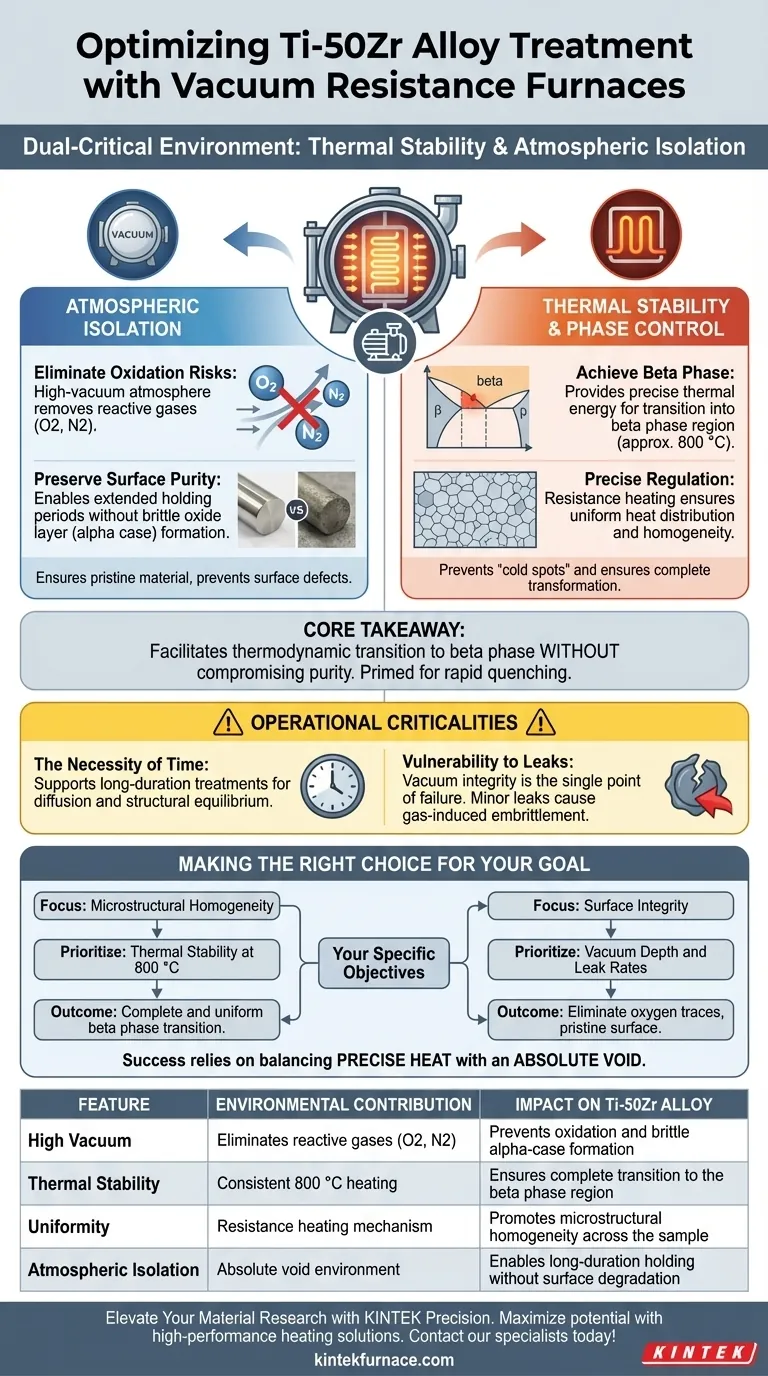

Vacuum resistance furnaces provide a dual-critical environment: thermal stability and atmospheric isolation. Specifically, they maintain a stable high temperature (typically around 800 °C) while simultaneously establishing a high-vacuum atmosphere to completely prevent oxidation during the solution treatment of Ti–50Zr alloys.

Core Takeaway The primary function of this environment is to facilitate a thermodynamic transition into the beta phase region without compromising the material's purity. By eliminating oxygen during extended holding periods, the furnace ensures the alloy's microstructure is primed for rapid quenching, free from surface degradation or embrittlement.

The Role of Atmospheric Isolation

Eliminating Oxidation Risks

The most critical environmental feature provided is a high-vacuum atmosphere. Ti–50Zr alloys contain highly reactive elements that chemically bond with oxygen and nitrogen almost instantly at elevated temperatures.

Preserving Surface Purity

By removing reactive gases, the furnace allows for extended holding periods without the formation of a brittle oxide layer (alpha case). This ensures that the material remains pristine, preventing surface defects that could initiate cracks or reduce mechanical performance.

Thermal Stability and Phase Control

Achieving the Beta Phase

The furnace provides the precise thermal energy required to drive the alloy's microstructure into the beta phase region. This is the foundational state necessary for the desired properties to be locked in during subsequent cooling steps.

Precise Temperature Regulation

Maintaining a stable temperature, such as 800 °C, is essential for homogeneity. The resistance heating mechanism ensures uniform heat distribution, preventing "cold spots" where the phase transformation might remain incomplete.

Operational Criticalities and Constraints

The Necessity of Time

The environment is designed to support long-duration solution treatments. Unlike rapid heating methods, this environment is optimized for equilibrium, allowing sufficient time for diffusion and structural changes to occur at the atomic level.

Vulnerability to Leaks

Because the process relies entirely on the absence of atmosphere, vacuum integrity is the single point of failure. Even minor leaks during the high-temperature hold can lead to gas-induced embrittlement, effectively ruining the alloy's ductility.

Making the Right Choice for Your Goal

When configuring your experimental setup for Ti–50Zr solution treatment, consider your specific objectives:

- If your primary focus is Microstructural Homogeneity: prioritize thermal stability at 800 °C to ensure a complete and uniform transition to the beta phase.

- If your primary focus is Surface Integrity: prioritize vacuum depth and leak rates to eliminate any trace of oxygen during the extended holding period.

Ultimately, the success of the treatment relies on balancing precise heat with an absolute void.

Summary Table:

| Feature | Environmental Contribution | Impact on Ti–50Zr Alloy |

|---|---|---|

| High Vacuum | Eliminates reactive gases (O2, N2) | Prevents oxidation and brittle alpha-case formation |

| Thermal Stability | Consistent 800 °C heating | Ensures complete transition to the beta phase region |

| Uniformity | Resistance heating mechanism | Promotes microstructural homogeneity across the sample |

| Atmospheric Isolation | Absolute void environment | Enables long-duration holding without surface degradation |

Elevate Your Material Research with KINTEK Precision

Maximize the potential of your Ti–50Zr alloys with high-performance heating solutions. Backed by expert R&D and manufacturing, KINTEK offers specialized Vacuum, Muffle, Tube, and CVD systems designed to meet the rigorous demands of solution treatments. Whether you require superior vacuum integrity to prevent embrittlement or precise thermal regulation for phase transitions, our customizable lab furnaces are built to your unique specifications.

Ready to ensure the purity and performance of your advanced materials?

Contact our specialists today to find your perfect furnace solution!

Visual Guide

References

- Improved Strength and Corrosion Resistance of Ti–50Zr Alloy Through Heat Treatment. DOI: 10.1002/adem.202501828

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the disadvantages of graphite furnace? High Cost, Slow Speed, and Complexity

- Why do thermocouples in high temperature vacuum furnaces have a limited lifespan? Learn to Extend Sensor Life

- What is the role of a constant temperature vacuum drying oven? Essential Electrode Sheet Processing Solutions

- What are the main technical parameters of vacuum pressure sintering furnaces? Key Specs for Advanced Materials

- What is the primary purpose of using a vacuum oven for PLA and EG pretreatment? Prevent Hydrolytic Degradation

- What advancements have been made in vacuum furnace energy efficiency and environmental impact? Discover Cleaner, More Efficient Heat Treatment

- What are drop-bottom quench furnaces used for? Achieve Rapid Quenching for High-Performance Alloys

- What is the purpose of using a high-vacuum system and annealing furnace for Mn–Ni–Fe–Si alloys? Unlock Data Accuracy