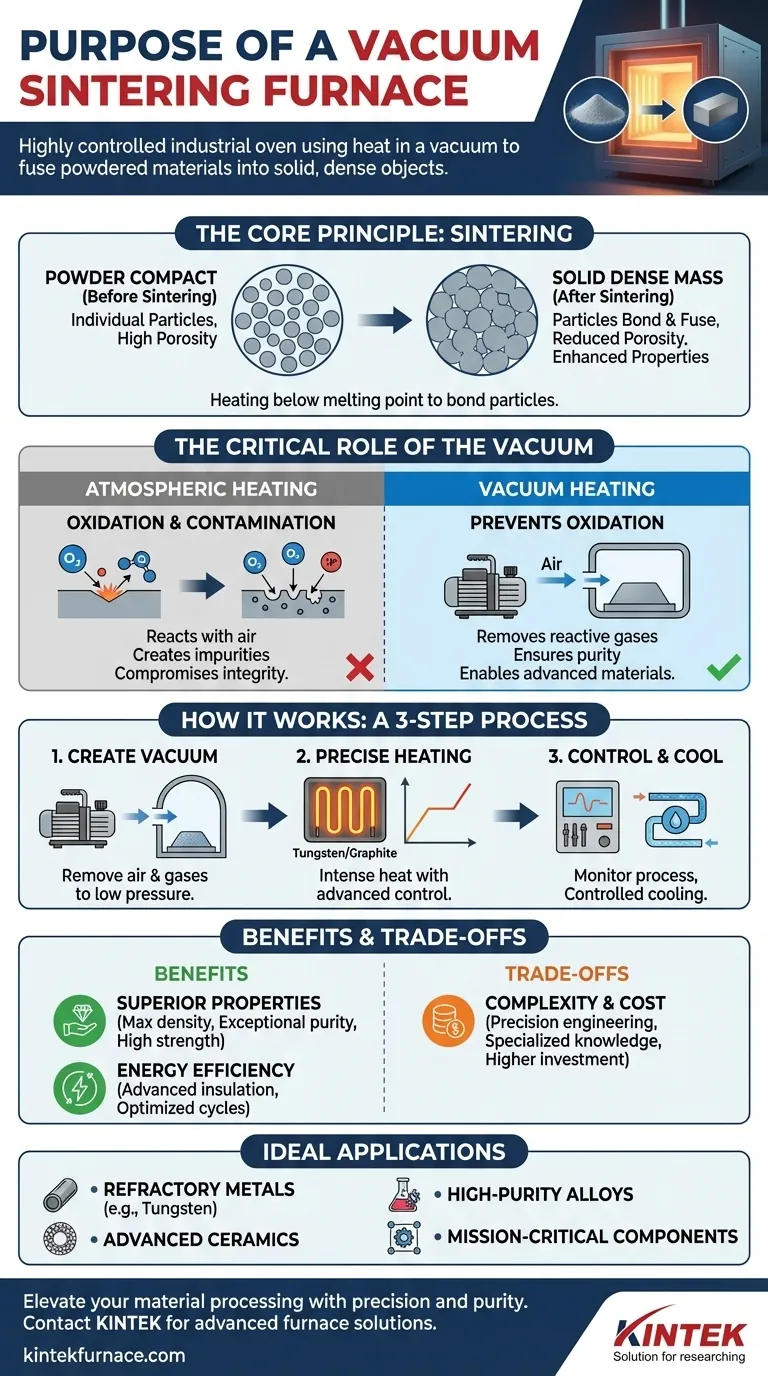

In essence, a vacuum sintering furnace is a highly controlled industrial oven that uses heat in a vacuum to fuse powdered materials into a solid, dense object. Its primary purpose is to create high-performance parts by preventing the chemical reactions, like oxidation, that would otherwise occur when heating materials in the presence of air.

The true value of a vacuum sintering furnace is not just its ability to generate high temperatures, but its power to create an ultra-pure environment. This controlled atmosphere is what allows for the fabrication of advanced materials with superior strength, purity, and performance that are impossible to achieve through conventional heating methods.

The Core Principle: Sintering Explained

What is Sintering?

Sintering is a thermal process that transforms a powder compact into a dense, solid mass. It involves heating the material to a high temperature, but crucially, below its melting point.

At this elevated temperature, the individual particles of the powder begin to bond and fuse together at their contact points. Over time, this process reduces the empty space (porosity) between particles, causing the object to shrink and densify.

Why Sintering is Used

The goal of sintering is to fundamentally enhance a material's properties. By creating a dense, solid structure from a powder, the process dramatically improves characteristics like mechanical strength, hardness, thermal conductivity, and electrical conductivity.

The Critical Role of the Vacuum

Preventing Oxidation and Contamination

When most materials are heated to high temperatures, they readily react with oxygen and other gases in the air. This reaction, known as oxidation, can create impurities and surface defects, compromising the final part's integrity.

A vacuum furnace works by first pumping nearly all the air out of its sealed chamber. By removing the reactive gases, it creates a clean environment that prevents these unwanted chemical reactions from ever starting.

Ensuring Material Purity and Performance

The vacuum environment is essential for producing parts with exceptional purity and predictable performance. By eliminating the risk of contamination from atmospheric gases, the material can achieve its ideal theoretical density and properties.

This level of control is non-negotiable for high-stakes applications where even minuscule impurities can lead to component failure.

Enabling Advanced Materials

Many advanced materials, such as refractory metals (like tungsten), advanced ceramics, and certain metal alloys, are highly reactive at sintering temperatures. A vacuum environment is the only way to process them without compromising their unique and valuable properties.

How a Vacuum Sintering Furnace Works

Step 1: Creating the Vacuum

The process begins with the vacuum system. A series of pumps removes air and other gases from the sealed furnace chamber until a specific, low-pressure level is reached.

Step 2: Precise Heating

Once the vacuum is established, the heating system activates. Electric heating elements, often made of tungsten or graphite, generate intense heat. An advanced temperature control system precisely manages the heating rate and final temperature to follow a specific profile designed for the material.

Step 3: Integrated Control and Cooling

Throughout the process, a control system monitors and regulates the vacuum level and temperature. After the heating cycle is complete, a water cooling system integrated into the furnace walls helps to cool the chamber and the finished part in a controlled manner.

Understanding the Trade-offs and Benefits

Benefit: Superior Material Properties

The primary advantage is the ability to produce parts with maximum density, exceptional purity, and superior mechanical strength. The process avoids the defects and weaknesses caused by oxidation.

Benefit: Energy Efficiency

Modern vacuum furnaces are designed with advanced insulation materials and sophisticated control systems. This minimizes heat loss and optimizes the heating cycle, leading to lower energy consumption compared to older or less-controlled technologies.

Trade-off: Complexity and Cost

Vacuum sintering furnaces are complex, precision-engineered machines. They represent a significant capital investment and require specialized knowledge for operation and maintenance, making them more costly than simpler atmospheric furnaces.

Is a Vacuum Sintering Furnace Right for Your Application?

Choosing the right thermal processing technology depends entirely on your material and performance goals.

- If your primary focus is producing high-performance, oxidation-sensitive materials (like refractory metals or advanced ceramics): A vacuum furnace is not just an option; it is often the only viable path to success.

- If your primary focus is maximum part density and purity for mission-critical components: The controlled environment of a vacuum furnace provides unmatched repeatability and quality assurance.

- If your primary focus is densifying standard materials with low sensitivity to oxidation: A simpler and more cost-effective atmospheric furnace may be sufficient for your needs.

Ultimately, adopting vacuum sintering is a decision to prioritize material quality and performance above all else.

Summary Table:

| Aspect | Key Details |

|---|---|

| Primary Purpose | Fuse powdered materials into solid, dense objects in a vacuum to prevent oxidation and ensure high purity. |

| Core Benefits | Superior material strength, purity, and performance; energy efficiency; ideal for oxidation-sensitive materials. |

| Ideal Applications | Refractory metals, advanced ceramics, metal alloys requiring high density and purity for critical components. |

| Process Steps | 1. Create vacuum; 2. Precise heating; 3. Controlled cooling and monitoring. |

| Trade-offs | Higher complexity and cost compared to atmospheric furnaces, but essential for quality and performance. |

Ready to elevate your material processing with precision and purity? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're working with refractory metals, ceramics, or other advanced materials, our vacuum sintering furnaces ensure maximum density, purity, and performance for mission-critical applications. Contact us today to discuss how we can help you achieve superior results and optimize your laboratory efficiency!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the purpose of performing medium vacuum annealing on working ampoules? Ensure Pure High-Temp Diffusion

- What is the role of sintering or vacuum induction furnaces in battery regeneration? Optimize Cathode Recovery

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density