At its core, a vacuum heat treatment furnace prevents contamination by physically removing the atmosphere—air, moisture, and other gases—from the heating chamber. By creating a low-pressure environment, it eliminates the elements that would otherwise react with the material at high temperatures, preventing unwanted chemical changes like oxidation and ensuring the workpiece remains pure.

The fundamental advantage of a vacuum furnace is not the vacuum itself, but the chemically inert environment it creates. This control over the atmosphere is what protects a material's surface integrity and preserves its intrinsic properties during the intense heat treatment process.

The Core Principle: Removing the Reactive Atmosphere

The primary function of the vacuum is to create an environment where unwanted chemical reactions cannot occur. This is achieved by targeting the root cause of most contamination during heat treatment: the air around the part.

Eliminating Oxidation and Decarburization

At high temperatures, the oxygen in the air aggressively reacts with most metals, forming a layer of oxide scale on the surface. This not only ruins the part's finish but can alter its dimensions and properties.

A vacuum furnace pumps out nearly all of the oxygen, preventing this reaction. This results in parts that emerge from the furnace with a clean, bright finish, free from discoloration. Similarly, it prevents the loss of carbon from the surface of steels (decarburization).

Preventing Surface Contamination

The atmosphere contains more than just oxygen. Trace gases, moisture, and other impurities can also react with or embed themselves into a material's surface when it is heated.

By evacuating the chamber, these potential contaminants are removed. This ensures the finished product is chemically pure and free from transmutation or surface impurities that could compromise performance, especially in sensitive applications like medical implants or aerospace components.

The Process in Detail: Environment Control

A vacuum furnace provides a highly controlled environment that extends beyond just the heating phase. The cooling or quenching phase is just as critical for preventing contamination and achieving desired material properties.

Creating the Vacuum

The process begins by placing the workpiece inside the furnace chamber and sealing it. A series of pumps then removes the air and other gases, reducing the internal pressure to a near-perfect vacuum. This step ensures the reactive atmosphere is gone before any significant heat is applied.

The Role of Inert Gas for Cooling

While a vacuum is excellent for preventing reactions, it is a poor medium for transferring heat, which makes cooling a challenge. To cool the part rapidly and uniformly without introducing contaminants, the vacuum is often broken by backfilling the chamber with a high-purity inert gas.

Gases like argon or nitrogen are used because they do not react chemically with the hot material. This allows for rapid cooling through convection (gas quenching) while maintaining a clean, controlled environment.

Controlled Quenching Methods

For some processes, even faster cooling is required. Vacuum furnaces can be equipped with integrated quenching systems that use oil or even water. These operations are performed within the controlled system to minimize any exposure to the outside atmosphere, transitioning from a pure vacuum to a quenching medium without compromising the part's surface integrity.

Understanding the Trade-offs and Alternatives

While highly effective, vacuum technology is not the only solution for preventing contamination. Understanding its context helps clarify its unique advantages.

The Challenge of Outgassing

A powerful vacuum doesn't just remove the atmosphere around a part; it can also pull trapped gases and impurities out of the material itself. This process, known as outgassing, is a key feature of vacuum purification processes. However, it must be managed correctly to ensure these liberated gases don't contaminate the furnace or other parts in the load.

Alternative: The Muffle Furnace

An alternative method for preventing contamination is a muffle furnace. This design uses a physical barrier—an insulated inner chamber or "muffle"—to isolate the workpiece from the combustion gases of the heat source.

While a muffle furnace effectively prevents contamination from combustion byproducts, it does not remove the air from within the muffle. Therefore, it does not protect against the oxidation that a vacuum furnace is specifically designed to eliminate.

Making the Right Choice for Your Goal

The decision to use a vacuum furnace is driven by the need for ultimate control over the material's surface and chemical purity.

- If your primary focus is a bright, scale-free finish: A vacuum furnace is the definitive solution, as it removes the oxygen responsible for oxidation.

- If your primary focus is high-purity brazing or sintering: The ultra-clean environment of a vacuum prevents impurities from interfering with metallurgical bonds.

- If your primary focus is achieving specific hardness without surface changes: Combining vacuum heating with controlled inert gas or oil quenching provides precise results without decarburization or oxidation.

Ultimately, a vacuum furnace provides an unparalleled level of atmospheric control, ensuring that the only changes made to a material are the ones you intend.

Summary Table:

| Prevention Method | Key Benefit |

|---|---|

| Removes oxygen and gases | Prevents oxidation and decarburization, ensuring bright finish |

| Uses inert gas for cooling | Maintains purity during rapid quenching without contamination |

| Eliminates moisture and impurities | Preserves material integrity for sensitive applications |

Need a contamination-free heat treatment solution? KINTEK specializes in advanced high-temperature furnaces, including Vacuum & Atmosphere Furnaces, tailored for industries like aerospace and medical devices. Leveraging our strong R&D and deep customization capabilities, we ensure your materials achieve superior purity and performance. Contact us today to discuss how our solutions can meet your unique requirements!

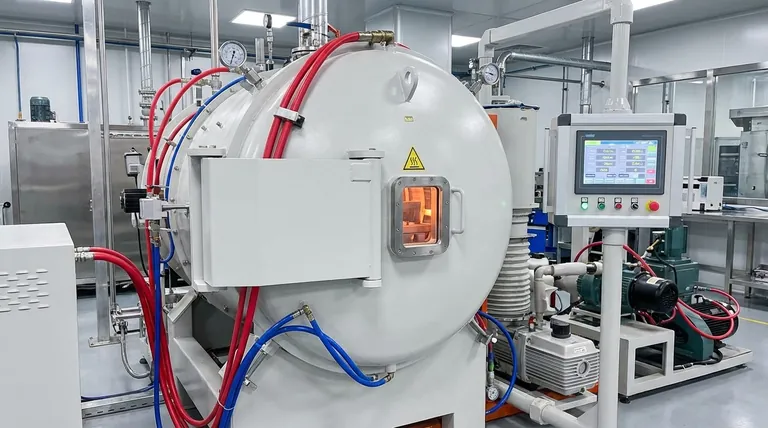

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control