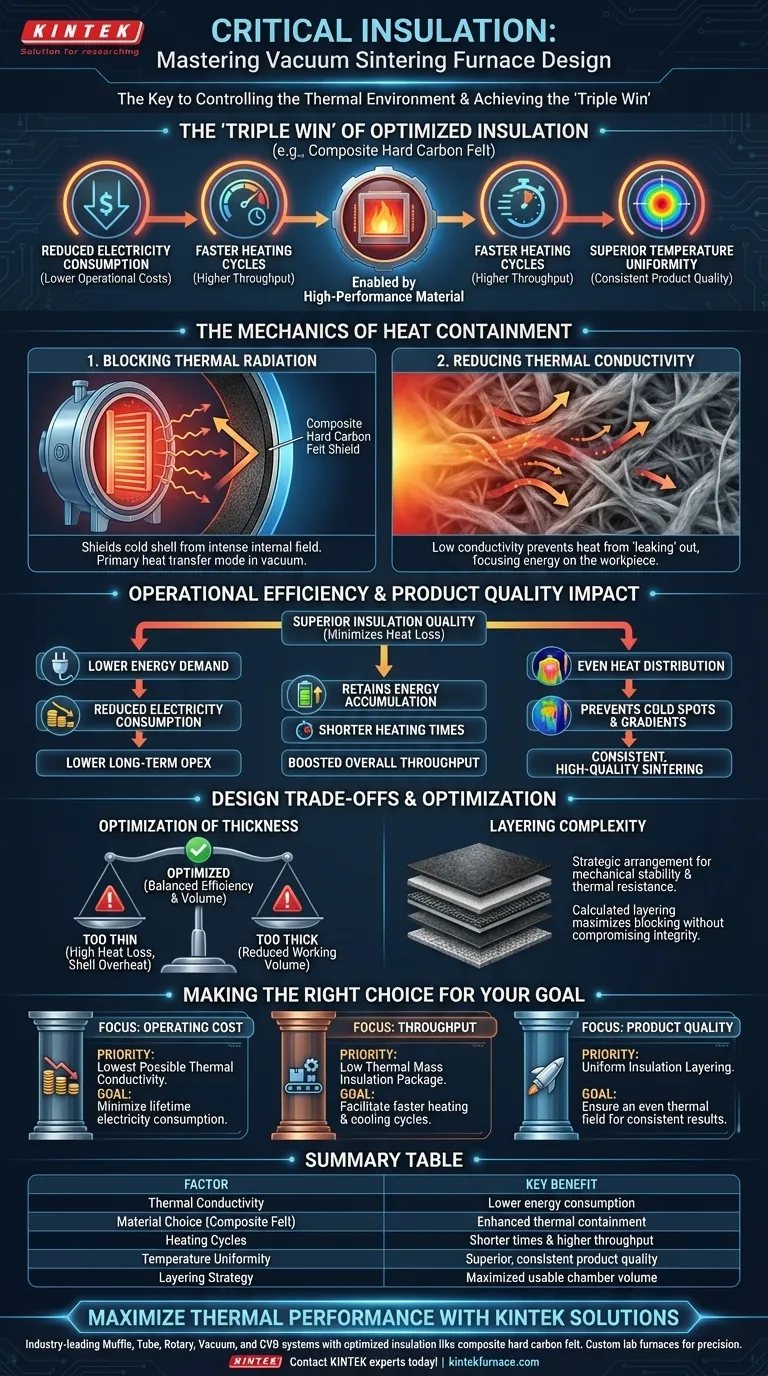

The selection of the insulation layer is the single most significant factor in controlling the thermal environment of a vacuum sintering furnace. It directly dictates the furnace's ability to retain heat, maintain consistent internal temperatures, and operate within a viable energy budget. Without high-performance materials like composite hard carbon felt, the system suffers from excessive radiant heat loss to the outer shell.

The insulation layer acts as the primary barrier against radiant heat loss. By optimizing materials like composite hard carbon felt to lower thermal conductivity, you achieve a "triple win": reduced electricity consumption, faster heating cycles, and superior temperature uniformity for the sintered product.

The Mechanics of Heat Containment

Blocking Thermal Radiation

In a vacuum environment, heat transfer occurs primarily through radiation rather than convection. The insulation layer acts as a shield between the intense internal thermal field and the cold furnace shell.

High-performance materials like composite hard carbon felt are essential because they effectively block this radiative transfer.

Reducing Thermal Conductivity

The core physical property at play is thermal conductivity. The lower the conductivity of your insulation material, the more effective it is at trapping heat.

By selecting materials known for low thermal conductivity, you prevent heat from "leaking" out of the processing zone. This ensures that the energy you input stays focused on the workpiece, rather than dissipating into the furnace structure.

Operational Efficiency and Cost

Lowering Electricity Consumption

Efficiency is a direct function of insulation quality. When the insulation layer successfully minimizes heat loss, the furnace requires significantly less power to maintain high temperatures.

This reduction in energy demand lowers immediate electricity consumption, reducing the long-term operational costs of the facility.

Shortening Heating Times

Poor insulation forces the heating elements to work harder to combat constant energy loss. Conversely, superior insulation allows the system to retain energy accumulation.

This results in shorter heating times, allowing the furnace to reach its target temperature faster. This efficiency boosts overall throughput by reducing the total cycle time.

Impact on Product Quality

Achieving Temperature Uniformity

For high-stakes applications, such as sintering carbon composites for aerospace, consistency is non-negotiable.

A well-designed insulation layer ensures that heat is distributed evenly throughout the chamber. This temperature uniformity prevents "cold spots" or gradients that could lead to structural weaknesses or uneven sintering in the final product.

Understanding the Design Trade-offs

Optimization of Thickness

While insulation is critical, simply adding more material is not always the solution. The insulation layer must be optimized for thickness.

If the layer is too thin, heat loss remains high, and the outer shell may overheat. If it is too thick, you may unnecessarily reduce the usable working volume of the furnace.

Layering Complexity

Effective insulation often requires strategic layering. The arrangement of the composite hard carbon felt affects its mechanical stability and thermal resistance.

Engineers must calculate the precise layering strategy to maximize radiation blocking without compromising the structural integrity of the insulation pack itself.

Making the Right Choice for Your Goal

When designing or selecting a vacuum sintering furnace, your priorities will dictate your insulation strategy:

- If your primary focus is Operating Cost: Prioritize materials with the lowest possible thermal conductivity to minimize electricity consumption over the machine's lifespan.

- If your primary focus is Throughput: Select an insulation package optimized for low thermal mass to facilitate faster heating and cooling cycles.

- If your primary focus is Product Quality: Focus on the uniformity of the insulation layering to ensure an even thermal field for consistent sintering results.

The insulation layer is not just a passive barrier; it is the active component that defines the thermal precision and economic viability of your furnace.

Summary Table:

| Factor | Impact on Furnace Performance | Key Benefit |

|---|---|---|

| Thermal Conductivity | Reduces radiant heat loss to the outer shell | Lower energy consumption |

| Material Choice | Use of composite hard carbon felt | Enhanced thermal containment |

| Heating Cycles | Faster accumulation of internal energy | Shorter cycle times & higher throughput |

| Temperature Uniformity | Eliminates thermal gradients and cold spots | Superior, consistent product quality |

| Layering Strategy | Optimized thickness and structural arrangement | Maximized usable chamber volume |

Maximize Your Thermal Performance with KINTEK

Don't let inefficient insulation drain your resources. KINTEK provides industry-leading vacuum furnace solutions engineered for precision and durability. Backed by expert R&D and world-class manufacturing, we offer a full range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all featuring optimized insulation like composite hard carbon felt to ensure peak energy efficiency and temperature uniformity.

Whether you need a standard setup or a fully customized lab furnace for unique high-temperature applications, our engineering team is ready to help you reduce operational costs and boost throughput.

Ready to upgrade your lab's capabilities?

Contact KINTEK experts today to discuss your custom sintering requirements!

Visual Guide

References

- Mao Li, Hesong Li. Numerical simulation of the heating process in a vacuum sintering electric furnace and structural optimization. DOI: 10.1038/s41598-024-81843-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are some applications of vacuum brazing? Achieve Strong, Clean Joints in Aerospace and More

- What role does a vacuum annealing furnace play in Carbon Onion synthesis? Achieve Precise Nano-Phase Transformation

- How do vacuum furnaces support research and development? Unlock Pure, Controlled Environments for Breakthroughs

- What are the applications of furnace brazing in the energy and power generation sector? Achieve Superior Joint Integrity for Critical Components

- Why is a high vacuum environment necessary during the SPS of CoCrFeMnNi alloy powders? Ensure Purity and Density

- What is a vacuum furnace? Precision Heating for Purity and Performance

- What key experimental environments do vacuum resistance furnaces provide for Ti–50Zr alloys? Ensure Material Purity

- How does the annealing furnace process work? Master Material Softening and Stress Relief