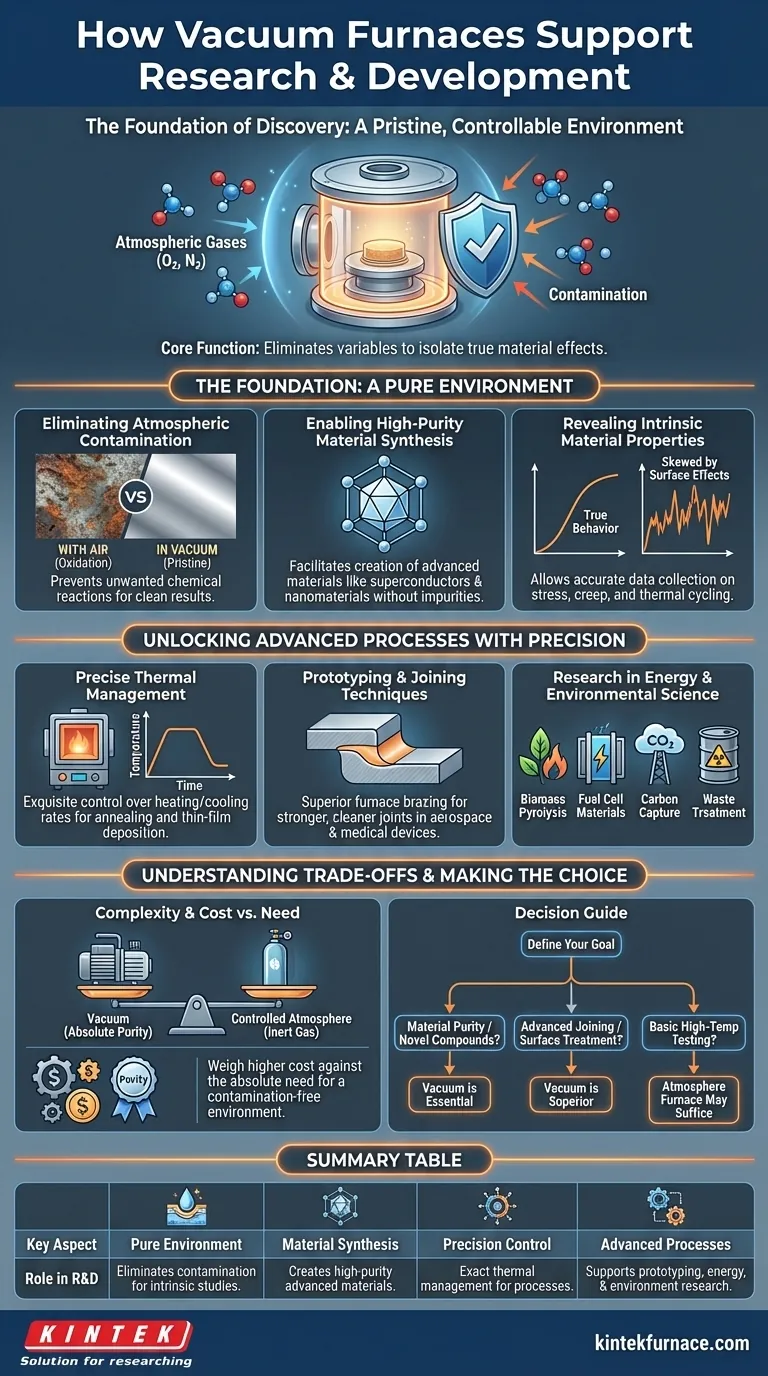

At its core, a vacuum furnace supports research and development by creating an extremely pure, highly controllable environment. This allows researchers to heat materials without the interference of atmospheric gases like oxygen or nitrogen, enabling them to study the intrinsic properties of materials, develop novel high-purity substances, and perfect advanced manufacturing processes with precision and repeatability.

The true value of a vacuum furnace in an R&D setting is not simply the high heat it generates. Its primary function is to eliminate atmospheric variables, providing a pristine stage where the true effects of temperature on a material can be isolated and understood.

The Foundation of R&D: A Pure Environment

The defining feature of a vacuum furnace is its ability to remove the atmosphere. This single capability is the reason it is indispensable for a wide range of research applications.

Eliminating Atmospheric Contamination

At high temperatures, most materials are highly reactive with the gases in the air we breathe. Oxygen, in particular, causes oxidation, which fundamentally changes a material's surface and structural properties.

A vacuum furnace pumps out these reactive gases. This prevents unwanted chemical reactions, ensuring that the results of an experiment are due to the material's response to heat alone, not contamination.

Enabling High-Purity Material Synthesis

The creation of advanced materials, such as superconductors, specific alloys, or nanomaterials, often demands exceptional purity. Even trace amounts of oxygen or nitrogen can disrupt their formation and degrade their performance.

By providing a high-vacuum, high-temperature environment, the furnace facilitates the formation and growth of these materials, ensuring their composition meets the exact specifications required for cutting-edge applications.

Revealing Intrinsic Material Properties

To truly understand a material, you must study it in its pure form. A vacuum environment allows researchers to conduct tests—such as thermal cycling, stress testing, and creep analysis—without the results being skewed by surface oxidation or nitriding.

This allows for the collection of clean, repeatable data on a material's true behavior, which is critical for accurate modeling and engineering.

Unlocking Advanced Processes with Precision Control

Beyond purity, vacuum furnaces offer an unparalleled level of control over the entire thermal process, which is essential for developing new techniques and prototypes.

Precise Thermal Management

Modern vacuum furnaces provide exquisite control over heating rates, soaking times, and cooling rates. This is vital for processes like annealing, which alters a material's microstructure to improve ductility or reduce hardness.

The ability to program complex temperature gradients and zones is also key for research into processes like thin-film deposition and uniform nanoparticle growth.

Prototyping and Joining Techniques

Furnace brazing is a common R&D application where parts are joined using a filler metal in the furnace. Performing this process in a vacuum is superior because it prevents the formation of oxides on the joint surfaces.

This results in stronger, cleaner, and more reliable joints. Researchers use this capability to test new component designs and develop advanced joining methods for industries like aerospace and medical devices.

Research in Energy and Environmental Science

Vacuum furnaces are critical tools in developing solutions for global challenges. They are used for:

- Biomass Pyrolysis: Heating organic matter in the absence of oxygen to produce biofuels.

- Fuel Cell Materials: Preparing and testing the highly sensitive materials used in next-generation fuel cells.

- Carbon Capture: Studying new materials and processes designed to capture and store CO2.

- Waste Treatment: Developing high-temperature pyrolysis methods for safely disposing of hazardous waste, such as nuclear fuel byproducts.

Understanding the Trade-offs

While powerful, a vacuum furnace is not the only thermal processing tool, and its use involves specific considerations.

Vacuum vs. Controlled Atmosphere

A vacuum is the removal of atmosphere. In some R&D scenarios, however, the goal is not a vacuum but a specific, controlled atmosphere using an inert gas like Argon or a reactive gas like Nitrogen.

While many vacuum furnaces can be backfilled with a specific gas, a simpler and more cost-effective "atmosphere furnace" may be sufficient if a high vacuum is never required for your research.

Complexity and Cost

The components required to achieve and maintain a high vacuum—including pumps, seals, and gauges—add significant cost and complexity compared to a standard muffle or atmosphere furnace.

The decision to invest in a vacuum furnace must be weighed against the absolute need for a contamination-free environment in your specific research goals.

Making the Right Choice for Your Research

To determine if a vacuum furnace is the correct tool, you must first define the level of environmental control your work demands.

- If your primary focus is material purity and developing novel compounds: A vacuum furnace is essential to prevent unwanted reactions and achieve the highest-purity results.

- If your primary focus is developing advanced joining or surface treatments: A vacuum furnace is the superior choice for creating clean, strong, oxide-free bonds and surfaces.

- If your primary focus is simply high-temperature testing in a stable environment: A more cost-effective atmosphere or muffle furnace may be sufficient, provided that potential atmospheric reactions will not compromise your data.

Ultimately, choosing the right furnace is about matching the tool's capabilities to the fundamental requirements of your scientific inquiry.

Summary Table:

| Key Aspect | Role in R&D |

|---|---|

| Pure Environment | Eliminates atmospheric gases to prevent contamination and oxidation, enabling intrinsic material studies. |

| Material Synthesis | Facilitates creation of high-purity materials like superconductors and alloys for advanced applications. |

| Precision Control | Allows exact management of heating/cooling rates for processes like annealing and thin-film deposition. |

| Advanced Processes | Supports prototyping, brazing, and research in energy, environmental science, and waste treatment. |

Ready to elevate your R&D with precision and purity? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're developing novel materials, prototyping components, or conducting high-purity experiments, our furnaces ensure contamination-free environments and precise thermal control to accelerate your breakthroughs. Contact us today to discuss how we can support your research goals!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance