In essence, a vacuum furnace is a specialized type of furnace that performs high-temperature processes inside a chamber from which the air has been removed. By creating a vacuum, it protects materials like metals and ceramics from oxidation, contamination, and other unwanted chemical reactions that occur in a normal atmosphere. This controlled environment enables higher-quality outcomes that are impossible to achieve with conventional heating methods.

The core problem with heating materials in air is that the atmosphere itself becomes a reactive contaminant. A vacuum furnace solves this by removing the atmosphere, providing an ultra-pure environment for processes like heat treating, brazing, and sintering.

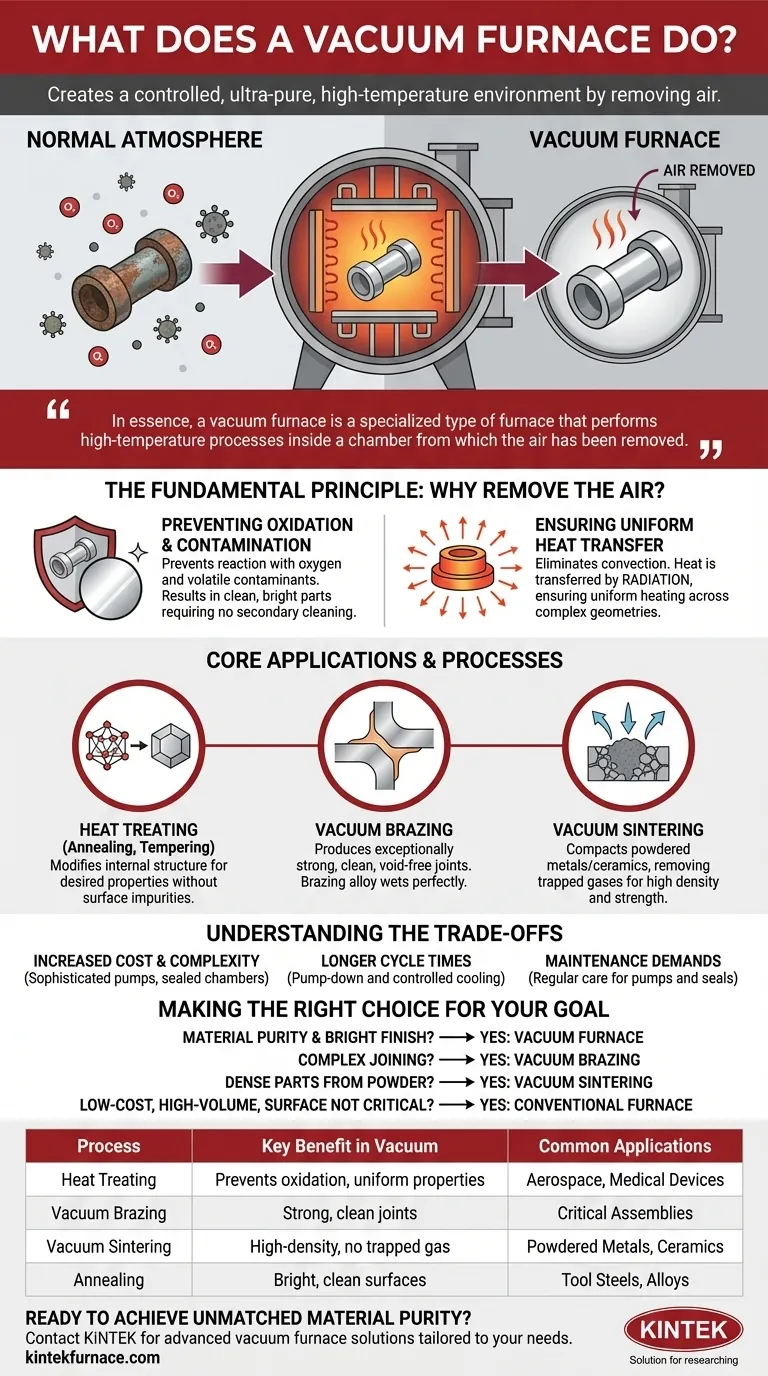

The Fundamental Principle: Why Remove the Air?

A vacuum furnace's primary function is not just to heat, but to create a precisely controlled environment. Removing the atmosphere is the key to unlocking several critical advantages.

Preventing Oxidation and Contamination

At high temperatures, most metals react aggressively with oxygen in the air, forming a layer of oxide scale. This scale can compromise the material's dimensions, surface finish, and structural integrity.

A vacuum furnace removes the oxygen, preventing this reaction entirely. This results in clean, bright parts that often require no secondary cleaning operations. The vacuum also pulls out other volatile contaminants from the material's surface, leading to exceptional purity.

Ensuring Uniform Heat Transfer

In a conventional furnace, heat is transferred through convection (air currents), conduction, and radiation. Air currents can cause uneven heating, creating hot and cold spots on a part.

In a vacuum, convection is eliminated. Heat is transferred almost entirely by radiation, which travels in a straight line from the heating elements to the material. This results in highly uniform and predictable heating across the entire part, which is critical for complex geometries and achieving consistent material properties.

Core Applications and Processes

The unique environment inside a vacuum furnace makes it essential for several high-performance industrial processes.

Heat Treating (Annealing, Tempering, Quenching)

These processes modify a metal's internal crystal structure to achieve desired properties like hardness, strength, or ductility.

Performing these treatments in a vacuum ensures the intended metallurgical changes happen precisely, without introducing surface impurities or internal defects from atmospheric reactions.

Vacuum Brazing

Brazing is a process for joining two or more metal items by melting and flowing a filler metal into the joint.

Vacuum brazing produces exceptionally strong, clean, and void-free joints. The vacuum allows the brazing alloy to wet and flow perfectly into the joint, uninhibited by the oxides that would form in air. This is essential for aerospace, medical, and other critical applications.

Vacuum Sintering

Sintering is the process of compacting and forming a solid mass of material by heat, without melting it to the point of liquefaction. It is commonly used for powdered metals and ceramics.

Using a vacuum for sintering is critical for removing trapped gases between the powder particles. This results in a final part with higher density, superior strength, and better overall integrity.

Understanding the Trade-offs

While powerful, a vacuum furnace is a specialized tool with specific considerations. It is not the right choice for every heating application.

Increased Cost and Complexity

Vacuum furnaces are mechanically complex. They require robust sealed chambers, sophisticated pumping systems (roughing pumps and high-vacuum pumps), and precise instrumentation. This makes their initial acquisition cost significantly higher than atmospheric furnaces.

Longer Cycle Times

Achieving a deep vacuum is not instantaneous. The "pump-down" time to evacuate the chamber adds to the total process cycle. Likewise, cooling is often more controlled and can take longer than simply opening a door to the air.

Maintenance Demands

The vacuum system, including pumps, valves, and seals, requires regular and specialized maintenance to function correctly. Even a small leak can compromise the vacuum level and ruin an entire batch of expensive components.

Making the Right Choice for Your Goal

Selecting the correct heating technology depends entirely on the requirements of your material and the desired final outcome.

- If your primary focus is material purity and a bright surface finish: A vacuum furnace is non-negotiable to prevent the oxidation and scaling that occurs in air.

- If your primary focus is joining complex or mission-critical components: Vacuum brazing provides unparalleled joint strength, cleanliness, and reliability.

- If your primary focus is creating dense, high-strength parts from powders: Vacuum sintering is essential for removing trapped gases and achieving superior material properties.

- If your primary focus is low-cost, high-volume heat treatment where surface finish is not critical: A conventional atmospheric furnace may be a more cost-effective solution.

Ultimately, a vacuum furnace provides an unparalleled level of process control, making it an essential tool for manufacturing the highest quality modern materials and components.

Summary Table:

| Process | Key Benefit in Vacuum | Common Applications |

|---|---|---|

| Heat Treating | Prevents oxidation, ensures uniform material properties | Aerospace components, medical devices |

| Vacuum Brazing | Creates exceptionally strong, clean joints | Critical assemblies, complex geometries |

| Vacuum Sintering | Removes trapped gases for high-density parts | Powdered metals, advanced ceramics |

| Annealing | Produces bright, clean surfaces without scaling | Tool steels, specialty alloys |

Ready to Achieve Unmatched Material Purity and Performance?

Your research and manufacturing processes demand the highest quality outcomes. KINTEK's advanced vacuum furnace solutions provide the precise, contamination-free environment essential for success in heat treating, brazing, and sintering.

Why choose KINTEK?

- Expertise & Customization: We leverage exceptional R&D and in-house manufacturing to tailor our vacuum furnaces to your unique experimental and production requirements.

- Comprehensive Product Line: From standard models to highly specialized systems, we have the right solution for your lab or production facility.

- Proven Performance: Our furnaces are trusted for critical applications where material integrity is paramount.

Let's discuss how a KINTEK vacuum furnace can solve your specific material processing challenges. Contact our experts today for a personalized consultation.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision