |

| Pressure | Reduced/Sub-atmospheric | Lowers boiling points to remove solvents from nanopores |

| Morphology | Gentle Evaporation | Preserves spherical shape and prevents structural collapse |

| Particle State | Low Thermal Stress | Avoids hard agglomeration for easy grinding/processing |

Elevate Your Material Research with KINTEK Precision

Preserve the intricate architecture of your high-entropy precursors with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum, Muffle, Tube, Rotary, and CVD systems—all fully customizable to meet the rigorous demands of HE-MARIMO processing and beyond.

Don't let structural collapse or unintended oxidation compromise your results. Contact us today to find the perfect vacuum drying solution and see how our advanced lab furnaces can enhance your material integrity and laboratory efficiency.

Visual Guide

References

- Ayano Taniguchi, Kazuya Kobiro. Low-temperature synthesis of porous high-entropy (CoCrFeMnNi)<sub>3</sub>O<sub>4</sub> spheres and their application to the reverse water–gas shift reaction as catalysts. DOI: 10.1039/d3dt04131j

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is the significance of precise temperature control in a vacuum furnace? Ensure Quality, Consistency, and Reliability

- How is furnace brazing used in research and development? Unlock Precision Joining for Material Innovation

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- How do modern vacuum furnaces improve energy efficiency? Achieve Superior Thermal Processing with Lower Energy Costs

- Why is a vacuum oven required for post-processing WTaVTiZrx alloy powders? Ensure Purity and Prevent Oxidation

- Why is a vacuum annealing furnace required for WSe2 Schottky detectors? Optimize Interfaces for Peak Performance

- How do continuous vacuum furnaces improve energy efficiency in metal heat treatment? Achieve Superior Heat Treatment Efficiency

- What methods are used for cooling parts after vacuum furnace heat treatment? Optimize Your Metal Properties