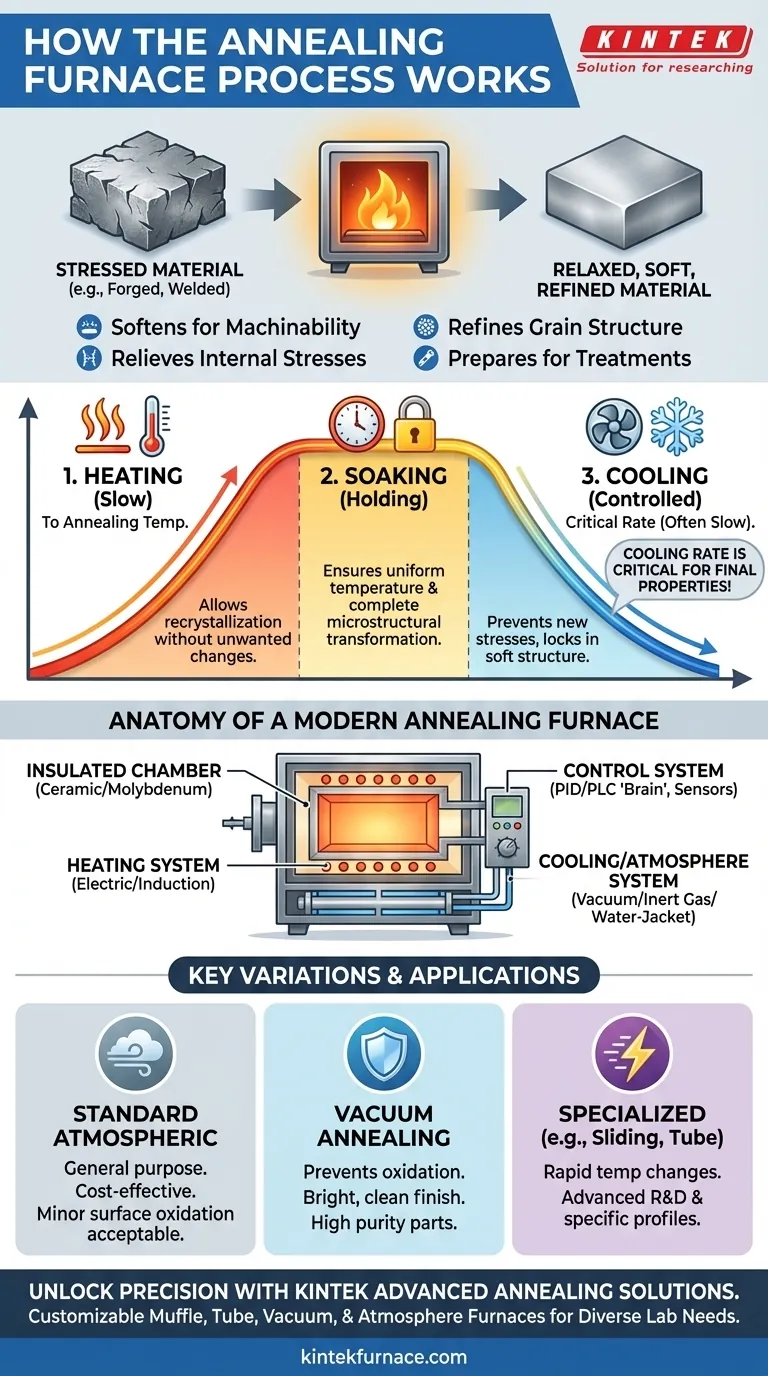

In essence, an annealing furnace is a specialized oven that precisely controls a three-stage thermal process: heating, holding, and cooling. This process fundamentally alters a material's internal microstructure, not to harden it, but to relieve internal stresses, increase its softness and ductility, and refine its grain structure. It is a critical step in manufacturing to make metals more workable and less prone to failure.

Annealing isn't simply heating metal; it's a precise, three-stage thermal process designed to reverse the stresses of manufacturing. This controlled cycle of heating, soaking, and cooling resets the material's internal structure, making it softer, more uniform, and less prone to future failure.

The Core Purpose: Reversing Manufacturing Stress

The primary goal of annealing is to improve a material's properties after it has undergone stressful processes like casting, forging, or rolling. This heat treatment addresses several key objectives.

Soften Materials for Machinability

Work-hardening makes metals tough and difficult to cut or shape. Annealing softens the material, making subsequent machining processes faster, easier, and less demanding on cutting tools.

Relieve Internal Stresses

Processes like welding, casting, and forging create significant residual stress within a material. If left untreated, this stress can lead to spontaneous deformation or cracking over time. Annealing allows the material's atomic structure to relax into a lower-energy state, effectively eliminating these internal stresses.

Refine Grain Structure

Annealing refines and homogenizes the crystalline structure (grains) of the metal. This results in improved mechanical properties, such as increased ductility (the ability to deform without fracturing) and toughness.

Prepare for Subsequent Treatments

For some alloys, annealing is a preparatory step. It creates a uniform and predictable microstructure that ensures a consistent and effective response to final heat treatments like quenching and tempering.

Deconstructing the Annealing Cycle

The effectiveness of annealing depends entirely on the precise control of three distinct stages.

Stage 1: Heating

The material is slowly heated in the furnace to a specific annealing temperature. This temperature is critical; it must be high enough to allow the material’s atomic structure to recrystallize and reform, but not so high that it causes unwanted phase changes or grain growth.

Stage 2: Soaking (Holding)

Once the target temperature is reached, it is held constant for a set period. This "soaking" phase ensures that the entire workpiece, from its surface to its core, achieves a uniform temperature and that the necessary microstructural changes have time to complete.

Stage 3: Cooling

The cooling rate is arguably the most critical variable in determining the final properties of the metal. The material is cooled at a suitable rate, which is often very slow (e.g., leaving the part to cool down inside the furnace). This slow cooling prevents new stresses from forming and allows the desired soft, refined grain structure to lock into place.

Anatomy of a Modern Annealing Furnace

While designs vary, most annealing furnaces share a set of core components that enable this precise thermal control.

The Furnace Chamber

This is the insulated enclosure where the workpiece is placed. It is often constructed from high-performance materials like ceramic fiber, molybdenum, or graphite to withstand extreme temperatures and ensure thermal efficiency.

The Heating System

Electric resistance elements, such as heating wires or silicon carbide (SiC) rods, are the most common heat source. Some specialized furnaces use medium-frequency induction coils, which generate heat directly within a crucible through thermal radiation.

The Control System (The Brain)

This is the heart of the process. A PID (Proportional-Integral-Derivative) or PLC (Programmable Logic Controller) system uses temperature sensors (thermocouples) to monitor the furnace in real time. It automatically adjusts the heating power to precisely follow the programmed temperature profile for heating, soaking, and cooling.

The Cooling and Atmospheric System

Cooling can be achieved by simply turning off the heaters and letting the furnace cool naturally. For faster or more controlled cycles, systems may use inert gas circulation or integrated water-cooling jackets. Many furnaces also feature a vacuum system to remove air and prevent oxidation on the material's surface.

Key Variations and Their Applications

Not all annealing is the same. The furnace type and process are chosen based on the material and the desired outcome.

Standard Atmospheric Annealing

This is the most common form, performed in a standard furnace with a normal air atmosphere. It is cost-effective and suitable for general-purpose stress relief and softening where minor surface oxidation is acceptable.

Vacuum Annealing

Here, the entire process occurs in a high-vacuum environment created by a series of pumps. The primary benefit is preventing oxidation and contamination, resulting in a clean, bright surface finish. This is critical for reactive metals or parts requiring high surface purity.

Specialized Furnaces

For cutting-edge applications, unique furnace designs exist. Sliding furnaces can move between heating and cooling zones to achieve extremely rapid temperature changes, useful for advanced materials research. Tube furnaces often use induction heating for very high and localized temperatures.

Selecting the Right Annealing Process

Your choice of annealing process depends directly on the final requirements for your material.

- If your primary focus is maximum ductility and stress relief: A standard annealing process with a slow, controlled furnace cool is the most effective and economical choice.

- If your primary focus is a high-purity, bright surface finish: Vacuum annealing is necessary to prevent any surface oxidation or discoloration during the heating cycle.

- If your primary focus is advanced materials research or rapid cycling: A specialized furnace, such as a sliding or induction tube furnace, may be required to achieve specific heating and cooling rates.

Ultimately, understanding the annealing process empowers you to control a material's properties with precision, ensuring it is perfectly suited for its final application.

Summary Table:

| Stage | Purpose | Key Details |

|---|---|---|

| Heating | Raise material to annealing temperature | Slow heating to allow recrystallization without unwanted changes |

| Soaking | Hold temperature uniformly | Ensures complete microstructural transformation throughout the workpiece |

| Cooling | Control final material properties | Slow cooling to prevent new stresses and lock in soft, refined grains |

Unlock Precision in Your Laboratory with KINTEK's Advanced Annealing Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Whether you need standard annealing for stress relief, vacuum annealing for high-purity finishes, or specialized systems for rapid cycling, we deliver reliable performance tailored to your needs. Enhance your material processing with our expertise—contact us today to discuss how we can optimize your annealing processes and boost efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- Why is a double-chamber device preferred over a standard electric furnace for sintering? Achieve Oxidation-Free Results

- What role does a vacuum sintering furnace play in the formation of the 'core-rim' structure in Ti(C,N)-FeCr cermets?

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance