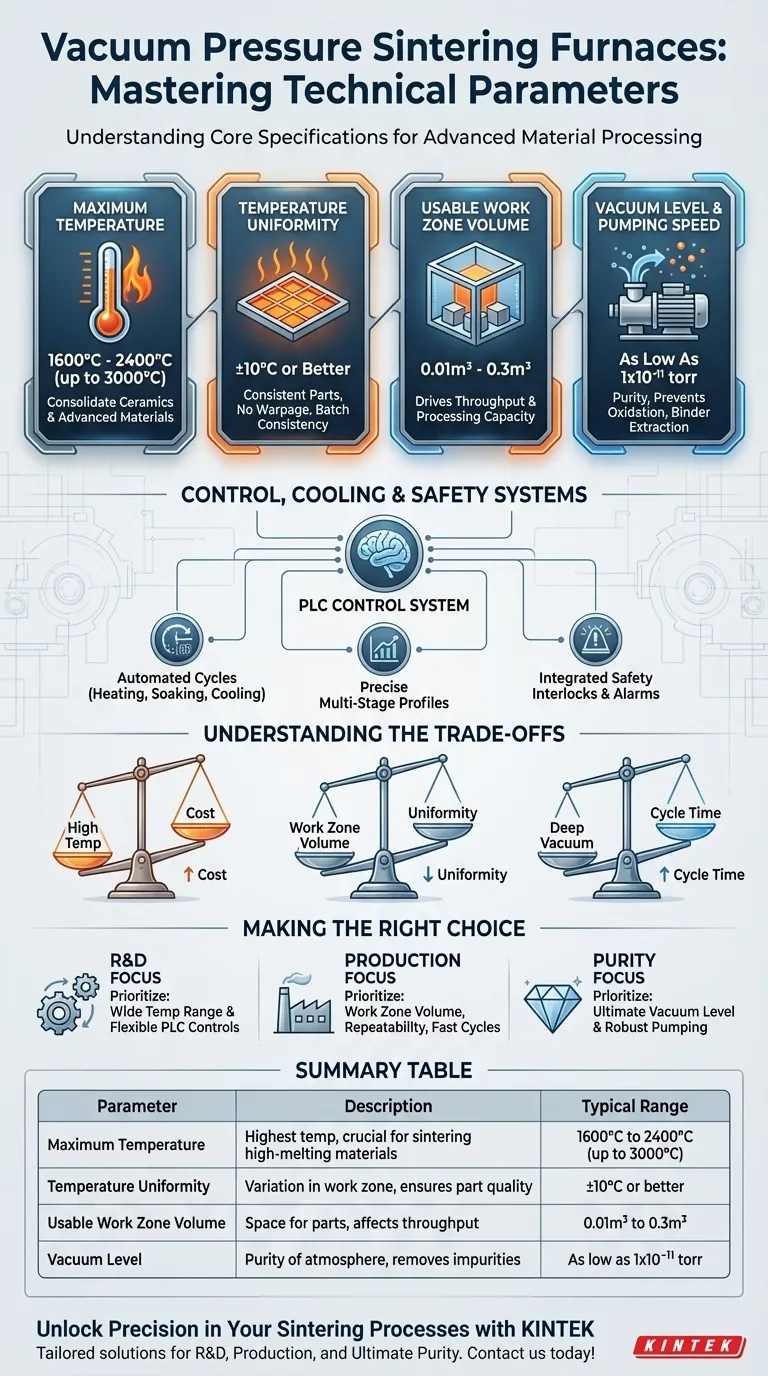

Understanding the core specifications of a vacuum pressure sintering furnace is the first step to mastering the technology. The main technical parameters are the maximum operating temperature, the usable work zone volume, the ultimate vacuum level, and the temperature uniformity within the heating zone. These four pillars dictate the furnace's fundamental capabilities for processing advanced materials.

A furnace's specifications are not just a list of numbers; they are a direct reflection of its ability to create a precisely controlled, impurity-free environment. Understanding what each parameter means is essential for achieving desired material properties and ensuring process repeatability.

Core Operational Parameters

The performance of any vacuum pressure sintering furnace is defined by a set of key metrics. These parameters determine the types of materials you can process and the quality of the final product.

Maximum Temperature

The maximum achievable temperature is arguably the most critical parameter, as it dictates the range of materials the furnace can sinter. Most commercial furnaces operate between 1600°C and 2400°C, with some specialized systems reaching up to 3000°C.

This high-temperature capability is necessary for consolidating ceramics, carbides, and other advanced materials with high melting points.

Temperature Uniformity

Temperature uniformity refers to the maximum temperature variation across the entire usable work zone. A common specification is ±10°C or better.

Excellent uniformity is non-negotiable for producing consistent parts. It ensures that every component in a batch, regardless of its position, undergoes the exact same thermal cycle, preventing warpage and inconsistent material density.

Usable Work Zone Volume

This parameter specifies the physical dimensions of the space available for placing parts, typically measured in cubic meters (e.g., 0.01m³ to 0.3m³).

It is a primary driver of throughput. A larger work zone allows for processing more parts per cycle, but it also presents a greater challenge for maintaining temperature uniformity and achieving a deep vacuum quickly.

Vacuum Level & Pumping Speed

The vacuum system is essential for creating a controlled, inert atmosphere. The vacuum level indicates the purity of this environment, with high-end systems reaching levels as low as 1x10⁻¹¹ torr. This prevents oxidation and removes atmospheric impurities.

Equally important is the pumping speed, which determines how quickly the furnace can reach the target vacuum and, crucially, how effectively it can extract by-products like evaporated binders during the debinding phase.

Control, Cooling, and Safety Systems

Modern furnaces are more than just hot, empty boxes. Their value lies in the sophisticated systems that manage the process with precision and safety.

The PLC Control System

A Programmable Logic Controller (PLC) is the brain of the furnace. It automates the entire heating, soaking, and cooling cycle.

This computer control ensures high repeatability from batch to batch, which is critical for industrial production. It also integrates all monitoring and safety functions into one centralized system.

Temperature Control and Cooling

Precise temperature management is achieved with intelligent digital controllers and strategically placed thermocouples. These systems can execute complex, multi-stage thermal profiles with high accuracy.

An internal pure water cooling system is vital for protecting the furnace shell and enabling rapid, controlled cooling of the product after sintering, which can shorten overall cycle times.

Integrated Safety Features

Safety is paramount when dealing with high temperatures and pressures. Furnaces are equipped with numerous automated safety interlocks managed by the PLC.

These include audible and visual alarms for over-temperature, over-current, and cooling water failure. Automatic door locks and emergency pressure release valves protect both the operator and the equipment.

Understanding the Trade-offs

Selecting a furnace requires balancing performance with practical constraints. No single configuration is perfect for every application.

High Temperature vs. Cost

Achieving temperatures above 2000°C requires specialized heating elements (like graphite) and advanced insulation. This significantly increases the initial cost and long-term maintenance of the furnace.

Work Zone Volume vs. Uniformity

As the size of the work zone increases, it becomes more difficult and expensive to engineer a heating system that can maintain strict temperature uniformity across the entire volume.

Deep Vacuum vs. Cycle Time

Pulling a very deep vacuum is a time-consuming process. While a higher-purity environment is beneficial, the time spent pumping down the chamber can reduce overall throughput, a key consideration in a production setting.

Making the Right Choice for Your Application

The ideal furnace specifications are determined entirely by your end goal. Use your primary objective to guide your evaluation of these technical parameters.

- If your primary focus is research and development: Prioritize a wide maximum temperature range and precise, flexible PLC controls to accommodate experimentation with diverse materials.

- If your primary focus is high-volume production: Emphasize work zone volume, process repeatability, and fast cycle times (efficient pumping and cooling).

- If your primary focus is ultimate material purity: The ultimate vacuum level and the pumping system's robustness for binder extraction are your most critical parameters.

Ultimately, matching the furnace's technical capabilities to your specific material and process goals is the key to successful sintering.

Summary Table:

| Parameter | Description | Typical Range |

|---|---|---|

| Maximum Temperature | Highest temperature the furnace can reach, crucial for sintering high-melting-point materials | 1600°C to 2400°C (up to 3000°C for specialized systems) |

| Temperature Uniformity | Variation in temperature across the work zone, ensuring consistent part quality | ±10°C or better |

| Usable Work Zone Volume | Space available for parts, affecting throughput and processing capacity | 0.01m³ to 0.3m³ |

| Vacuum Level | Purity of the inert atmosphere, preventing oxidation and removing impurities | As low as 1x10⁻¹¹ torr |

| Pumping Speed | Speed at which vacuum is achieved and by-products are removed, influencing cycle times | Varies by system, critical for efficiency |

Unlock Precision in Your Sintering Processes with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're focused on R&D, high-volume production, or ultimate material purity, our furnaces deliver superior temperature control, vacuum performance, and safety features to enhance your outcomes.

Contact us today to discuss how our tailored solutions can optimize your sintering applications and drive your success!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion