High-temperature vacuum processing fundamentally transforms thermal management by establishing a seamless physical interface between the phosphor ceramic layer and a high-thermal-conductivity sapphire substrate. By eliminating interfacial thermal resistance, this method allows the substrate to act as a highly efficient heat sink, drastically lowering the operating temperature of the composite during intense laser excitation.

The core value of this process is the elimination of thermal bottlenecks. By unifying the ceramic and sapphire layers, the composite avoids thermal quenching and brightness saturation, maintaining peak performance at optical power densities that would overheat traditional pure ceramics.

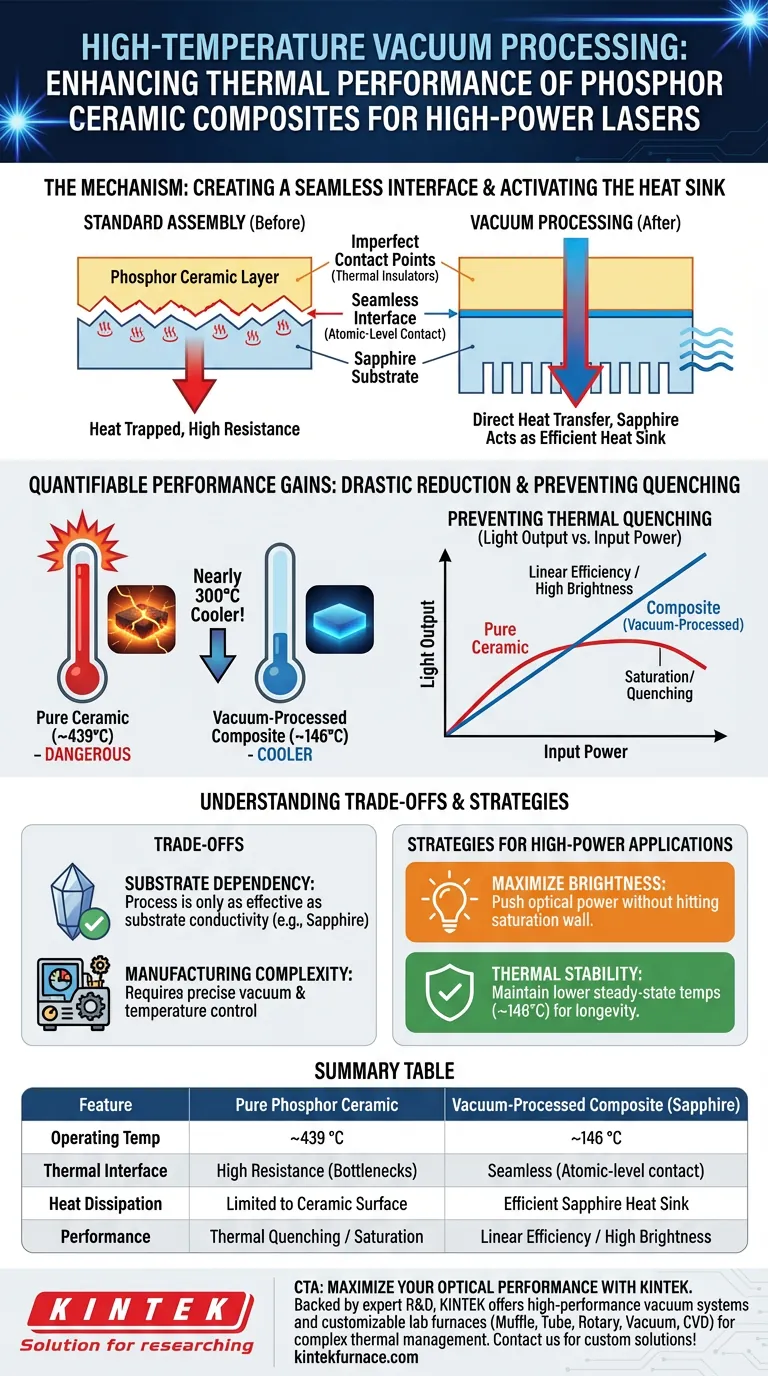

The Mechanism of Thermal Improvement

Creating a Seamless Interface

The primary function of high-temperature vacuum processing is to fuse the phosphor ceramic to the substrate without microscopic gaps or voids.

In standard assembly, imperfect contact points act as thermal insulators, trapping heat within the active layer. Vacuum processing removes these barriers, ensuring direct, atomic-level contact across the entire surface area.

Activating the Sapphire Heat Sink

Once the seamless interface is established, the sapphire substrate can effectively perform its role as a heat sink.

Sapphire possesses high thermal conductivity, but it can only dissipate heat that successfully reaches it. The vacuum process ensures that thermal energy generated in the phosphor layer is immediately transferred to the sapphire, rather than accumulating in the ceramic.

Quantifiable Performance Gains

Drastic Reduction in Operating Temperatures

The impact of this thermal coupling is measurably significant.

Under identical high-power conditions, traditional pure ceramics can reach dangerous temperatures of approximately 439 °C. In contrast, composites treated with high-temperature vacuum processing maintain a much cooler operating temperature of around 146 °C.

Preventing Thermal Quenching

By keeping the material nearly 300 °C cooler, the composite avoids the phenomenon of thermal quenching.

Thermal quenching occurs when excessive heat degrades the phosphor's efficiency, causing light output to drop even as input power rises. This processing method ensures the material remains in a linear efficiency range, preventing brightness saturation.

Understanding the Trade-offs

Dependency on Substrate Choice

It is critical to note that the vacuum process is only as effective as the substrate it connects to.

The process creates the pathway for heat, but the substrate (in this case, sapphire) provides the capacity to absorb it. Using this processing method with a substrate that has low thermal conductivity would yield negligible benefits.

Manufacturing Complexity

Achieving a seamless interface requires precise control over vacuum levels and temperature profiles.

Unlike simple mechanical bonding or standard sintering, high-temperature vacuum processing adds a layer of complexity to the manufacturing workflow. It requires specialized equipment to ensure the interface is truly robust enough to handle high optical power densities.

Strategies for High-Power Applications

To maximize the lifespan and brightness of your laser-driven systems, consider the following based on your specific requirements:

- If your primary focus is Maximum Brightness: Utilize this composite structure to push optical power densities higher without hitting the saturation wall caused by overheating.

- If your primary focus is Thermal Stability: Rely on the seamless interface to maintain lower steady-state temperatures (near 146 °C), which preserves the material integrity over long operational cycles.

By effectively coupling the active ceramic layer to a thermal heat sink, you convert a fragile optical component into a robust, high-power emitter.

Summary Table:

| Feature | Pure Phosphor Ceramic | Vacuum-Processed Composite (Sapphire) |

|---|---|---|

| Operating Temp | ~439 °C | ~146 °C |

| Thermal Interface | High Resistance (Bottlenecks) | Seamless (Atomic-level contact) |

| Heat Dissipation | Limited to Ceramic Surface | Efficient Sapphire Heat Sink |

| Performance | Thermal Quenching / Saturation | Linear Efficiency / High Brightness |

Maximize Your Optical Performance with KINTEK

Don't let thermal quenching limit your laser-driven systems. Backed by expert R&D and manufacturing, KINTEK offers high-performance vacuum systems and customizable lab high-temperature furnaces—including Muffle, Tube, Rotary, Vacuum, and CVD systems—tailored to solve your most complex thermal management challenges. Whether you are developing advanced phosphor composites or high-power emitters, our equipment ensures the precision needed for a seamless interface. Contact our technical team today to discover how our custom solutions can enhance your material stability and lab efficiency!

Visual Guide

References

- Guoyu Xi, Daqin Chen. Transparent Ceramic@Sapphire Composites for High‐Power Laser‐Driven Lighting. DOI: 10.1002/advs.202505232

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

People Also Ask

- What are the key differences in maximum temperature between low vacuum and high vacuum furnaces? Unlock Higher Heat for Purity

- What are the key characteristics of high-temperature vacuum furnaces? Achieve Ultimate Purity and Precision in Material Processing

- What are the advantages of performing brazing in a vacuum environment? Achieve Clean, Strong Joints with Precision

- What are the size ranges and common applications of crucible furnaces? Find Your Perfect Fit for Small-Batch Melting

- What are the advantages of high vacuum furnaces? Achieve Ultimate Purity and Control

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Why is the selection of insulation layer materials critical for vacuum sintering furnace design? Boost Thermal Efficiency

- What is the function of a Vacuum Annealing Furnace in the ageing treatment of tungsten alloys? Maximize Material Strength