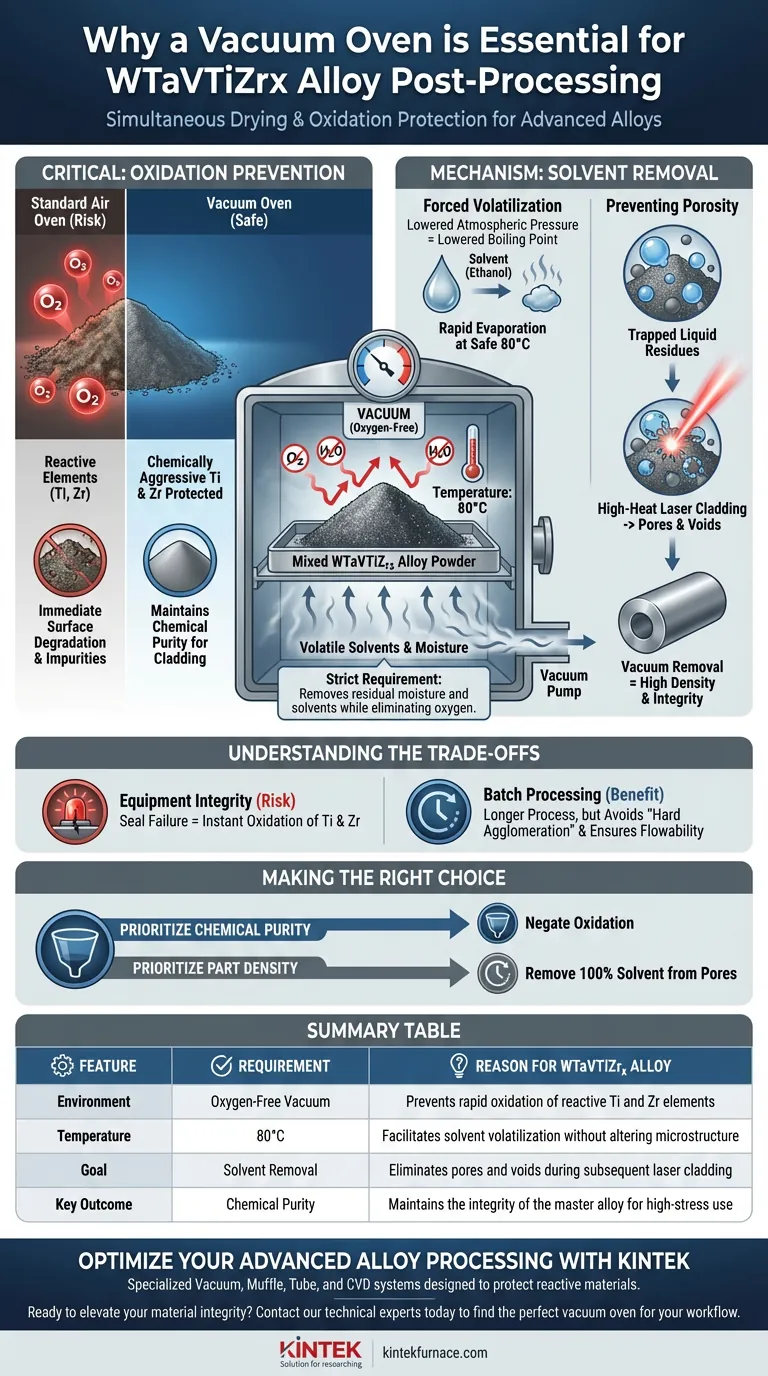

A vacuum oven is strictly required for the post-processing of mixed WTaVTiZrx alloy powders to simultaneously dry the material and protect its chemical composition. This process utilizes a temperature of 80°C to thoroughly remove residual moisture and solvents while eliminating the presence of oxygen. This oxygen-free environment is the only safe way to heat the powder, as it prevents the highly active Titanium (Ti) and Zirconium (Zr) components from oxidizing during the drying phase.

The vacuum environment facilitates the rapid volatilization of solvents at safe temperatures, ensuring the alloy remains free of oxides and moisture that would otherwise compromise subsequent laser cladding applications.

The Critical Role of Oxidation Prevention

Protecting Highly Reactive Elements

The WTaVTiZrx alloy contains Titanium (Ti) and Zirconium (Zr), both of which are chemically aggressive metals.

These elements are prone to rapid oxidation when exposed to heat in the presence of air. Even at the relatively low drying temperature of 80°C, processing these powders in a standard air oven would lead to immediate surface degradation.

Ensuring Chemical Purity for Cladding

The primary goal of the post-processing stage is to prepare the "master alloy" for melting or laser cladding.

If the powder oxidizes during drying, those impurities become permanent inclusions in the final metal matrix. By utilizing a vacuum, you maintain the extreme chemical purity necessary for the alloy to perform as intended in high-stress applications.

Mechanisms of Solvent Removal

Forced Volatilization at Low Temperatures

Vacuum drying works by lowering the atmospheric pressure surrounding the powder.

This pressure reduction significantly lowers the boiling point of residual solvents (such as ethanol) and water. It forces these liquids to evaporate (volatilize) rapidly without requiring extreme temperatures that could alter the powder's microstructure.

Preventing Porosity and Defects

Liquid residues trapped within powder pores can wreak havoc during subsequent sintering or melting steps.

If solvents remain in the powder, they will rapidly expand into gas during the high-heat laser cladding process, creating pores or voids in the final sample. The vacuum oven ensures deep, complete removal of these volatile organics, securing the high density and integrity of the final part.

Understanding the Trade-offs

Equipment Integrity is Paramount

The effectiveness of this process relies entirely on the quality of the vacuum seal.

If the vacuum pump fails or the seal breaks while the oven is at 80°C, the sudden influx of air will oxidize the heated Ti and Zr faster than if they were at room temperature. Continuous monitoring of pressure levels is required to prevent batch ruin.

Batch Processing Time

Vacuum drying is a diffusion-controlled process that may take longer than high-heat convection drying.

While it is slower, it avoids the "hard agglomeration" of particles often caused by rapid, high-temperature drying. Attempting to rush this process with higher heat risks compromising the powder's flowability and packing density.

Making the Right Choice for Your Goal

To maximize the quality of your WTaVTiZrx alloy, align your drying parameters with your specific processing needs:

- If your primary focus is Chemical Purity: Prioritize maintaining a deep vacuum to absolutely negate oxidation of the Titanium and Zirconium fractions.

- If your primary focus is Part Density: Ensure the drying cycle is sufficiently long to remove 100% of the solvent from the powder pores, preventing gas-induced voids during cladding.

By isolating your reactive powders from oxygen while driving out solvents, you secure the foundational integrity required for advanced alloy manufacturing.

Summary Table:

| Feature | Requirement | Reason for WTaVTiZrx Alloy |

|---|---|---|

| Environment | Oxygen-Free Vacuum | Prevents rapid oxidation of reactive Ti and Zr elements |

| Temperature | 80°C | Facilitates solvent volatilization without altering microstructure |

| Goal | Solvent Removal | Eliminates pores and voids during subsequent laser cladding |

| Key Outcome | Chemical Purity | Maintains the integrity of the master alloy for high-stress use |

Optimize Your Advanced Alloy Processing with KINTEK

Don't let oxidation or porosity compromise your research. Backed by expert R&D and precision manufacturing, KINTEK offers specialized Vacuum, Muffle, Tube, and CVD systems designed to protect reactive materials like WTaVTiZrx. Whether you need a standard solution or a system fully customizable for your unique laboratory needs, our high-temp furnaces ensure the chemical purity your applications demand.

Ready to elevate your material integrity? Contact our technical experts today to find the perfect vacuum oven for your workflow.

Visual Guide

References

- Xiaoyu Ding, Jianhua Yao. Study on Microstructure and High Temperature Stability of WTaVTiZrx Refractory High Entropy Alloy Prepared by Laser Cladding. DOI: 10.3390/e26010073

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Why use vacuum and argon in pulse solidification? Protect your Aluminum-Silicon alloys from oxidation and contamination

- How do continuous vacuum furnaces improve energy efficiency in metal heat treatment? Achieve Superior Heat Treatment Efficiency

- Why are vacuum ovens and argon gas protection necessary for MXene monoliths? Ensure Density and Chemical Integrity

- What is the hot zone in a vacuum furnace? Key Components and Performance Insights

- Why is a high-vacuum brazing furnace required for Kovar and stainless steel? Achieve Superior Oxide-Free Joints

- What is the purpose of a vacuum furnace? Achieve Superior Material Quality and Purity

- What operational flexibility do multiple-chamber vacuum furnaces provide? Boost Efficiency with Continuous Processing

- What is the significance of a high-temperature vacuum sintering furnace? Achieving Ho:Y2O3 Optical Transparency