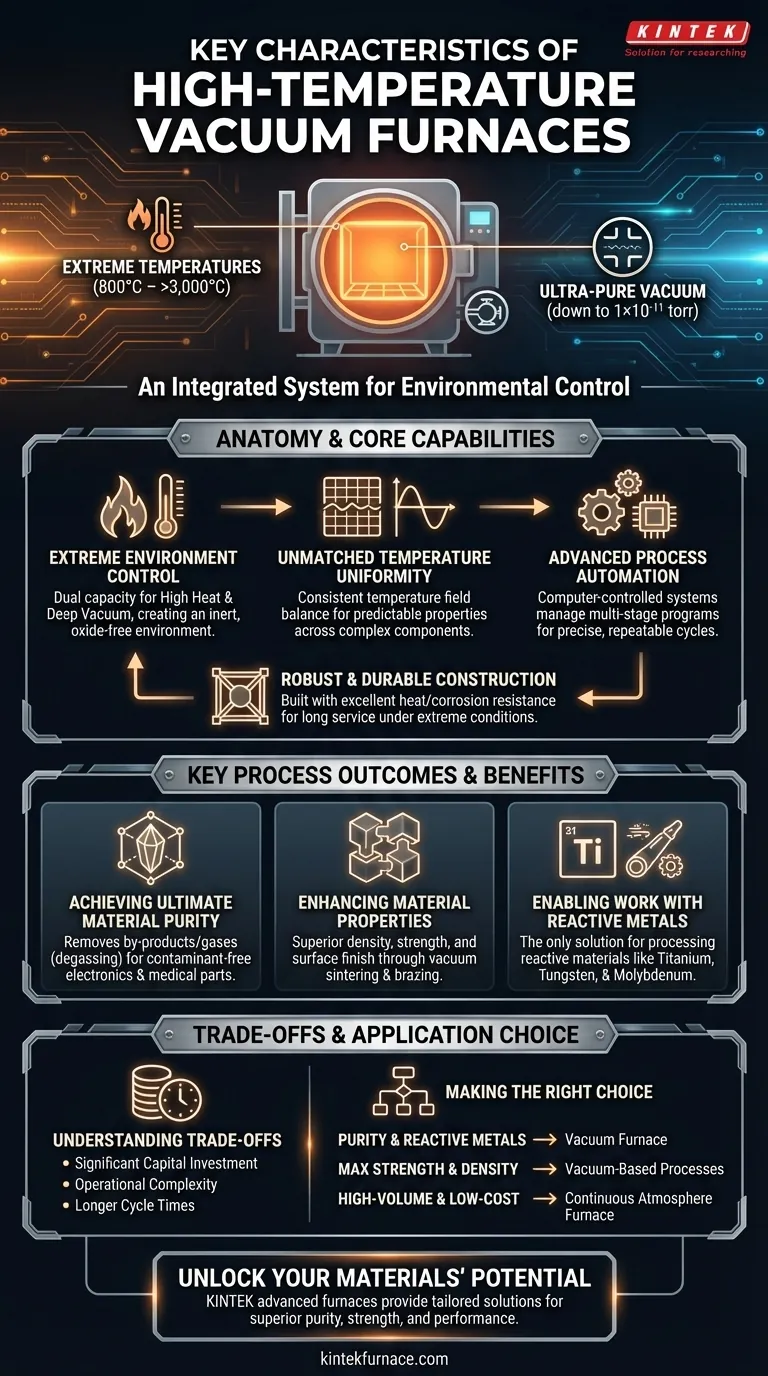

At their core, high-temperature vacuum furnaces are defined by their ability to achieve extreme temperatures, create an ultra-pure vacuum environment, and maintain precise, repeatable control over the entire process. They are engineered to operate in ranges from 800°C to over 3,000°C (1,500–5,400°F), removing atmospheric gases that would otherwise contaminate or react with sensitive materials during heating.

A high-temperature vacuum furnace is more than just an oven. It is a highly engineered environment designed to achieve material properties, purity levels, and surface finishes that are simply impossible in the presence of atmospheric gases.

The Anatomy of a High-Temperature Vacuum Furnace

To understand their value, you must look beyond the heat and see the furnace as an integrated system for environmental control. Its key characteristics work together to produce results unattainable by other means.

Extreme Environment Control

The dual capacity for high heat and deep vacuum is the foundational characteristic. Temperatures can exceed 3,000°C, while vacuum systems can pull levels down as low as 1×10−11 torr.

This combination creates an inert environment, preventing oxidation and other chemical reactions that would occur in a standard atmosphere furnace.

Unmatched Temperature Uniformity

These furnaces are designed for exceptional temperature field balance. This ensures that the temperature is consistent across the entire heated zone.

Uniformity is critical for treating complex components, guaranteeing that every section of the part receives the exact same thermal profile and thus achieves consistent, predictable material properties.

Advanced Process Automation

Modern vacuum furnaces are governed by computer-controlled systems that manage temperature, vacuum levels, and gas flow.

This allows for multi-stage programs that precisely control heating ramps, soak times, and rapid cooling or quenching. The result is unparalleled process repeatability, which is essential for quality control in critical industries.

Robust and Durable Construction

These systems are built for long service life under extreme conditions. They feature excellent heat and corrosion resistance, low thermal conductivity to maintain efficiency, and stable chemical properties to avoid polluting the workload.

Why This Environment Matters: Key Process Outcomes

The controlled environment of a vacuum furnace directly translates into superior results for demanding materials and applications.

Achieving Ultimate Material Purity

The vacuum actively removes by-products and entrapped gases from the material during heating, a process known as degassing.

This prevents contamination and results in a final product with significantly higher purity, which is crucial for electronics, medical implants, and research applications.

Enhancing Material Properties

Processes like vacuum sintering and vacuum brazing produce parts with superior physical characteristics. The absence of atmosphere allows for better particle adhesion and diffusion.

This results in finished components with higher density, greater strength, and an enhanced surface finish compared to parts processed in atmosphere.

Enabling Work with Reactive Metals

Many advanced materials are highly reactive with oxygen, especially at high temperatures.

A vacuum furnace is the only viable solution for processing reactive metals like titanium, tungsten, and molybdenum, which are fundamental to the aerospace and medical industries.

Understanding the Trade-offs

While powerful, these furnaces are a specialized tool. Understanding their limitations is key to making an informed decision.

Significant Capital Investment

The combination of high-temperature-rated materials, sophisticated vacuum pumps, and advanced control systems makes these furnaces a major capital expenditure.

Operational Complexity

These are not simple "set and forget" machines. They require skilled operators to manage processing cycles and rigorous maintenance protocols to keep the vacuum systems, seals, and heating elements in optimal condition.

Longer Cycle Times

Achieving a deep vacuum requires a "pump-down" phase before heating can begin. This, combined with controlled cooling cycles, often results in longer overall process times compared to conventional atmosphere furnaces, which can impact throughput.

Making the Right Choice for Your Application

Selecting a high-temperature vacuum furnace depends entirely on the specific demands of your material and final product.

- If your primary focus is material purity and processing reactive metals: A vacuum furnace is non-negotiable, as it provides the inert environment necessary to prevent oxidation and contamination.

- If your primary focus is achieving maximum strength and density: Vacuum-based processes like sintering and heat-treating offer superior metallurgical properties compared to conventional methods.

- If your primary focus is high-volume, low-cost treatment of common alloys: A simpler, continuous atmosphere furnace may be a more practical and cost-effective solution.

By understanding these core characteristics, you can determine when the precision and purity of a vacuum furnace are a necessary investment for your most demanding applications.

Summary Table:

| Characteristic | Description |

|---|---|

| Extreme Temperature Range | Operates from 800°C to over 3,000°C for high-heat applications |

| Deep Vacuum Environment | Achieves levels as low as 1×10⁻¹¹ torr to prevent oxidation and contamination |

| Temperature Uniformity | Ensures consistent heating across the entire zone for predictable results |

| Process Automation | Computer-controlled systems for precise, repeatable heating and cooling cycles |

| Robust Construction | Built with heat and corrosion-resistant materials for long service life |

| Material Purity Enhancement | Removes gases and by-products, ideal for reactive metals and sensitive materials |

| Operational Considerations | High capital investment, skilled operation required, and longer cycle times |

Unlock the full potential of your materials with KINTEK's advanced high-temperature vacuum furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior purity, strength, and performance. Contact us today to discuss how our furnaces can elevate your processes and deliver unmatched results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control