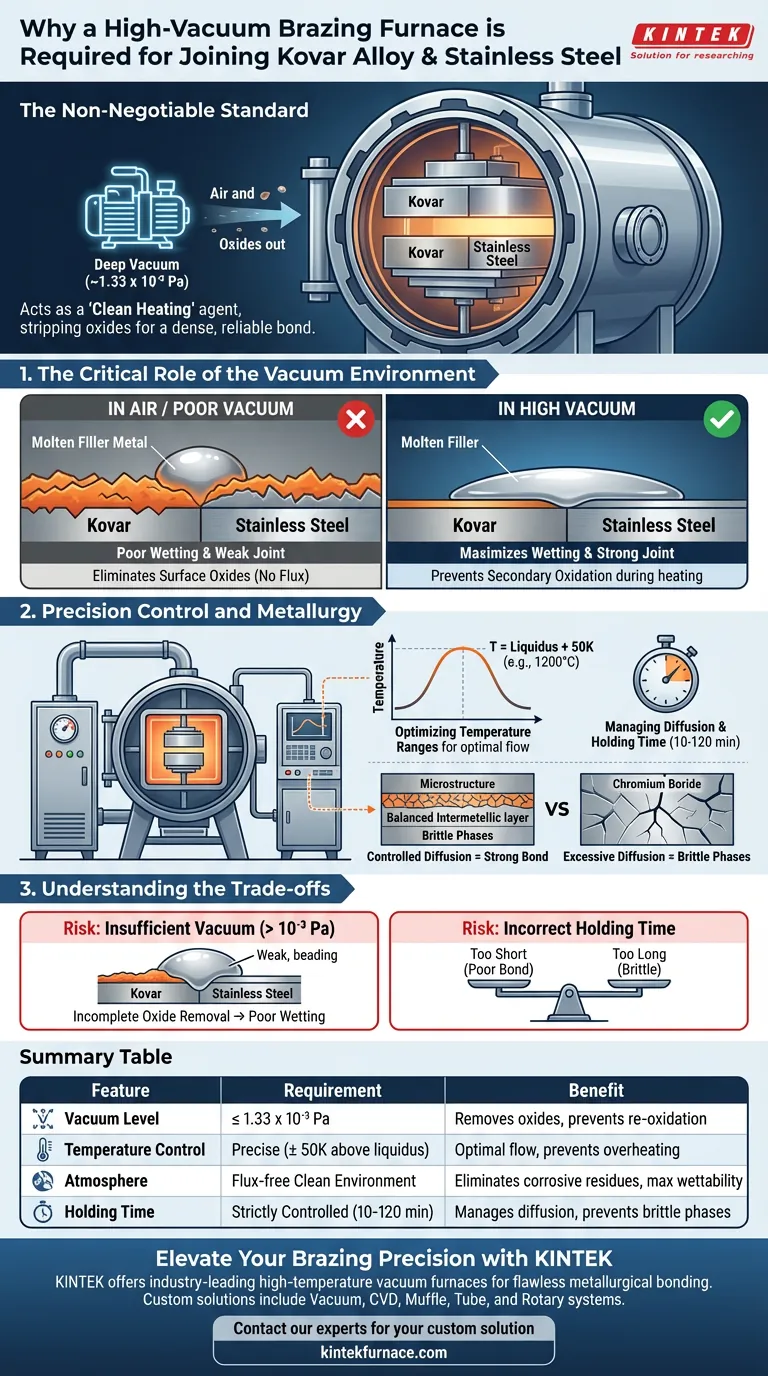

A high-vacuum brazing furnace is the non-negotiable standard for joining Kovar alloy and stainless steel because it creates the specific environmental conditions required to strip away surface oxides. By maintaining a deep vacuum—typically around $1.33 \times 10^{-3} \text{ Pa}$—the furnace prevents the base metals and filler from re-oxidizing during the heating process, ensuring the liquid filler can properly wet the surface and create a structural bond.

The core function of the high-vacuum environment is to act as a "clean heating" agent, effectively removing existing oxide films and shielding the materials from secondary oxidation to ensure a dense, reliable metallurgical connection.

The Critical Role of the Vacuum Environment

Eliminating Surface Oxides

Both Kovar and stainless steel naturally develop oxide films on their surfaces. These films act as a physical barrier that prevents brazing filler metals from bonding with the substrate.

A high-vacuum furnace effectively removes these oxide films without the need for corrosive chemical fluxes. This ensures the base metal is chemically active and ready to bond.

Preventing Secondary Oxidation

Metals become highly reactive as temperatures rise. If heated in air or a poor vacuum, the base metals and the filler metal would oxidize rapidly, ruining the joint.

The vacuum environment prevents this "secondary oxidation." It maintains a pristine atmosphere throughout the entire heating cycle, protecting the integrity of the materials.

Maximizing Wettability and Spreading

For a strong joint, the molten filler metal must flow smoothly across the base metal, a property known as wettability.

Oxides are the primary enemy of wettability. By ensuring an oxide-free surface, the high-vacuum environment allows the filler metal to spread evenly and penetrate the joint gap completely.

Precision Control and Metallurgy

Optimizing Temperature Ranges

Beyond cleanliness, these furnaces offer precise thermal regulation. High-quality joints generally require processing at specific temperatures, often around 50 K above the liquidus temperature of the filler metal (e.g., $1200^\circ\text{C}$).

This precision ensures the filler flows optimally without overheating the sensitive base materials.

Managing Diffusion and Brittle Phases

The strength of a Kovar-to-stainless steel joint is dictated by how elements diffuse between the metals. However, excessive diffusion can lead to the formation of brittle intermediate phases, such as chromium borides.

High-vacuum furnaces allow for exact control over "holding time" (e.g., 10, 30, or 120 minutes). This enables engineers to fine-tune the process, ensuring enough diffusion for a strong bond while limiting the growth of brittle structures that could cause cracking.

Understanding the Trade-offs

The Risk of Insufficient Vacuum

If the vacuum level is not sufficiently low (e.g., weaker than $10^{-6} \text{ mbar}$ or $1.33 \times 10^{-3} \text{ Pa}$), oxide removal will be incomplete.

This leads to poor wetting, where the filler metal beads up rather than spreading, resulting in a weak or discontinuous joint.

Balancing Time and Brittleness

There is a delicate balance regarding the holding time at peak temperature. Short times may not allow for sufficient filler flow or bonding.

However, extending the holding time too long promotes the growth of brittle intermetallic compounds. This reduces the mechanical integrity of the joint, making it susceptible to failure under stress.

Making the Right Choice for Your Goal

To ensure the success of your brazing project, align your process parameters with your specific mechanical requirements:

- If your primary focus is wetting and coverage: Prioritize achieving and maintaining the deepest possible vacuum level to guarantee complete oxide removal.

- If your primary focus is mechanical toughness: Strictly control the holding time to limit the formation of brittle chromium boride phases at the joint interface.

- If your primary focus is process repeatability: Utilize the precise temperature controls to maintain the process at exactly 50 K above the filler's liquidus temperature.

Success in vacuum brazing relies on treating the vacuum not just as an empty space, but as an active tool for surface preparation and chemical control.

Summary Table:

| Feature | High-Vacuum Brazing Requirement | Benefit for Kovar/Stainless Steel |

|---|---|---|

| Vacuum Level | $\leq 1.33 \times 10^{-3}$ Pa | Removes surface oxides and prevents secondary oxidation |

| Temperature Control | Precise ($\pm$ 50 K above liquidus) | Ensures optimal filler flow without overheating base metals |

| Atmosphere | Flux-free Clean Environment | Eliminates corrosive residues and maximizes wettability |

| Holding Time | Strictly Controlled (10-120 min) | Manages element diffusion to prevent brittle phase formation |

Elevate Your Brazing Precision with KINTEK

Don't let oxidation compromise the integrity of your critical Kovar and stainless steel joints. KINTEK provides industry-leading high-temperature vacuum furnaces designed to deliver the deep vacuum levels and thermal precision required for flawless metallurgical bonding.

Backed by expert R&D and manufacturing, KINTEK offers Vacuum, CVD, Muffle, Tube, and Rotary systems, all fully customizable to meet your unique laboratory or production specifications. Ensure maximum joint toughness and repeatable results with our specialized heating solutions.

Ready to optimize your brazing process? Contact our experts today to find your custom solution.

Visual Guide

References

- The Influence of the Size of the Brazing Gap on the Structure and Strength of Kovar Joints with Stainless Steel. DOI: 10.15407/mfint.47.03.0271

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How does high-temperature vacuum processing improve phosphor ceramics? Boost Thermal Stability in High-Power Lasers

- What is the purpose of the internal circulation pure water cooling system in vacuum sintering furnaces? Ensure Reliable Heat Management for High-Temperature Sintering

- How does a vacuum drying oven provide superior results for Cs3Cu2I5:Tb precipitates? Preserve Your Scintillation Quality

- What is the purpose of a vacuum sintering furnace? Create High-Performance Parts with Superior Purity

- Why is repeated flipping and remelting required in vacuum arc furnaces? Achieving Uniform Refractory Alloy Ingots

- How do high-vacuum or inert gas furnaces contribute to the precision heat treatment of nickel-based superalloys?

- Why must the drying process for MXene-coated electrodes be conducted in a vacuum drying oven? Key Stability Factors

- What maintenance is required for vacuum furnace heating elements? Ensure Reliability and Prevent Costly Downtime