The primary advantage of vacuum brazing is its ability to produce exceptionally clean, strong, and consistent joints in a highly controlled environment. By performing the process in a vacuum, you prevent the formation of oxides on the metal surfaces, which eliminates the need for corrosive fluxes and subsequent cleaning steps. This results in a superior metallurgical bond with minimal residual stress and distortion.

Vacuum brazing is not merely a joining method; it is a precision manufacturing process. It trades the speed of simpler techniques for unparalleled control over the joint's purity, strength, and structural integrity, making it essential for high-performance applications.

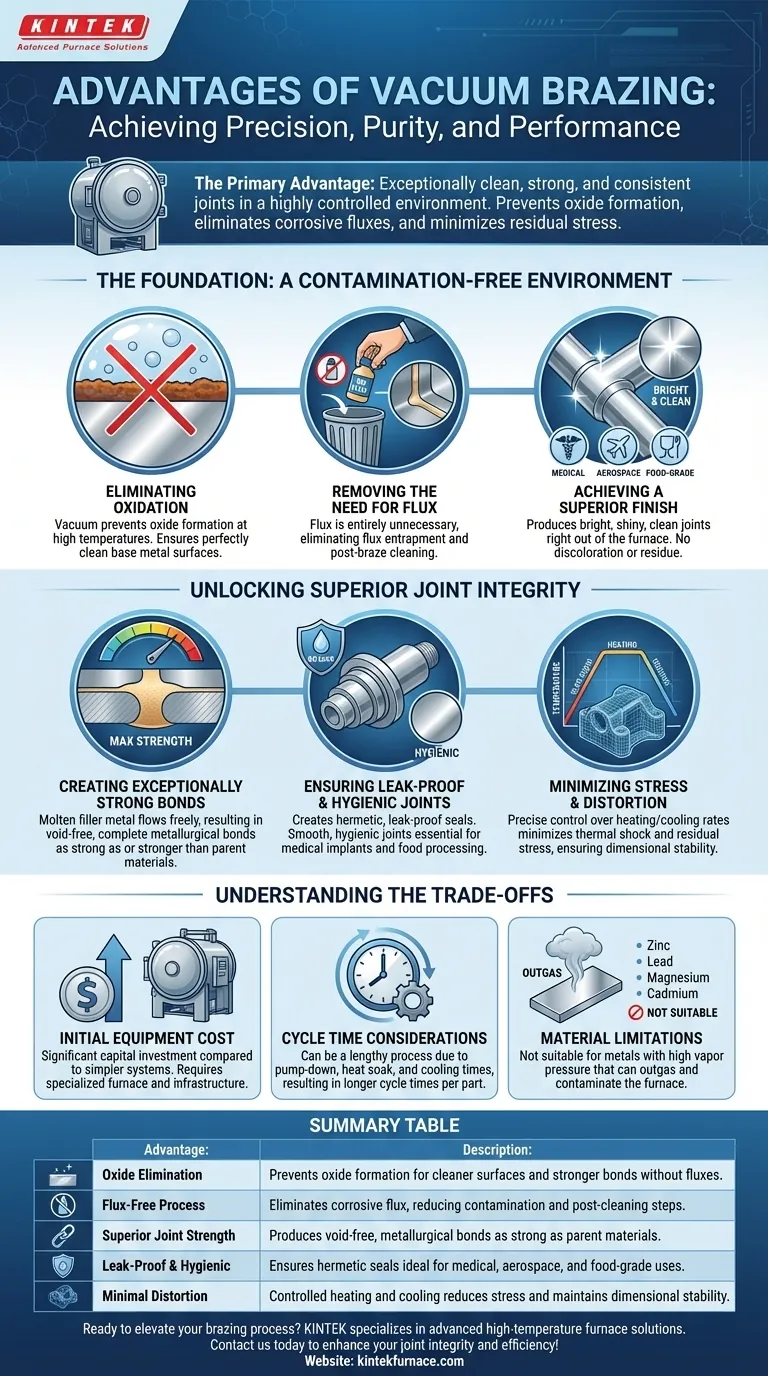

The Foundation: A Contamination-Free Environment

The core benefits of vacuum brazing all stem from one fundamental principle: removing the atmosphere from the process. This creates an ideal environment for forming a perfect metallurgical bond.

Eliminating Oxidation

In a normal atmosphere, heating metals causes them to react with oxygen, forming an oxide layer. This layer acts as a barrier, preventing the filler metal from properly wetting and bonding with the base materials.

A vacuum furnace removes virtually all oxygen, preventing oxide formation even at high temperatures. This ensures the base metal surfaces remain perfectly clean and ready for bonding.

Removing the Need for Flux

Traditional brazing methods rely on a chemical agent called flux to clean oxides from the joining surfaces. However, flux is corrosive and can become trapped in the joint, creating a weak point or a potential site for future corrosion.

Because vacuum brazing prevents oxides from forming in the first place, flux is entirely unnecessary. This eliminates the risk of flux entrapment and the need for post-braze cleaning operations.

Achieving a Superior Finish

The result of this fluxless, oxide-free process is an assembly with bright, shiny, and clean joints right out of the furnace. There is no discoloration or residue, making it the preferred method for medical, aerospace, and food-grade applications where cleanliness is paramount.

Unlocking Superior Joint Integrity

By controlling the environment, you gain precise control over the quality and physical properties of the final joint. This leads to performance characteristics that other methods cannot easily replicate.

Creating Exceptionally Strong Bonds

With perfectly clean surfaces, the molten brazing filler metal can flow freely into the joint gap through capillary action. This results in a void-free, complete metallurgical bond.

Vacuum-brazed joints are often as strong as, or even stronger than, the parent materials being joined. This high level of strength and reproducibility is critical for components that experience high stress.

Ensuring Leak-Proof and Hygienic Joints

The complete fill of the joint creates a hermetic, leak-proof seal. This is essential for components used in vacuum systems, high-pressure fluid applications, and electronics.

The absence of gaps or trapped flux also results in a smooth, hygienic joint, a non-negotiable requirement for medical implants and food processing equipment.

Minimizing Stress and Distortion

Vacuum furnaces allow for precise control over heating and cooling rates. The slow, uniform heating and controlled cooling of the entire assembly minimizes thermal shock and residual stress.

This leads to exceptional dimensional stability and minimal distortion, even when joining complex assemblies or parts with thick and thin cross-sections.

Understanding the Trade-offs

While powerful, vacuum brazing is not the universal solution for all joining tasks. Understanding its limitations is key to making an informed decision.

Initial Equipment Cost

Vacuum furnaces represent a significant capital investment compared to simpler torch, induction, or atmospheric furnace systems. The cost of the equipment and supporting infrastructure is a primary consideration.

Cycle Time Considerations

The process itself can be lengthy. While combining steps like hardening and brazing is a major efficiency gain, the required time to pump down the vacuum, heat soak, and cool the assembly can result in longer cycle times per part compared to flame brazing.

Material Limitations

Vacuum brazing is not suitable for all materials. Metals with a high vapor pressure, such as zinc, lead, magnesium, or cadmium, can outgas at high temperatures in a vacuum. This "boiling off" contaminates the furnace and can ruin the parts being brazed.

Making the Right Choice for Your Application

Selecting the right brazing method depends entirely on your project's specific requirements for performance, cost, and material compatibility.

- If your primary focus is maximum joint strength and purity: Vacuum brazing is unparalleled, as it eliminates the oxides and flux that compromise the integrity of a metallurgical bond.

- If your primary focus is process efficiency for complex assemblies: Vacuum brazing is ideal, allowing you to create multiple joints and perform heat treatment in a single, highly repeatable cycle.

- If your primary focus is joining sensitive or dissimilar materials: The precise thermal control of a vacuum furnace minimizes stress and distortion, enabling the successful joining of delicate components or materials like metal-to-ceramic.

Ultimately, choosing vacuum brazing is a decision to prioritize metallurgical perfection and process control above all other factors.

Summary Table:

| Advantage | Description |

|---|---|

| Oxide Elimination | Prevents oxide formation for cleaner surfaces and stronger bonds without fluxes. |

| Flux-Free Process | Eliminates corrosive flux, reducing contamination and post-cleaning steps. |

| Superior Joint Strength | Produces void-free, metallurgical bonds as strong as parent materials. |

| Leak-Proof and Hygienic | Ensures hermetic seals ideal for medical, aerospace, and food-grade uses. |

| Minimal Distortion | Controlled heating and cooling reduces stress and maintains dimensional stability. |

Ready to elevate your brazing process with precision and reliability? KINTEK specializes in advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, tailored for industries like aerospace, medical, and electronics. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs. Contact us today to discuss how our expertise can enhance your joint integrity and efficiency!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering